Site pages

Current course

Participants

General

Module- 1 Engineering Properties of Biological Mat...

Module- 2 Physical Properties of Biomaterials

Module- 3 Engineering Properties

Module- 4 Rheological Properties of Biomaterials

Module- 5 Food Quality

Module- 6 Food Sampling

Module- 7 Sensory quality

Module 8. Quality Control and Management

Module 9. Food Laws

Module 10. Standards and regulations in food quali...

Lesson 32. Sanitation in food industry

Lesson 19. FOOD SAMPLING

Introduction 19.0

The term “food” refers to the broad range of edible materials that comprise the essential body nutrients required for life and growth, such as proteins, carbohydrates, fats, vitamins, or minerals. Foodstuffs are described variously as “liquid” or “solid”, and “wet” or “dry”, depending on the amounts of water and fat they contain. Samples of plant origin are classified for analytical purposes as having a high or medium water content and a lower content of saccharides (from 5% to 15%), very low water content (dry), or a high content of oils. Similarly, food samples can be divided into four main groups based on water and fat content.

Lot: A quantity of food or food units produced and handled under uniform conditions.

Sample: A number of food units that resembles the characteristics of the lot

A sample is a limited quantity of something which is intended to be similar to and represent a larger amount of that thing(s). The things could be countable objects such as individual items available as units for sale, or a material not countable as individual items.

19.1.1What is sampling?

“A procedure used to draw inferences about a lot (population) from results obtained from a sample”

“To collect a representative sample to obtain information on its status”

Sampling involves the selection of a certain portion, number of container and product units from a particular lot of the same food. It must be as representative as possible of the whole consignment or from lot.

An act of obtaining a sample is called sampling, which can be done by a person or automatically. Samples of material can be taken or provided for testing, analysis, inspection, investigation, demonstration, or trial use.

19.1.2 Objective:

Samples are usually collected from a lot of food for random surveillance, collection of data for a specific purpose, or monitoring/and to determine whether the food is unsatisfactory for any reason.

19.1.3. Importance of Sample Collection

The reliability of analytical data thus obtained depends on several factors, sampling being the major factor. Current analytical methods require only few grams of food sample to analyze. Thus, it is necessary that a sample be as representative of the population as possible.

19.2 Foods sampling

19.2.1 Food sample:

Food samples of biological origin (liquid or solid) have been divided generally into the five categories described in Table 19.1. This coarse division is important when considering the choice of isolation technique, extraction solvent, and sample clean-up method during an analytical procedure.

Moisture content is an important consideration during sampling procedures, in part because it affects the extent of sample heterogeneity. Virtually all foods are heterogeneous, and the analyst should be familiar with their variability in composition and structure. In general, fresh foods of plant origin are more variable in composition than fresh foods of animal origin. The analyst should be also aware of the postmortem or postharvest physiological changes that can occur after a fresh food is sampled and which can affect sample heterogeneity. A combination of cold storage and chemical preservation may be required to maintain sample integrity in the event of prolonged storage.

Table 19.1: General classification of food samples according to their content

|

Sample |

Character |

Typical analytes |

|

Milk |

Aqueous, proteins, lipids |

Veterinary drugs, toxic elements, pesticides, industrial contaminants |

|

Eggs |

High lipids and albumin content |

Veterinary drugs , pesticides, industrial contaminants |

|

Other samples of animal origin (liver, fat) |

Various fat, proteins, or water |

Drugs, pesticides, industrial contaminants |

|

Plant materials (fruits, vegetables) |

Various water, plant pigments, proteins, lipids, essential oil, waxes |

toxic elements, pesticides, industrial contaminants |

|

Food (meat, milk, cereals, wines, juices, plants oils, sugar |

Various fat, oils, lipids, proteins, sugar, starch, water, or pigments |

pesticides, industrial contaminants, synthetic colorants, additives, synthetic sweeteners, antioxidants |

Although the chemical and physical properties of foods are inherently variable, even between samples that originate from the same breed or strain, the variability in composition of a single food sample can be minimized with proper sampling and sample pretreatment techniques. Two approaches can be used for sampling a food mass that is larger than the amount required for analysis in the laboratory. Many minute increments of a solid material can be collected and blended to represent the entire foodstuff, or a quantity of material that is large enough to be compositionally representative of the whole can be collected and then reduced to a fine mixture before being sub-sampled. The first approach is usually avoided, since it is difficult to obtain a statistically representative sample and the sampling time can also be very long. The latter approach is more practical, accurate, and reproducible.

Since virtually no food material can be analyzed in its entirety, careful sampling techniques are required to obtain representative, laboratory-sized primary samples, in addition to subsequent subsamples, or secondary samples. The amount of subsample required for an analytical procedure usually varies from a fraction of a gram to several grams.

19.2.2 Sample Size

The required sample size is defined in part by the nature of the target compound, that is, to what extent the analyte is retained in the matrix. Xenobiotics are generally present at trace levels. A sufficiently large amount of sample must be collected and analyzed in order to be able to measure minute quantities of the compound of interest and to satisfy the method’s limit of detection. Conversely, relatively small samples may be collected for the macro analysis of gross food components, i.e., to measure crude fat, crude protein, crude fiber, or ash. Although proximate analysis of these food components is sometimes sufficient, more exact analyses are usually required.

The sample size is also dependent on the relationship that exists between the mass required to adequately represent a sample and the characteristics of that sample. If a foodstuff consists of some mixture of different-sized particles, enough sample mass needs to be collected in order to adequately represent all of the particles. Because large particles are more difficult to represent than smaller ones, a mass that is large enough to represent the larger particles will also be representative of the smaller ones. The segregation of finer, denser particles to the bottom of the sample container must be recognized during the sampling process to ensure that all particles are represented and to avoid large sampling errors.

19.3 Sampling Steps

19.3.1 Sample collection

Containers

Sampling devices

Sampling procedures: aseptic technique

Sample labeling

Techniques:

Food lots are sampled in either a manual or continuous manner in order to obtain a representative specimen. Containers holding loose foodstuffs can be sampled manually with devices that trap the material in a compartment such as a probe or tube. Slots or openings placed at intervals in the tube allow for simultaneous sampling at different depths of the product. When employing this technique, however, the analyst must consider the segregation effect and ensure that all particle sizes are accessible. The foodstuff may ultimately need to be removed from the sample-container and poured onto a flat surface. The amount of material may then be reduced with a coning-and-quartering method, and a subsample collected in multiple random increments. No particle size should be excluded during the sampling process. Since food components or contaminants that collect in certain-sized particles might be omitted from the final analysis, thereby resulting in an increase in sampling error.

Large mixtures may also be reduced with a riffle cutter, which is a box-like device that has equally spaced dividers to divide the sample stream. The sample may be further cut or quartered by passing it through successive riffles. Other proportional dividers are available for reducing a sample, such as the straightline sampler and the spinning riffle sample divider.

Uniformly solid or liquid products are perhaps the most straightforward to sample. Drill-type devices are used to obtain a core from solid products such as cheese or frozen foods. Liquid samples are thoroughly mixed before a subsample is removed with a syringe-type sampler or by submerging a container under the liquid’s surface (a so-called “grab” sample). For obvious reasons, ‘many complex foods such as vegetables, fruit, or animal tissues may require blending prior to being sampled.

Throughout the sample preparation procedure, it is essential for the analyst to recognize the necessity of utilizing methods that satisfy statistical sampling and analysis requirements. The inherent variability in the composition of raw materials, basic ingredients, and processed foods requires the use of statistical methods for obtaining representative and replicate samples, and for estimating the error involved in sampling.

19.4 Food pretreatment:

19.4.1. Removal of extraneous matter:

Before sample blending is done, it is often necessary to wash, remove, or drain irrelevant extraneous matter. Soil or sand that adheres to fresh fruit or vegetables can be removed by washing or wiping the surface of the produce; however, excessive washing should be avoided to prevent the leaching of soluble solids.

Depending on the objective of the analysis, fresh produce may be separated into the core and the outer and inner tissues. Shells are usually separated from nut kernels and pits from stone fruits. Large fish are cleaned, scaled, and eviscerated, while small fish can be blended whole. Shellfish are shucked, eggs are broken to isolate the liquid interior, and meat is removed as completely as possible from bone. Canned fruit and vegetable products may be drained through screens if it is not necessary to analyze the composite sample.

19.4.2. Sample reduction

Once a food sample has been collected using the sampling techniques a suitable method is required to make the material less heterogeneous. Various approaches may be utilized for reducing the particle weight and size in a primary sample, so that smaller subsamples can be taken for a representative analysis of the whole. Finely divided materials also dissolve faster and are easier to extract because of their greater surface area.

Methods for reducing solid or semi-solid foods include mechanical grinding, mixing, rolling, agitating, stirring, chopping, crushing, macerating, mincing, pressing, pulverizing, or any other reasonable means of cornminuting the sample.

Sample reduction can also be achieved with a Wiley or ball mill, mortar and pestle, mechanical high-speed beaters or blenders (for soft or wet foods), and meat grinders.

19.4.3. Sample handling

Transportation

Reception

19.4.4. Sample analysis

Withdrawing analytical units

Homogenization of analytical units/ Analysis using appropriate methods and instruments

19.5 Types of Sampling

19.5.1 Bulk sampling

It involves the selection of a sample from a lot of material that does not consist of discrete, identifiable or constant units. Sampling may be performed in static or dynamic situations. Bulk sampling poses special problems requiring certain decisions to be made: the number of increments to be taken, the size of the increments, from where in the pile or stream they should be drawn, the sampling device to be used, and how to reduce the increments taken to a reasonable size of ample for delivery in the laboratory.

19.5.2 Acceptance sampling

It differs from the bulk sampling and involves the application of predetermined plan to decide whether a lot of goods meet defined criteria for acceptance. The risks of accepting ―bad‖ or rejecting "good‖ lots are stated in conjunction with one or more parameters. Statistical plans can be designed to regulate the probabilities of rejecting good lots or accepting bad lots.

Sampling Plan

The particular choice of sampling procedure to determine the minimum number of food units that will provide a high degree of certainty about the quality of a food lot.

Sample units (n)

1. Large enough to represent the population

2. Small enough to be economically feasible

Sample characteristics

The material may be solid, liquid, gas, material of some intermediate characteristics such as gel, tissue, organisms, or a combination of these. Even if a material sample is not countable as individual items, the quantity of the sample may still be describable in terms of its volume, mass, size, or other such dimensions. A solid sample can come in one or a few discrete pieces, or can be fragmented, granular, or powdered.

19.6 Solid food sampling:

19.6.1 Samplers for general usage:

Sampling from bulk: Use appropriate apparatus for obtaining increments from static bulk (example, hand- held spears, mechanical or air-assisted apparatus).

Sampling from bags: Use sack type spears.

Mixing and dividing: Use shovels and dividing apparatus or automatic random dividing apparatus.

19.6.2 Sampling from silos, bins or warehouses:

Increments shall be taken throughout the whole depth of the lot. Suitable instruments must be used to achieve this requirement. If the depth of the lot does not permit use of this method, sampling should be carried out from the flowing cereal in accordance with ISO 6644.

Take the square root of the tonnage in the static bulk. Divide by two and round up to the next whole number. This is the minimum number of increments that is to be obtained.

Example: Number of increments for bulk grain of more than 500 t

|

tonnage |

500 |

1000 |

2000 |

4000 |

6000 |

8000 |

10000 |

|

Square root |

22.4 |

31.6 |

44.7 |

63.2 |

77.4 |

89.4 |

100 |

|

Number of increments |

12 |

16 |

23 |

32 |

39 |

45 |

50 |

Sampling from bags: Unless otherwise specified in the contract or unless the practice at the port or elsewhere requires otherwise, increments shall be taken from different part of a bag (for eg. Top, middle, bottom) by means of a sack/ bag spear from the number of bags specified in table

| Number of bags in consignment | Number of bags to be sampled |

|

Up to 10 10 to 100 More than 100 |

Each bag 10, taken at random Square root (approx.) of total number, |

Sampling Scheme for consignment of more than 100 bags.

The consignment shall be dividing into (n-1) groups containing n or (n-1) bags: the remaining bags constitute a group.

Examples:

A consignment comprising 200 bags.

The square root of 200=14.142, therefore n=14: ---makeup 14 group of 14 bags (i.e. total of 196 bags); ---Draw up a list from 1 to 14; cross out one number, for e.g. 7; ---Sample the seventh bag from each group of 14 bags; ---the remaining group (i.e. 4) is smaller than 14 bags, so sample one bag from this group at random. A total of 15 bags have thereof been selected.

A consignment comprising 2000 bags

The square root of 2000=44.721, therefore n=45: ---make up 44 groups of 45 bags (i.e. total of 1980 bags); ---draw up a list from 1 to 45; ---cross out one number, for example 20; ---sample the 20th bag from each group of 45 bags; ---the remaining group (i.e. 20) is smaller than 45 bags, so sample one bag from this group at random. A total of 45 bags ha therefore been selected.

Reduction of the Sample to Analytical Size

The two common methods of reducing bulk samples to a practical size are riffling and quartering. The sample is fed onto the top of the riffle and as it falls through the device the sample is divided equally into two bins. When the operation is complete, the contents of one bin is discarded and the other passed through the riffle again. In this way the sample is progressively and randomly halved until its bulk is reduced to that required for laboratory work up. The riffle, due to its design is extremely difficult to clean and therefore it is practical to arrange for an individual riffle should be permanently kept for use with a specific material.

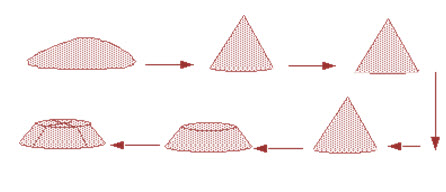

Sample Quartering:

The total sample is placed on a clean impervious surface and formed into a cone by shoveling. Each shovel full is placed on the top of the last so that the material runs down the side of the pile and is thereby distributed around the sides of the pile as evenly as possible (if larger pieces of material roll away from the base of the cone they must be pushed back to the edge). From the first cone two successive cones are sequentially made in the same manner (this is to mix the sample well). The third cone is then flattened to a uniform thickness and then quartered along two diameters. One diagonal pair of quarters is rejected. These four stages are repeated until a sample of the required size is obtained. If the initial bulk sample is very course then the average particle diameter made need to be reduced by grinding between each quartering procedure.

19. 7. Instruments for different types of product and storage states.

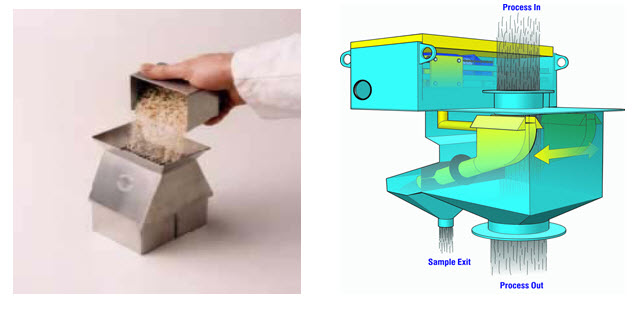

Sample dividers:

Ideal for Free Flowing Powders Suitable for use with powder chemicals, food stuff, feed and similar granular materials These hand held sample dividers will subdivide material samples into smaller portions by single or multiple passes. The important feature of Endecotts sample dividers is that each subdivision retains the characteristics of the original sample.

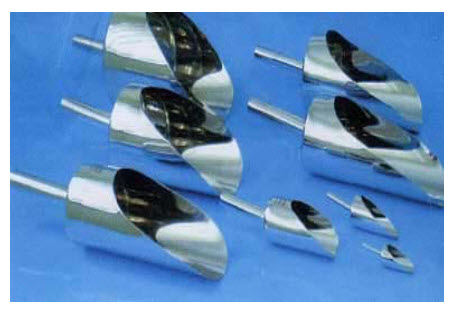

Sample Scoops

These Heavy Duty Sample Scoops are produced to the highest quality, are crevice free to minimise contamination and easy to clean.

Sleeve Sampler :

Ideal for Free Flowing Powders Suitable for use with powder chemicals, food stuff, feed and similar granular materials Ideal for sampling large volumes at great depths. At the required depth pull up the sampler slightly. This will force the sleeve down so that the product can fall into the sample chamber

The Sampling Spear

Powder, Granules or Crystals:

Samples of powders granules or crystals are usually taken with a ‘spear The spear is thrust at an angle into the material (the opening underneath) rotated two or three times and then carefully withdrawn with the opening uppermost. The contents are then discharged into the sample container.