Site pages

Current course

Participants

General

Module 1. Dairy Development in India

Module 2. Engineering, thermal and chemical proper...

Module 3. Unit operation of various dairy and food...

Module 4. Working principles of equipment for rece...

Module 5. Dairy plant design and layout, compositi...

Module 6. Deterioration in products and their cont...

Module 7. Physical, chemical and biological method...

Module 8. Changes undergone by the food components...

Module 9. Plant utilities requirement.

References

Lesson 23. Physical methods of food preservation-I

23. DRYING/DEHYDRATION:

Drying or dehydration involves the removal of water from the food by controlled processes, which may be done by

-

Evaporation due to heating of the product.

-

Osmotic dehydration.

-

Sublimation, or freeze drying.

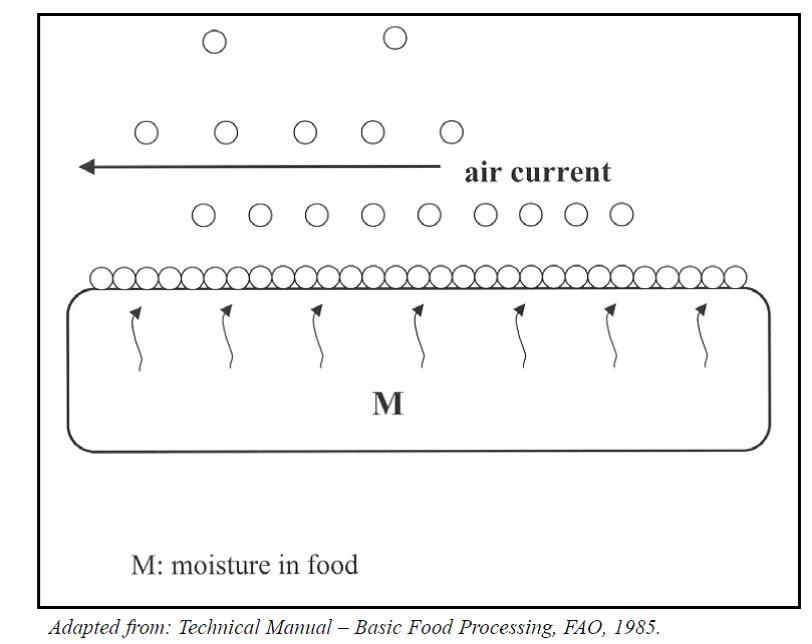

There are two distinct stages in this process.

-

In the first stage, surface water removal depends solely on the state of the air surrounding the food, such as its temperature, relative humidity and speed.

-

In the second phase of drying, the moisture within the food moves to the surface. As the air is heated, its relative humidity decreases, resulting in more absorption of water.

The rate of drying depends on the time the moisture takes to get to the surface. The heating of the air around a food product causes faster drying.

Although in case of starchy foods, the shortest drying time may be referred, to as the common change of “case hardening”. In such an event, water removal from the surface is much faster than the rate at which water migrates from the interior. The surface, therefore, dries into a hard layer, which actually prevents the migrating water from reaching the surface.

Factors on which the selection of a particular dryer/drying method depends include:

form of raw material and its properties;

desired physical form and characteristics of dried product;

necessary operating conditions;

operation costs.

Several types of dryers and drying methods, are commercially used to remove moisture from a wide variety of food products including fruit and vegetables. With this method of preservation, retains most of the flavours, giving less bulkiness to the product (reduced shipping costs) with extended shelf life.

There are five basic methods of drying which are as follows:

Tunnel Dryer

Solar Dryer

Spray Dryer

Vacuum Dryer

Freeze Drying

23.1 Tunnel Drying:

Many years ago a solar tunnel dryerwas developed at the university of Hohenheim, with the purpose of preserving agricultural products by the means of drying.

With a joint development of the Institute for Agricultural Technology in the Tropics and Subtropics at the University of Hohenheim and Innotechcompany, the solar dryers of this type are now in use in over 75 countries.

This device is employed for the hygienic preservation of foods. It forms a good alternative for seasonal agricultural surplus, deficient transport capabilities for fresh products and insufficient preservability of undried products. At the same time, the quality of goods dried in this way is substantially superior to traditional drying.

Fishermen in Bangladesh uses the solar dryer for the hygienic drying of their catch. Similarly spices are also dried in China etc.

The solar tunnel dryer is 20m long and 2m wide. It can be loaded with between 300 and 500kg of goods to be dried.

23.2 Sun Drying/Solar Drying

Sun drying and solar drying are obvious alternatives for drying due to the abundance of natural sunlight. Although the two terms are sometimes used interchangeably, sun drying refers to the removal of moisture by merely placing the commodity in the sun, e.g., on a barbecue, rack, etc. Sun drying of fruit crops is still practiced for certain fruit such as prunes, figs, apricots, grapes and dates.

The main problems for sun drying are dust, rain and cloudy weather. Therefore, drying areas should be dust-free and whenever there is a threat of a dust storm or rain, the drying trays should be stacked together and placed under cover. In order to produce dust-free and hygienically clean products, fruit and vegetable material should be dried well above ground level so that they are not contaminated by dust, insects, livestock or people. All materials should be dried on trays designed for the said purpose. The most common drying trays have wooden frames with a fitted base of nylon mosquito netting. Mesh made of woven grass can also be used. The trays should be placed on a framework at table height from the ground to allow air to circulate freely around the drying material and also to keep the food product well away from dirt. The material should be stirred/turned over at least once an hour, during the initial period which will help the material dry faster and more evenly, prevent it sticking together and improve the quality of the finished product. At night the trays should be stacked in a ventilated room or covered with canvas. Plastic sheets should NEVER be used for covering individual trays during sun drying.

Dry or nearly dry products can be blown out of the tray by the wind. However, this can be protected by covering the loaded tray with an empty one; this also gives protection against insects and birds.

Limitations of traditional sun drying include the following:

Intermittent moisture loss as it is largely dependent on the weather.

Drying rates are usually slow and do not result in high quality products.

Moisture levels are too high for prolonged storage.

Insect infestation.

Solar drying, involves capturing and concentrating solar energy for the purpose of removing water. This method has increased its popularity, although commercial solar dryers with high rates of efficiency are often quite expensive.

The advantages of solar drying over sun drying include:

Faster drying rates as higher air temperatures are generated.

Lower final moisture content of the finished product.

Greater protection of the product from rain, dust, pests.

Low insect and mould infestation due to higher temperatures.

Essentially, there are two types of solar dryers – direct and indirect. Regardless of which type is used, it is important to have information on the seasonal and daily variation of sunshine, humidity, temperature, wind speed and direction during drying. (Matthew G. Green, 2001)

Advantages of Drying:

Long Shelf Life– Most microorganisms responsible for food spoilage are unable to grow and multiply in the absence of moisture, also enzymes catalyzing the undesirable changes in foods are limited due to low moisture content, resulting into a longer shelf life of foods.

Reduced Weight– Results in reduced transportation, storage and shipping costs.

Convenience – The production of convenience items with novelty appeal for niche markets makes drying an attractive option.

Concentration of nutrients– The removal of most of the water from a food results in a highly concentrated source of nutrients.

No refrigeration is required for dried products – Savings in energy and storage costs together with the long shelf life provide a lucrative processing alternative for tropical countries.

Inexpensive - The method is simple to carry out and inexpensive, and can be easily employed by grower, farmer, cooperative, etc., as it uses the natural resource/source of heat: sunlight.

Disadvantages of Drying

Disadvantages of drying are few, and mainly relate to oxidation, which usually accompanies drying. This results in losses of micronutrients such as carotene and ascorbic acid, with minimal loss in protein as a result of browning reactions, that reduces consumer appeal. There might also be changes in flavour and texture if drying is not properly controlled, particularly with regard to maximum temperatures.

Shade drying

Shade drying is carried out for products which can lose their colour and/or turn brown if kept in direct sunlight. Products which have naturally vivid colours like herbs, green and red sweet peppers, chilies, green beans and okra give a more attractive end-product when they are dried in the shade. Under dry conditions when there is a good circulation of air, shade drying takes little more time than is normally required for drying in full sunlight.

23.3 Spray drying

The development of spray drying equipment and technique evolved over a period of several decades from the 1870s through the early 1900s. Spray drying comes from an age of World War II, with the sudden need to reduce the transport weight of foods and other materials.

This technique enables the transformation of feed from a fluid state into dried particulate form by spraying the feed into a hot drying medium. It is a continuous particle processing drying operation. The feed can be a solution, suspension, dispersion or emulsion. The dried product can be in the form of powders, granules or agglomerates depending upon the physical and chemical properties of the feed, the dryer design and final powder properties desired (Michael, 1993).

Spray drying process mainly involves five steps:

(i) Concentration: Feedstock is normally concentrated prior to introduction into the spray dryer.

(ii) Atomization: The atomization stage creates the optimum condition for evaporation to a dried product having the desired characteristics.

(iii) Droplet-air contact: In the chamber, atomized liquid is brought into contact with hot gas, resulting in the evaporation of 95%+ of the water contained in the droplets in a matter of a few seconds.

(iv) Droplet drying: Moisture evaporation takes place in two stages -1) during the first stage, there is sufficient moisture in the drop to replace the liquid evaporated at the surface and evaporation takes place at a relatively constant rate and 2) the second stage begins when there is no longer enough moisture to maintain saturated conditions at the droplet surface, causing a dried shell to form at the surface. Evaporation then depends on the diffusion of moisture through the shell, which is increasing in thickness.

(v) Separation: Cyclones, bag filters, and electrostatic precipitators may be used to purify and cool the air so that it can be released to atmosphere. Spray drying process have advantages that can be designed to virtually any capacity required. Feed rates range from a few pounds per hour to over 100 tons per hour. It can be used with both heat-resistant and heat sensitive products. Nearly spherical particles can be produced. (Keey& Pham, 1976)

23.4 Vacuum drying

Since evaporation of water takes place more readily at lower pressures, drying under vacuum is faster. This method is more expensive than air-drying and is reserved for specialized products for sublimation from frozen foods.

Although the food structure is better conserved, the equipment and its maintenance are costly. Vacuum dehydration processes are useful for low moisture / high sugar fruits like peaches, pears and apricots.

23.5 Freeze drying

Freeze-drying is a method of preservation that makes use of the physical principle known as sublimation, the process by which a solid passes directly to the gaseous phase without first melting. Freeze-drying is a desirable way of preserving food because at low temperatures (commonly around –10°C to –25°C) chemical reactions take place very slowly and pathogens have difficulty surviving. The food to be preserved by this method is first frozen and then placed into a vacuum chamber. Frozen water in the food then sublimates, leaving the moisture content in the final product of as low as 0.5%.

The steps of Freeze Drying include:

1 Freezing of the product.

2 Vacuuming– It ensures that the water does not pass through the liquid phase and goes straight to a gas.

3 Heating the product – It increases the rate of the reaction.

4 Condensation – Condenser plates move the vaporized solvent to a solid state.

Freeze drying of food products gives following advantages:

Fresh-like flavors of the products

Label friendly....all natural, no additives, preservatives or artificial flavoring

Concentrated nutritional values

Shelf stable

Enhanced texture

Vibrant color

Intense fragrance

High anti-oxidant values

Organic compatible

Superior alternative to drum and spray drying