Site pages

Current course

Participants

General

Module 1. Dairy Development in India

Module 2. Engineering, thermal and chemical proper...

Module 3. Unit operation of various dairy and food...

Module 4. Working principles of equipment for rece...

Module 5. Dairy plant design and layout, compositi...

Module 6. Deterioration in products and their cont...

Module 7. Physical, chemical and biological method...

Module 8. Changes undergone by the food components...

Module 9. Plant utilities requirement.

References

Lesson 7. Unit operation of various dairy and food processing systems-II

7.1 Heat Exchanging

Heat exchanging is one of the most important unit operations of any food industry. Every industry must able be to control the temperature of products at every stage in the process. Heating and cooling are therefore very common heat transfer operations in the dairy/ food plant

7.1.1 Heating

We heat foods for many different reasons among them the major reasons are to cook the food for better palatability and tenderness, to destroy microorganisms and to preserve it. For example, baking of bread, pasteurization of milk and canning of vegetables. Others are heated to drive off moisture and develop flavors, as during the roasting of coffee and toasting of cereals. Some food ingredients, such as soybean meal, are heated to inactivate natural toxic substances.

Heating of foods is carried out by conduction, convection, radiation, or combination of these. Most foods are heat sensitive and prolonged heating causes loss of nutritional values, formation of dark colors and burnt flavours. Rapid heating can destroy microorganisms faster than it causes undesirable chemical reactions. Since microorganisms are more sensitive to rapid heating than are chemical reactions, hence, it is desirable to heat and cool foods rapidly to maintain optimal quality. Rapid heating is achieved by giving maximum contact with the heating source. This may be accomplished by dividing the food into thin layers in contact with heated plates as in the plate-type heat exchanger used to pasteurize milk. The milk flows across one side of the plates while hot water or steam heats the other side. Such plate heat exchangers can be used for rapid cooling with cold water or brine instead of hot water. But the limitation with plate heat exchanger is that it can only be used with liquid foods. A jacketed tank or kettle with steam/ hot water circulated in the jacket is another way of heating liquid foods. It can also be used to heat foods with suspended solids like vegetable soup. The soup is kept moving with an agitator for uniform heating and to avoid burning onto the kettle wall.

For in-can or in-bottle sterilization of foods, they must be heated to temperatures higher than the boiling point of water to sterilize nonacid foods and to achieve that large pressure cookers or retorts are used. High pressure is used to obtain the high temperature needed using pressure cookers of heavy construction to withstand this pressure. Another type of retort employs mechanical agitation for better convection of heat within individual cans, where the outside of the cans are heated by conduction from steam. For roasting coffee beans or nuts, many kinds of heaters are being used. In one type, the beans or nuts move from overhead hoppers into cylindrical vessels that turn and keep the beans in constant motion for even heating. These vessels may be heated from within by circulating heated air or with radiant heat from the vessel walls and the exterior by contact with hot air, gas flame or steam. In some instances this type of roaster is replaced with tunnel ovens in which the coffee beans or nuts pass on moving belts or are vibrated beneath radiating infrared rods or bulbs. Whatever the method, precise control of temperature is essential for proper roasting. Foods may be heated or cooked using toasters, direct injection of steam, direct contact with flame, electronic energy as in microwave cookers and so on; all of these methods are currently used in the food industry. Processes such as baking, frying, most food concentration, food dehydration and various kinds of package closure all employ the unit operation of heating.

7.1.2 Cooling

While heating is the addition of heat energy to foods, cooling is the removal of heat energy. This may be done to the level where food is chilled to refrigeraton temperature, or beyond the freezing point. Primarily, food is refrigerated and frozen to enhance its keeping quality. But there are some foods that owe their entire character to the frozen state. A prime example is ice cream. A mixture of milk and cream are cooled by passing them in thin layers through heat exchangers by allowing the liquids to run down over the surface of a hinged leaf cooler. Within the leaves are pipes through which cold water or refrigerant is pumped. Liquid egg, apple slices and other fruits in 13.6 kg cans are commonly frozen solid in an air-blast freezer or sharp freezer room maintained at about -26°C. The cans are kept with certain space allowing the cold air to be circulated by fans/blowers, between them to speed up the freezing operation. Such products are mainly sent to bakeries for use after thawing.

There are many kinds of commercial air-blast freezers designed to freeze peas, beans and other vegetables as individual pieces. In one type, the peas are loaded on trays that are automatically moved upward through a cold air blast. After freezing, the peas are removed from the trays and conveyed under cold air to packaging equipment. The trays return to initial position under the pea hopper to receive next batch and the cycle is repeated.

Freezing of canned or packaged foods may be done by direct immersion in a refrigerant. Here the cans may be agitated as they pass through the refrigerant within a cylindrical shell or tube, to increase the rate of heat transfer. The value of quick freezing to food quality has led to the use of liquid nitrogen with its extremely low temperature of -196°C.Many food plants have installed large liquid nitrogen tanks and pump liquid-nitrogen to freezers where it is sprayed directly onto foods to be frozen. Delicate products such as mushrooms/strawberries are frozen this way.

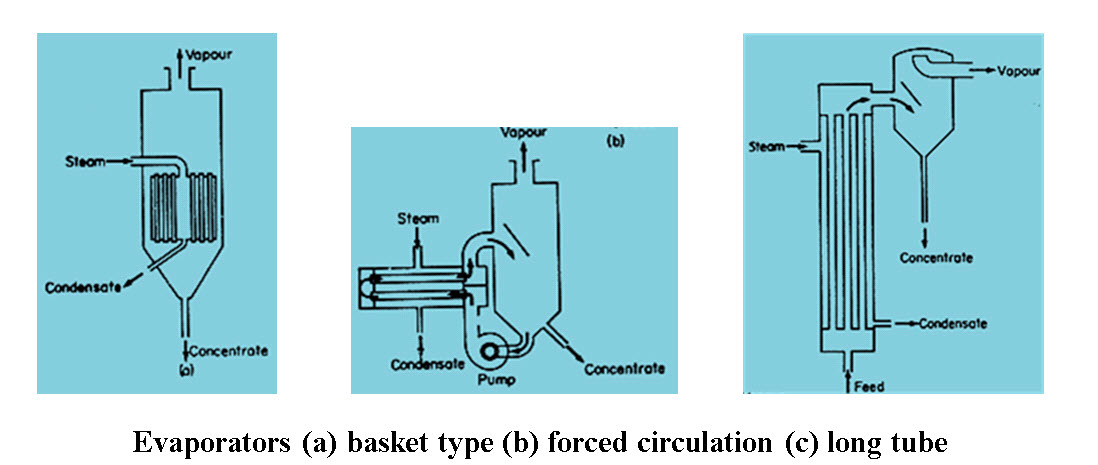

7.2 Evaporating

In food industry, evaporation is used principally to concentrate liquid foods by the removal of water and also to increase the shelf life of the food to certain extent. It is also used to remove undesirable volatiles and to recover desirable food volatiles.

The simplest and natural evaporation is the evaporation of sea water due to heat of sun and production of salt as a residue. Grapes and other fruits can be dried using sun drying. Another simple form of evaporation occurs when water and sugar is boiled in a heated kettle to make sugar syrup, as is common in candy-making. However, this requires considerable energy in the form of heat for a long period of time, which may cause damage to products which are heat sensitive, such as milk or orange juice.

The boiling point of all liquids is depressed as pressure decreases and this is the key to modern evaporation processes. If a heated kettle is enclosed and connected to a vacuum pump, one has a simple vacuum evaporator. Such evaporators are generally used to remove water from sugar cane juice in the early stages of crystalline sugar production.

The level of vacuum in the evaporator is kept amplified gradually in subsequent stages through which the liquid food passes. Irrespective of design, major objective of vacuum evaporators is to remove water at temperatures low enough to avoid heat damage to the food. In multiple stage evaporators, we can easily remove water at 50°C and some are designed to boil off water at temperatures as low as 21°C. Milk is generally evaporated to a total solids content of 40%, before it is dried, to avoid nutritional damage, energy loss and physical damage.

7.3 Drying

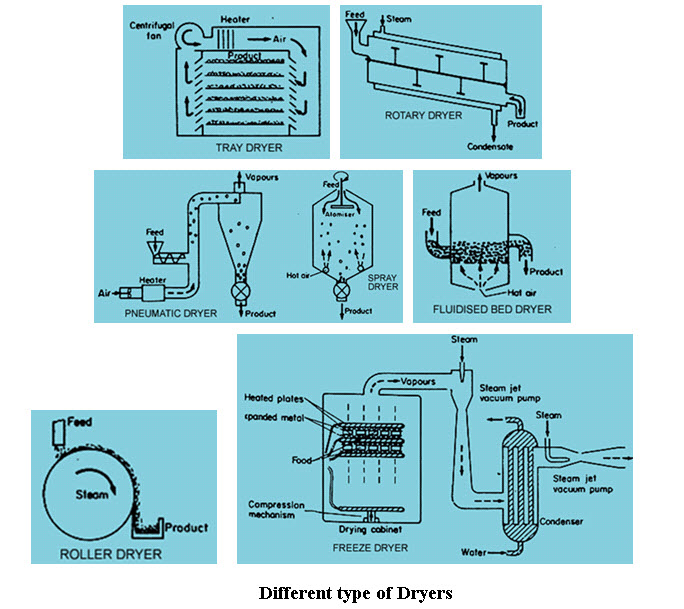

In drying, the major objective is to remove as much water as possible with minimum damage to the food. In case of evaporation foods are concentrated two to threefold whereas, driers will take foods very close to nil moisture or in many cases less than 2% or 3% water. Driers are installed to prepare well-known products such as dried milk powder and instant coffee. Although food has traditionally been dried to preserve it for longer time as well as to reduce its bulk, some foods are dried as convenience items and for their novelty appeal; an example is freeze-dried fruits for cereals.

Foods in liquid form such as milk and chunk forms like shrimp or steak may be dried. It is generally much easier to dry liquid foods because these are easier to subdivide (both as a spray or a film) and in a subdivided form, the moisture can be removed more quickly. Subdivision of a liquid to increase the surface area is the principle behind the widely used spray drier. Liquid foods like milk, coffee or egg yolk is first concentrated to desired level and then pumped into the top of the large drying chamber, where the liquid is atomized by a spray nozzle or equivalent device. The chamber is incorporated with the hot air from the entry points kept in the drying chamber depending upon the product to be dried. The hot air in contact with the fine droplets of food dries the droplets and dehydrated particles are collected at the bottom of the drying chamber. The moisture removed with hot air during drying is exhausted separately.

Drying food by making a thin film is commonly done on a drum or roller drier. The single or double drums are heated from within by steam on which the layer of food applied that loses the moisture immediately. The dried food is then mechanically scraped from the drum with long knives. Mashed potatoes, tomato puree and several milk products are preferably dried this way.

Small pieces of food such as peas and diced onions can be dried by passing them through a long tunnel dryer. However, overheating and shrinkage may result into poor quality products in the case of heat sensitive foods such as chunk foods where a milder method like vacuum freeze-drying is employed. There are many kinds of vacuum freeze-driers where, all types of food pieces are first frozen and then dehydrated under vacuum from the frozen state. Under the conditions of high vacuum ice portion of food directly sublimates. This is very gentle kind of drying protects majority of food quality attributes such as texture, color, flavor and nutrients. Freeze-drying can be easily done for solid or particulate foods without any restriction. Several Direct Vat Set Starter cultures, brewed coffee and nutritional and fresh like juice products are dehydrated by freeze-drying.

7.4 Forming

Foods are most often formed into specific shapes for convenience and attractiveness. For example, hamburger patties are formed by gently compacting ground beef into a disk shape in various types of patty-making machines, which apply controlled pressure to the beef within an appropriate form. Pressure is controlled to avoid the hamburger become overly tough or loose after cooking. Uniform pressure is essential or patties will vary in weight. Pressure extrusion through dies of various shapes forms dough into spaghetti and other pasta shapes for subsequent oven drying.

In the ice-cream industry, besides extrusion, frozen ice-cream is formed by filling in mold in which chocolate and nuts may be added followed by cooling and hardening. Some confectionaries and food tablets may be formed from powdered ingredients by the application of intense pressure in specially designed tableting machines. Sometimes, as in the case of malted milk tablets, an edible binding agent is required to hold the malted milk powder together. When the powders are high in certain sugars or other thermoplastic food constituents, an additional binding agent is not required. Here high pressure during tablet forming produces heat, melting some of the sugar or other thermoplastic material, which on cooling helps fuse the powdered mass together. This is one way to form fruit juice tablets from dehydrated fruit juice crystals. Some tablet-forming machines also may employ additional heat beyond that generated by pressure. The table butter and cheese are packed in the form of cubes or blocks by this operation only.

7.5 Fermentation

Fermentation is a process in which microorganisms generate energy by oxidizing carbohydrates and related compounds. It has been used since ancient times as important method of food preservation. Vegetables, fruits, cereals, milk and other food materials have been treated in special ways in order to promote the growth of beneficial microorganisms while inhibiting the growth of deteriorating and pathogenic microorganisms. Fermentation preserves the food and it also enhances the digestibility, taste, aroma, texture and nutritional value of the product. The fermentation end products like lactic acid, acetic acid, alcohols, antimicrobial substances, etc. provide the preservation effect to the fermented products. Besides lowering the pH, organic acids are also toxic for many microorganisms. It is also important that the fermentable carbohydrates are completely utilized by the fermenting microorganisms and thereby made unavailable for the undesirable microorganisms. In some products the addition of salt also increases the shelf life of the products by lowering the water activity. The natural habitats of lactic acid bacteria, yeast and molds are most often plant materials. However, the type of organisms can vary considerably depending on type of plant, climatic conditions and available nutrients in the raw material. During some fermentations (e.g., fermentation of plant material such as cabbage, cucumbers, olives, soya beans and coffee), several different types of microorganisms are required at various stages of the fermentation process. In other fermentations (e.g., production of yogurt and beer), only a few different microorganisms are required.

7.6 Packaging

The major objectives of food packaging include containment for shipping, dispensing and unitizing into appropriate sizes and improving the usefulness of the product. The primary goal of packaging is to protect the product from microbial contamination, physical dirt, insect invasion, light, moisture pickup, flavor pickup, moisture loss, flavor loss and physical abuse.

Foods are packaged in metal cans, glass and plastic bottles, paper and paperboard, a wide variety of plastic and metallic films or combinations of these. Continuous automatic machines sometimes at speeds of more than 1000 units per minute are used for packaging. Many food products were earlier being filled into rigid metal and glass containers are now being replaced with flexible and formable materials. Filling and capping machines are being joined by more sophisticated systems. Much of the consumer milk supply is now packaged in multi-layer paper cartons. Containers are automatically formed from stacked paper flats, volumetrically filled and sealed by passing the upper flaps through heated jaws, which melt the plastic coating and thus provide sealability. In recent years, paperboard cartons coated with special plastics which have good barrier to oxygen are widely used for orange juice and similar products.

Other machines form pouches from rolls of plastic/ aluminium laminate film, fill them and seal them. This is the way many popular snack food items are packaged. Still more complete systems form the container from roll stock film, fill the container to exact weight, draw a vacuum on the package to remove oxygen, back flush the package with inert nitrogen gas, seal the package and finally stack the packages into cardboard cartons. In this way, some dessert powders and dehydrated soups are commonly packaged.

The container-forming step is not restricted to the use of paper laminates or films of various materials. Some food-packaging machines handles plastic resins in granular form followed by melting and blow-molding or otherwise forming rigid or semi rigid containers for immediate filling and sealing. Main advantages of this system are the savings of storage space for various empty containers in food plants and the in-line production of virtually sterile containers, since the heat to melt the plastic resins also kills microorganisms.