Site pages

Current course

Participants

General

Module 1. History and types of greenhouse

Module 2.Function and features of greenhouse

Module 3.Scope and development of greenhouse techn...

Module 4.Location, planning and various components...

Module 5.Design criteria and calculations

Module 6. Construction materials and methods of co...

Module 7. Covering material and characteristics

Module 8. Solar heat transfer

Module 9. Solar fraction for greenhouse

Module 10. Steady state analysis of greenhouse

Lesson-10 Greenhouse Covering

10.1 INTRODUCTION

One of the most important parts of a greenhouse facility is the covering. Since sunlight is generally the limiting factor in wintertime greenhouse production, a covering that transmits maximum sunlight in the plant growth spectrum is essential. Physical durability and optical stability are other critical factors. Several types of covering materials are presently available. Which one is best, or most economical over the long term, is not easy to state. Glass has been the long-time standard and is still the most stable but other film and rigid plastic materials are offering lower cost coverings but with varying levels of dependability and life.

10.2 FACTORS TO BE CONSIDERED WHILE SELECTING GREENHOUSE COVERINGS

10.2.1 Performance

Plants respond best to diffused light. If you’re looking for the greenhouse covering that will give you the best, most dynamic plant growth, you should consider greenhouse covering that provides optimal light diffusion. Greenhouse coverings which provide less light diffusion increases chances for burning and can cause the greenhouse to overheat.

10.2.2 Climate

If you live in a cool climate, greenhouse insulation is very important. In order to provide good insulation, the greenhouse plastic must be twin-walled. Because of this, twin-walled Solexx and polycarbonate greenhouse covering make good materials for people concerned with both cold weather and substantial snow loads. However, if you live in a warmer climate, it is important to ensure that your greenhouse covering will not let your plants burn from intensely concentrated light. Light diffusion is crucial to preventing plant sun burn. If you are hoping to grow during the summer months, avoid single-walled or twin-walled polycarbonate, which easily overheat.

10.2.3 Appearance

For many people, the desire to see in and out of the greenhouse is important. In this case, polycarbonate greenhouse covering is the best option because it is the most transparent. It is important to note that polycarbonate does wear over time, so if you want your greenhouse to remain looking like new it needs to be washed with a soft cloth periodically and kept clear of anything that may cause scratches.

10.2.4 Longevity and Cost

Replacing a greenhouse covering can be a hassle, so it is important to choose something long-lasting. Polycarbonate, typically the most expensive greenhouse covering, has a warranty period of about ten years, depending on the manufacturer. Although it is quite long-lasting, it can be difficult to replace because polycarbonate sheets come in limited sizes and are not easily cut. Therefore, you may be unable to find polycarbonate replacement sheets suitable for your particular greenhouse. Polyfilm plastic is a common greenhouse covering for people covering large greenhouses that are only being used seasonally. Although it is relatively inexpensive, it needs replaced yearly to every few seasons and is tears easily in wind and hail.

The covering material used on a greenhouse influences the productivity and performance of a structure. It impacts on the level and quality of light available to the crop. Diffused light is better than direct light. Fluorescent and pigmented films can increase the proportion of good red light. Dust, attracted to plastic films, will reduce the transmission of radiation. Water droplets on the inside of coverings have been shown to reduce light transmission by 8% and will also block thermal radiation.

Greenhouse coverings all reduce light to some extent. As coverings become dirty and as they get older, less light enters the greenhouse. Condensation (water drops) on the covering material also reduce light. Light coloured materials in the greenhouse, such as white weed matting, increase the light available to the crop.

Key characteristics that should be considered in selecting a covering material are the cost, its durability (how long it lasts), its weight and ease of repair or replacement, how much light is transmitted through the material and how much energy moves through the material.

Diffusing materials are designed to scatter incoming light and result in better light conditions for crops e.g. a cloudy white plastic film diffuses light better than a clear plastic film.

10.3 TYPES OF GREENHOUSE COVERINGS

10.3.1 Glass

Glass has long been the traditional covering. Its favorable properties include:

High transmission in the photo synthetically active radiation (PAR) bandwidth

Good heat retention at night

Low transmission of UV light

Durability

Low maintenance costs

The biggest draw-back of glass is the initial cost, though it has been demonstrated that over a period of time (10+ years) the cost of glass compares favourably with other materials.

10.3.2 Plastic Sheeting

Essentially there are three materials in this category - polycarbonate, acrylic (polymethyl methacrylate) and fibre glass. Sheeting products are more durable than plastic films and have fairly good heat retention, good initial transmission in the PAR range and low UV light transmission.

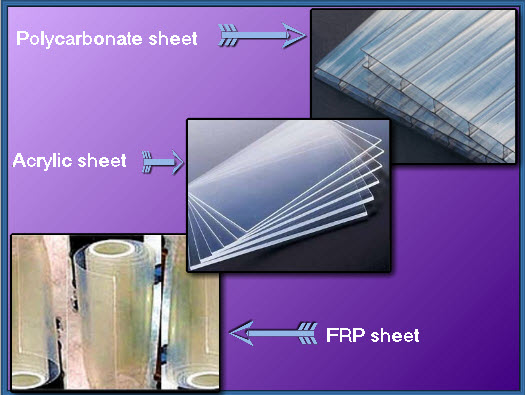

Fig 10.3.1 Plastic sheets used for greenhouse covering

(Source: www.e-tplastics.com, www.ebay.co.uk, www.gothicarchgreenhouses.com)

10.3.3 Plastic films

Films are the most common and lowest cost type of covering material. The types of film available are polythene (polyethylene), EVA (ethyl vinyl acetate) and PVC (poly vinyl chloride). With the constant improvements in plastics, these covering materials offer a lot of flexibility and performance options. Coverings can have a variety of additives which are used to give plastic films useful properties. For example, films may be used to exclude ultra violet (UV) light for chemical free pest control or reflect long wave infra- red (IR) radiation to improve heat retention at night. As a result, some plastic covering materials are coloured or tinted.

Additives to the plastic determine its;

Durability

Capacity to reduce heat loss

Capacity to reduce droplet formation

Transmission of particular wavelengths of light

Capacity to reduce the amount of dust sticking to the film.

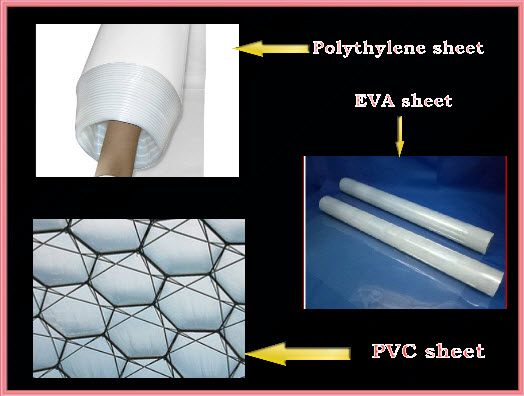

Fig 10.3.2 Plastic films

(Source: www.greenhousemegahouse.com, www.tarimasal.com, www.evafilm.org )

Types of Additives

UV (290-400 nm) absorbers and stabilizers increase durability, reduce the potential damage to biological systems in the greenhouse and may control some plant pathogens.

Infrared (700-2500 nm) absorbers reduce long wave radiation and minimize heat loss.

Long wave radiation (2500-40000 nm) absorbers reduce the loss of heat radiated from materials and objects (including plants) inside the greenhouse.

Light diffusers scatter light entering the greenhouse, reducing the risk of plants getting burnt and improving the amount of light available to the lower parts of the plant.

Surfactants reduce the surface tension of water, dispersing condensation.

Antistatic agents reduce the tendency of dust to accumulate on plastic films.

In addition,

Colour pigments may improve plant growth by altering the proportion of selected wavelength ranges.

Fluorescence may be used to increase the emission of red light.

Glossy surfaces may repel insects.

The process of making multilayer films enables thin layers of materials with different properties to be joined to make superior composite films.

Properties such as durability, creep (deformation over time) and long wave radiation absorption can be improved.

10.3.4 PROTECTIVE SCREEN FABRICS

There are a number of different materials in this category.

10.3.4.1 Shade cloth:

Reduces the amount of solar energy entering the greenhouse, which lowers plant stress

Reduces light intensity

Will protect structures from hail damage.

If shading is required, pale coloured materials should be used as these uniformly reflect solar radiation. A range of products exist that offer shading from 30% up to almost total blackout. Whitewash paints are another option that can be applied to reduce the amount of radiation entering the greenhouse.

Fig 10.3.4 Shade cloth

(Source: www.rrpolynet.com )

10.3.4.2 Solar and thermal screens:

Reduce the amount of solar radiation incident on the crop or

Prevent the escape of long wave radiation from the greenhouse and trap warm air.

The first use allows some radiation to penetrate and reflects the rest. This is used for temperature control during the day. The second type retains energy within the greenhouse and is used at night. Thermal screens are typically drawn over the crop or structure when needed.

Fig 10.3.4 Thermal screens

(Source: www.growsave.co.uk )

10.3.4.3 Insect-proof screens:

Exclude insect pests, reducing the need for chemicals.

Restricted airflow is the main disadvantage. The type of screen used will depend on the insects to be excluded, for example, thrips require the finest sized screen. Plastic screens eventually suffer from the same UV deterioration as plastic films.

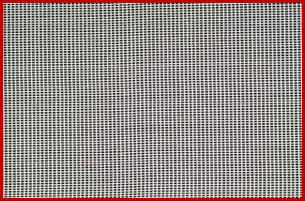

Fig 10.3.5 Insect proof screens

(Source: www.greenhousemegastore.com )

10.4 MAINTENANCE OF GREENHOUSE COVERINGS

A poorly maintained covering material can lose a lot of energy and significantly increase production costs. Glass coverings should be kept clean and broken panels should be replaced. Plastic coverings need to be replaced routinely. The performance of plastic coverings declines over time. Old coverings reduce light transmission which can restrict yield. The useful life of plastic films depends on the specifications of the plastic purchased. All plastic covering materials need to be replaced before they visibly start to break down; discoloration, for instance, is an early indication of wearing.

10.5 PROPERTIES OF THE IDEAL GREENHOUSE COVERING MATERIAL

i. It should transmit the visible light portion of the solar radiation which is utilized by plants for photosynthesis.

ii. It should absorb the small amount of UV 111 the radiation and convert a portion of it to fluoresce into visible light, useful for plants.

iii. It should reflect or absorb IR radiation which are not useful to plants and which causes greenhouse interiors to overheat.

iv. It should be of minimum cost.

v. It should have usable life of 10 to 20 years.

References:

1. www.caes.uga.edu : Greenhouse Coverings

2. www.greenhousecatalog.com : Selecting Right Greenhouse Material

3. www.dpi.nsw.gov.au : Greenhouse -covering materials

4. www.tnau.ac.in : Planning of greenhouse facility