Site pages

Current course

Participants

General

Module 1. Moisture content and its determination.

Module 2. EMC

Module 3. Drying Theory and Mechanism of drying

Module 4. Air pressure within the grain bed, Shred...

Module 6. Study of different types of dryers- perf...

Module 5. Different methods of drying including pu...

Module 7. Study of drying and dehydration of agric...

Module 8. Types and causes of spoilage in storage.

Module 9. Storage of perishable products, function...

Module 10. Calculation of refrigeration load.

Lesson 26. Control Of Environment Inside Storage

The environment, in regard to temperature and relative humidity, inside a storage structure plays and significant role as far as stability of the commodity is concerned which is of paramount importance for a processor.

26.1 Aeration

Aeration preserves the quality of stored grain by keeping an even and cool temperature, and is a valuable tool for managing grain quality at harvest and in storage. Grain stored under aeration can be held safely at a higher moisture content and retain its viability and vigour longer.

26.2 The advantages of aeration

-

Extends the harvesting window of grain and seed crops reducing delays from rain at harvest and the downgrading of premium grain due to weather damage.

-

Minimizes colour deterioration from delayed harvest of premium products that are paid on the basis of colour , such as shochu barley or pulses.

-

Equalises the silo temperature to minimise hot spots, which directly affect grain quality and provide favourable conditions for insect and mould contamination.

-

Protects high moisture grain from developing moulds in storage.

-

Cools the grain and reduces damage from insect populations in high throughput storage, typically lot feed operations, where the grain is fed to stock and there are limited opportunities for fumigation.

-

Provides opportunities to supply wheat to millers or manufacturers throughout the year. Wheat milled for Flour retains its baking qualities longer when stored cool.

26.3 The aeration process

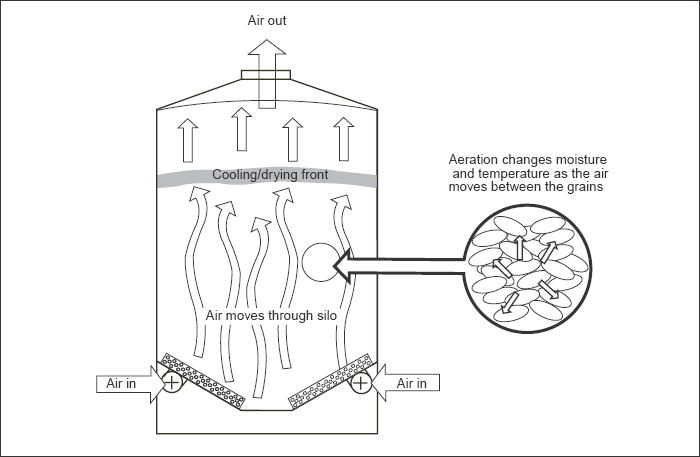

Aeration passes ambient (unheated) air through bulk grain. If the air passing through has a relative humidity (RH) that is different to the air surrounding the grain, then moisture moves either from the grain or to the grain until equilibrium is reached.

Fig. 26.1 Aeration Process

26.3.1 Long term storage of low moisture grain

Low airflow aeration

Low flow aeration protects the quality of low moisture grain for many months in storage and has the added advantage of slowing the development of insect populations. To hold low moisture grain in a safe condition for long storage, a fan capacity of about two liters per second per tonne (l/s/t) is usually adequate. Exhaust air must be able to escape freely from the top of the storage. It is recommended for an opening of at least 0.1 m2 for each 500 liters per second of air delivered to the storage. (As a guide, a hole 30 cm by 30 cm is approximately 0.1 m2). Exhaust vents must be designed to prevent water entering the silo. Temperature monitoring and automatic fan control systems are recommended for long-term storage. The controllers select the best quantity and quality of air for use in the system and some controller models prevent high humidity air entering the grain bulk.

26.3.2 Short-term storage of high moisture grain

Medium airflow aeration

Harvesting barley and other grains at high moisture levels, above those suitable for delivery and storage, optimizes quality and minimizes the risk of fungal staining and sprouting and losses due to wet harvest conditions. Medium airflow aeration is needed to preserve the quality of high moisture grain before it is dried in a heated air dryer. Under aeration, the moisture content and temperature of the grain is equalized in the stack. This has the advantage of providing a consistent feedstock for the dryer and reduces the need for frequent changes to the dryer speed and heat settings. The airflow rate depends on the grain moisture content but is typically in the 4 to 10 l/s/t range. To hold the grain in a safe condition, aim for a temperature of 20oC at a maximum moisture content of 15 per cent. When harvesting in the early morning or late evenings the moisture content of each grain may be raised by moisture on or close to the grain surface. Airflow of 4 to 10 l/s/t will remove moisture from the surface region of each grain.

26.4 Equipment for Monitoring, Management

To properly manage stored grain the operator must be able to obtain samples from the stored grain, determine moisture content, monitor grain temperatures, and keep a simple record of both grain and ambient temperatures.

A deep bin probe should be used to obtain samples at different locations to determine the moisture content, the level of fine material, and general grain conditions. A reasonably accurate moisture tester is needed. The operator must know the accuracy of the moisture tester under all conditions. Inexpensive electrical testers can give inaccurate readings under many conditions. Readings on freshly dried grain, warm or hot grain, and excessively cold grain can be inaccurate. The operator can calibrate the tester under these conditions by checking readings with the local elevator or other more accurate testers.

Thermocouple cables installed in larger bins are valuable in monitoring temperatures in storage to determine the progress of aeration. In bins without cables, thermometer probes should be used to check the temperature at different locations within the bin. This helps in monitoring the progress of the aeration and in locating trouble spots. A thermometer to measure the exhaust air temperature and one to read ambient air temperature is necessary for proper fan management. Maximum-minimum thermometers are especially helpful because they provide the operator an indication of changes in temperature with time. This equipment not only helps the operator manage the stored grain but provides information on how the aeration system works and how stored grain responds to treatment.

References:

-

Farmnote 24/02, Aeration: for preserving grain quality.

-

K.M Sahay and K.K.Singh. Unit Operations of Agricultural Processing, Vikas Publishing House Pvt Ltd.