Site pages

Current course

Participants

General

MODULE 1. FLUIDS MECHANICS

MODULE 2. PROPERTIES OF FLUIDS

MODULE 3. PRESSURE AND ITS MEASUREMENT

MODULE 4. PASCAL’S LAW

MODULE 5. PRESSURE FORCES ON PLANE AND CURVED SUR...

MODULE 6.

MODULE 7. BUOYANCY, METACENTRE AND METACENTRIC HEI...

MODULE 8. KINEMATICS OF FLUID FLOW

MODULE 9: CIRCULATION AND VORTICITY

MODULE 10.

MODULE 11.

MODULE 12, 13. FLUID DYNAMICS

MODULE 14.

MODULE 15. LAMINAR AND TURBULENT FLOW IN PIPES

MODULE 16. GENERAL EQUATION FOR HEAD LOSS-DARCY EQ...

MODULE 17.

MODULE 18. MAJOR AND MINOR HYDRAULIC LOSSES THROUG...

MODULE 19.

MODULE 20.

MODULE 21. DIMENSIONAL ANALYSIS AND SIMILITUDE

MODULE 22. INTRODUCTION TO FLUID MACHINERY

LESSON 32. INTRODUCTION TO FLUID MACHINERY

What is Fluid machine?

-

A fluid machine is a device which converts the energy stored by a fluid into mechanical energy or vice versa. The energy stored by a fluid mass appears in the form of potential, kinetic and intermolecular energy. The mechanical energy, on the other hand, is usually transmitted by a rotating shaft.

-

Machines using liquid (mainly water, for almost all practical purposes) are termed as hydraulic machines.

-

The fluid machines use either liquid or gas as the working fluid depending upon the purpose.

-

The machine transferring mechanical energy of rotor to the energy of fluid is termed as a pump when it uses liquid, and is termed as a compressor or a fan or a blower, when it uses gas.

-

The compressor is a machine where the main objective is to increase the static pressure of a gas. Therefore, the mechanical energy held by the fluid is mainly in the form of pressure energy.

-

Fans or blowers, on the other hand, mainly cause a high flow of gas, and hence utilize the mechanical energy of the rotor to increase mostly the kinetic energy of the fluid.

-

In these machines, the change in static pressure is quite small.

-

For all practical purposes, liquid used by the turbines producing power is water, and therefore, they are termed as water turbines or hydraulic turbines . Turbines handling gases in practical fields are usually referred to as steam turbine, gas turbine, and air turbine depending upon whether they use steam, gas (the mixture of air and products of burnt fuel in air) or air.

Fluid machine may be divided into two groups;

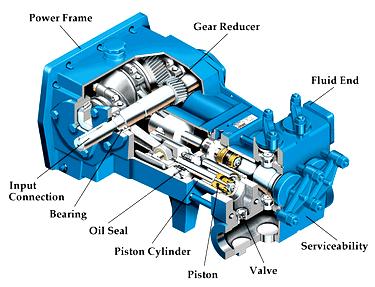

A) Positive displacement

piston pump

peristaltic pump

gear pump

two-lobe rotary pump

screw pump

Jet pumps

B) Turbomachines

axial-flow (propeller pump)

radial-flow (centrifugal pump)

mixed-flow (both axial and radial flow)

Positive displacement machines

-

can produce very high pressures

-

hydraulic fluid pump

-

high pressure water washers

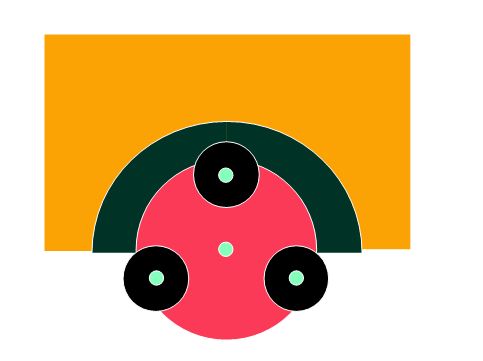

Peristaltic Pump

Fluid only contacts tubing

Tubing ID and roller velocity with respect to the tubing determine flow rate

Tubing eventually fails from fatigue and abrasion

Fluid may leak past roller at high pressures

Viscous fluids may be pumped more slowly

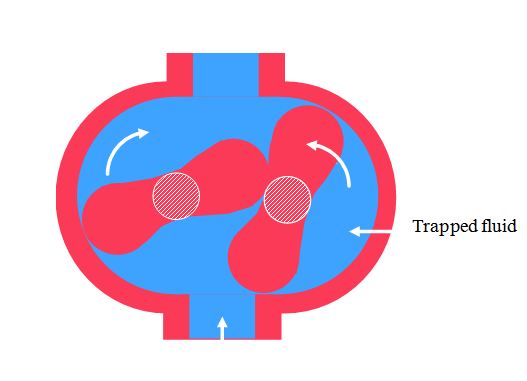

Rotary Pumps

- Gear Pump

- fluid is trapped between gear teeth and the housing

- Two-lobe Rotary Pump

(gear pump with two "teeth" on each gear)

same principle as gear pump

fewer chambers - more extreme pulsation

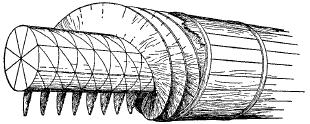

Screw Pump

Screw Pump

-

Can handle debris

-

Used to raise the level of wastewater

-

Abrasive material will damage the seal between screw and the housing

-

Grain augers use the same principle

Rotadynamic machines (Turbomachines)

-

All rotodynamic machines have a rotating component through which the fluid passes. In a turbine this is called the rotor which has a number of vanes or blades.

-

The fluid passes through the blades and drives the rotor round transferring tangential momentum to the rotor

-

Rotodynamic machines are smooth and continuous in action with a consequent pulsation free flow from pumps and smooth rotation from turbines. In the event of pump discharge flow being suddenly stopped there are no high shock loads. Positive displacement machines can easily be damaged if a discharge valve is suddenly closed. Rotodynamic pumps are ideal for high flow low discharge head duties and provide compact reliable solutions.

-

Some of the important rotadynamic machines are as below:

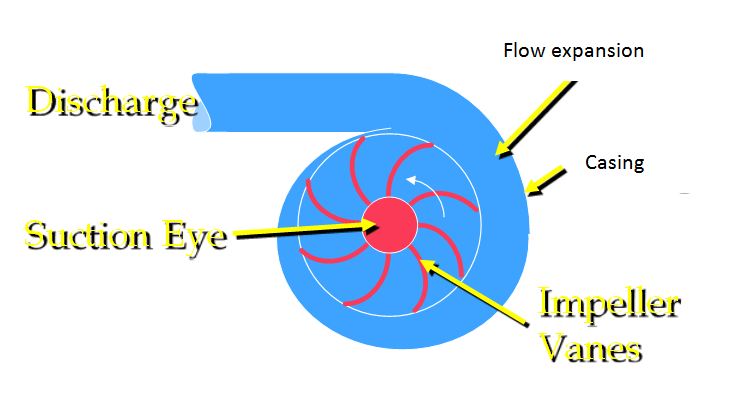

Radial Pumps (centrifugal pump)

-

also called centrifugal pumps

-

broad range of applicable flows and heads

-

higher heads can be achieved by increasing the diameter or the rotational speed of the impeller

Axial Flow

-

also known as propeller pumps

-

low head (less than 12 m)

-

high flows (above 20 L/s)

-

Turbines and pumps

A turbine directly converts fluid energy into rotating shaft energy.

If the fluid motion is converted, initially to reciprocating mechanical motion the machine is an engine e.g and internal combustion engine or a steam engine ).

A machine for converting mechanical energy into fluid flow is called a pump...

Compressors or Fan

If the machine converts mechanical energy to increase the potential energy of a compressible fluid by increasing its pressure the machine is called a compressor. If the machine is primarily provided to increase the kinetic energy of a compressible fluid e.g. air, the machine is a fan. With a fan or blower the pressure head developed is usually relatively small and fluid calculations can often be done assuming the fluid is incompressible.

Positive Displacement Machines

A pump can be a positive displacement machine or a rotodynamic machine Ref. Pumps Positive displacement machines are designed such that there is virtually zero fluid slippage in the energy transfer process. The general principle of these type of pumps is that fluid is drawn into a chamber at a low pressure. The inlet to the chamber is closed and the outlet is opened, and the fluid is then forced out of the chamber by reducing its volume.

The type of pump can be used to generate very high pressures in a compact mechanical envelope. The main disadvantage is that the operation is an intermittent one resulting in a high level of pressure fluctuation throughout the operating cycle.