Site pages

Current course

Participants

General

Module 1. Moisture content and its determination.

Module 2. EMC

Module 3. Drying Theory and Mechanism of drying

Module 4. Air pressure within the grain bed, Shred...

Module 6. Study of different types of dryers- perf...

Module 5. Different methods of drying including pu...

Module 7. Study of drying and dehydration of agric...

Module 8. Types and causes of spoilage in storage.

Module 9. Storage of perishable products, function...

Module 10. Calculation of refrigeration load.

Lesson 2. Determination Of Moisture Content

The moisture content is determined by several direct and indirect methods. These can be classified in different sections as shown in Figure 1.

Figure 2.1: Classification of methods of moisture determination

2.1 Direct Methods

The direct methods include mainly thermo gravimetric methods. The moisture content can be determined by an oven method directly. The food is weighed and dried, then weighed again according to standardized procedures. In the Thermogravimetric method, moisture is always separated. Thus, there is no distinction made between water and other readily volatile product components. A representative sample must be obtained to provide a useful moisture content evaluation. Also, the moisture content of the product must be maintained from the time the sample is obtained until the determination is made by storing in a sealed container. Thermogravimetric techniques can be used to continuously measure the mass of a sample as it is heated at a controlled rate. The temperature at which water evaporates depends on its molecular environment: free water normally evaporates at a lower temperature than bound water. Thus by measuring the change in the mass of a sample as it loses water during heating it is often possible to obtain an indication of the amounts of water present in different molecular environments. The figure 2 shows the process of measuring moisture content thermo gravimetrically. For many food samples this method is mandatory particularly for grains. For grains the moisture content is measured by heating the grain in hot air oven at 100-110 °C for 24 hours or until constant weight comes. For fruits and vegetables where heat sensitivity is problem, vacuum is applied in the oven to decrease the boiling point of moisture. The product temperature generally varies in vacuum oven between 60-70°C and vacuum is maintained at <450 mm Hg. The advantages and disadvantages of direct methods are given in Table 1 which can be used for selection of particular method for moisture content determination.

fig. 2.1 determination of moisture content by oven drying

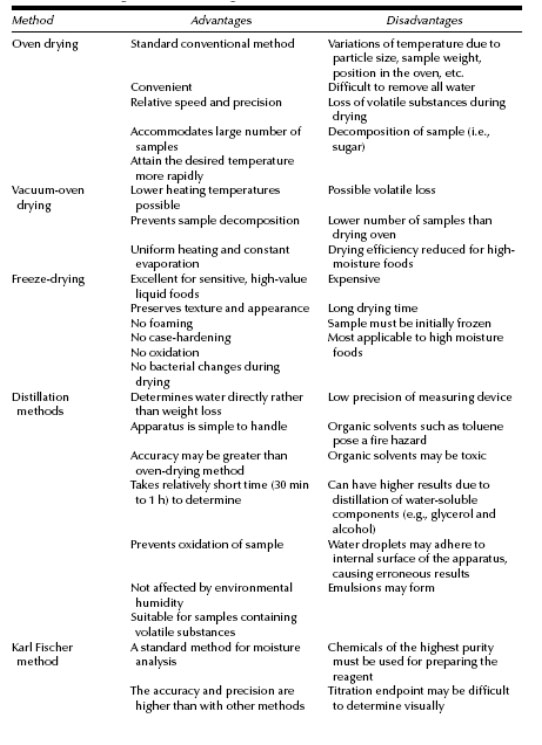

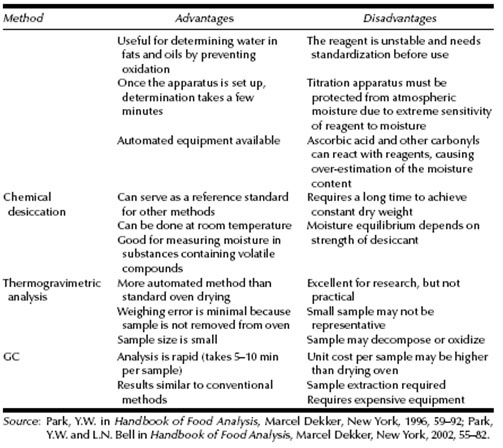

Table 1: Advantages and Disadvantages of direct Methods for Moisture

2.2 Indirect Methods

There are several methods developed to determine the moisture content rapidly. These include use of modern heating, measurement methods like infrared, microwaves, ultra sound, and spectroscopy. These methods are developed due to requirements of rapid, nondestructive and precise moisture content determination. The indirect methods are generally faster than the direct methods for moisture determination. When done properly, the indirect methods can be as accurate and precise. However, the accuracy and precision of the indirect methods depend on careful preparation and analysis of known standards to establish reliable calibration curves. Although most indirect methods require a large capital investment in equipment, the potential application for rapid on-line quality control might make the investment worthwhile. Nevertheless, preparation of the standards and accurate calibration curves must be verified by a specific direct method to establish a reliable indirect method of instrumentation that can achieve accurate and precise predicted values. One of the most important indirect methods in foods is use of moisture meters for grains. Most moisture meters measure the electrical properties of grain, which change with the moisture content. This is considered an indirect method and must be calibrated by a direct method. It is important to follow moisture meter directions carefully to achieve an accurate moisture test. A moisture meter should be periodically checked to see if it is accurate. One method of checking the meter is to compare it to at least two other meters. There are several factors that control use of each method. The advantages and disadvantages of indirect methods are given in Table 2.

Table 2: Advantages and Disadvantages of indirect Methods for Moisture Determination

2.3 Problem:

2.3 Problem:

1. Suppose, for example, that you weigh 10 g of grains (Ww) into a 4 g container and that after drying the container plus grains weighs 6.3 g. Subtracting out the 4-g. container weight leaves 2.3 g as the dry weight (Wd) of your sample. Percent moisture would be:

Mn = ((Ww-Wd)/Ww) x 100

= ((10 - 2.3) / 10) x 100

= 77%