Module 5. Pasteurizers

Lesson 20

SOLVING NUMERICAL

20.1 Problem

Required: Milk pasteurizer, capacity 12,000 1tr/h

Inlet temperature 150C

Pasteurizing temperature 850C

Outlet temperature 40C

Holding time 15 sec. 50 ltr.

Regeneration 80%

Heat transfer area per plate = 0.375 m2

Overall heat transfer co-efficient for heating, regeneration and cooling and deep cooling are 2320, 2290, 2100 and 1800 (k.cal/m2 hr °C) respectively

Services Available :

24,000 l t r / h hot water of 90°C

18,000 l t r / h well water of 11°C

24,000 l t r / h chilled water of 1 °C

Branch to centrifuge at about 45 °C. Calculate the number of plates and pressure drop. Make suitable assumptions. For simplification of calculations, take specific heat of milk also as 1.0 k.cal / kg oC.

Solution

Assumption: Neglecting the reduction in volume.

When calculating plate requirement of pasteurizers we normally do not take into account the separation of cream in the centrifuge, which is about 10 %.

Calculation

A regeneration efficiency of 80% means that 80% of the heat is regained in the regenerating section.

In this case 80 (85 – 15) = 56°C rise in temperature

100

Milk at 15 oC inlet temperature is raised by 56°C in regeneration section, and milk outlet temperature will then be 15 + 56 = 71°C

The milk pasteurized at 85°C will be cooled down by the raw milk by 56°C and the milk entering the cooling section will be 85 – 56 = 29°C

So the complete temperature course will be:

15 – 71 – 85 – 29 – 15 - 4°C. (Assuming a minimum of 4°C temperature gradient between milk and well water)

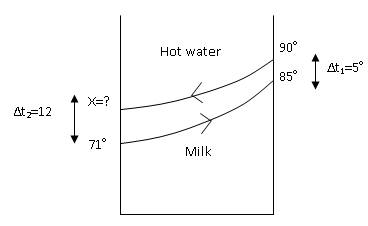

Pasteurizing Section

Heating by 24,000 l t r / h water of 90 °C

The LMTD calculations are

given below:

Applying heat balance X is calculated (temperature drop in hot water)

24000x1x(90-X) = 12000x1x(85-71)

X = 83

Equation for LMTD (Log Mean Temperature Difference)

![]()

![]()

= 8o

The LMTD diagram can be represented as:

![]()

For heat exchangers heat transfer rate is given as:

Q= UA![]()

Where,

Q = rate of heat transfer

A = Area of heat transfer

![]() = Log mean temperature difference

= Log mean temperature difference

Or

Q= UaN ![]() ..........(1)

..........(1)

Where,

A = area of one plate

N = number of plates

And since,

Q = m s Δt.......(2)

From equations 1 and 2

UaN tLMTD = m s Δt

N = ![]()

Arrangement

3 × 5 / 2 × 8 = 32 plates.

Here,

3 × 5

is for milk (3 passes and 5 channels)

2 × 8 is for hot water (2

passes and 5 channels)

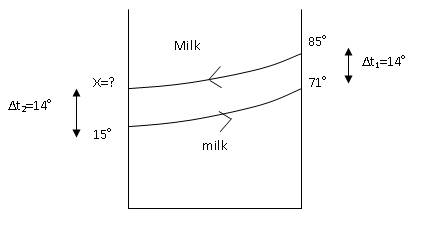

Regenerating Section

The LMTD calculations are given below:

We

know,

![]()

Since,

∆t2 = ∆t1 = 14 therefore we take the average value,

![]()

![]()

= 14

LMTD diagram can be represented as

![]()

We know,

UaN tLMTD = m

s Δt

![]()

Arrangement

6 × 5 / 6 × 5 = 61

However, in the entering

range 15 – 71 a branch to the centrifuge has to be provided as close as

possible to 45 °C.

Each group means a rise in

temperature of ![]()

If we make a branch after 3

groups the temperature there will be approximately 43°C.

Arrangement reg.

section I: 3 × 5 / 3 × 5 = 31 plates

Reg. section II: 3

× 5 / 3 × 5 = 31 plates

Cooling

By means of

18.000 l t r / h well water of 11 °C.

MwSwΔt = MmSmΔ

18000 x 1 x (11-X) = 12000 x 1 x (29-15)

X = 20o

![]()

![]()

![]()

= 6.1o

LMTD

diagram can be represented as:

![]()

t = 6.1 °C

We Know,

UaN tLTMD = m s Δt

![]()

Arrangement 3 × 6 / 3 × 6 = 37

Deep Cooling

By means of 24.000 l t r / h chilled water of 1°C.

MmSmΔt = McScΔ

12000 x 1 x (15-4) = 24000 x 1 x (X-1)

X = 6.5o

![]()

![]()

![]()

= 5.25o

LMTD diagram can be represented

as:

![]() t = 5.25 °C

t = 5.25 °C

N =

12000 × 11 × 1 =

36

0.375 × 1800 × 5.25

Arrangement 3 × 6 / 3 ×

6 = 37

Pressure Drops

Milk

15 × 1. 12 + 6 ×

0.78 + 28 × 0, 1 + 3 (holding section) = 27. 3 mwc

Hot

water 2 × 1. 75 + 3 ×

0.19

= 4. 1 mwc

Well

water 3 × 1. 75 + 4 × 0.

11

= 5. 7 mwc

Chilled

water 3 × 3. 00 + 4 × 0. 19

= 9. 8 mwc

20.2 PROBLEM :

Calculate

the number of plates in each section of HTST pasteurizer, for the following

data:

|

S. No. |

Parameters |

Milk |

Hot Water |

Chilled Water |

|

1 |

Flow Rate |

10,000lph |

30,000 lph |

30,000 lph |

|

2 |

Inlet temperature |

4°C |

85°C |

1°C |

|

3 |

Outlet temperature |

4°C |

-- |

-- |

|

4 |

Overall heat Transfer coefficient ‘U’ k.cal/m2 hr °C |

2320 |

2290 |

1800

|

Area of each plate is 0.375

m2; Regeneration Efficiency: 80%; Past. Temperature: 75°C

Soln:

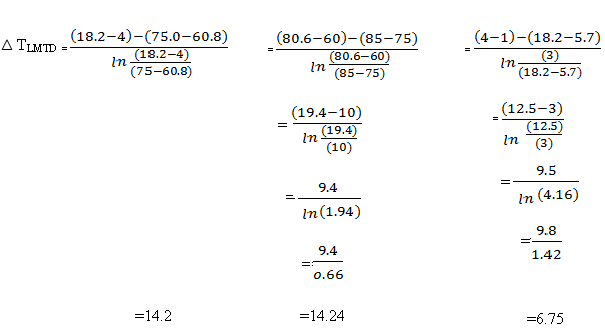

Regeneration Section

Regeneration 80/100 = (x-4)/75-4

X=60.8

Heat balance between raw milk and heated milk

10,000 x 0.93 x

(60.8-4) =10,000 x 0.93 x (75-x)

X=18.2

°C

Note: Remember that rate of heat is different than the heat balance

Heating Section:

Heat gained by milk = Heat lost by hot water

10,000 x 0.93 x

(75-60.8) =30,000 x1 x (85-X)

14.2/3 =

85-X

or

X=80.3 °C

Chilling Section:

Heat lost by milk = Heat gained by chilled water

10,000

x 0.93 x (18.2-4) = 30,000 x 1x (X-1)

X=5.7

Heat gained by raw milk in

Regeneration section is rate of transfer in that section

10,000 x 0.93 x (60.8-4) =

UA∆TLMTD

Fig.

20.1 Temperature profiles in various section of pasteurizer

Regeneration

Section:

Chilling

section

Heating section

Balancing the heat exchanged to the Rate of heat

transfer equation,

![]()

=43.3 or 44

plates

=11.26≈12

= 29

Answer: The number of plates required in Regeneration,

heating and chilling sections are 44, 12 and 29 respectively.

Role of Correction Factor

The above

calculations using LMTD, may not be the true

representative of counter current flow, as the milk and service fluid are

differing in the flow rates. To control the pressures on both sides to be

equal, the flow in the channels is made unequal. When the milk and

service fluid flow is in the ratio of the range of 0.66 to 1.5, it is possible

to have equal number of passes on both sides of the exchangers making the flow

to be counter current. When it becomes necessary to go for unequal passes due

to large differences in flow rates, it becomes necessary to apply significant

correction factor to take into account the non-counter current flow situation.

The extent

of LMTD correction depends upon several factors, including the number of NTU/pass

and number of channels per pass. Correction factor is required also

because, in the end zones of plates, heat is transferred only on one side, and

with even number of plates, one fluid has an extra stream or passage over the

other.

∆T LMTD cross

flow = F X ∆F LMTD

![]()

Where,

![]()

![]()

20.3 Problem

For

calculating the time taken for bringing up to pasteurization temperature in a

batch pasteurizer

|

Data: |

||||||

|

Pasteurization Temperature, Tp |

75 |

C |

Conductivity of vat wall , k |

13 |

||

|

Initial temperature of milk, To |

4 |

C |

Thickness of wall, x |

0.003 |

||

|

Temperature of Hot fluid |

85 |

C |

Co-eff of heat transfer, steam |

5000 |

||

|

Volume of Milk |

3 |

m3 |

Co-eff of heat transfer, milk |

860 |

||

|

Density of milk |

1030 |

kg/m3 |

|

|

|

|

|

Specific heat of milk |

0.93 |

k.cal kg C |

|

|

|

|

|

Area of heat transfer |

9.5 |

m2 |

|

|

|

|

|

Overal Heat transfer co-eff |

627.5258 |

k.cal/m2h C |

1.008369 h |

|

|

|

|

Time taken for heating, t = |

|

61 |

min |

|

|

|