Site pages

Current course

Participants

General

Module 1. Perspective on Soil and Water Conservation

Module 2. Pre-requisites for Soil and Water Conse...

Module 3. Design of Permanent Gully Control Struct...

Module 4. Water Storage Structures

Module 5. Trenching and Diversion Structures

Module 6. Cost Estimation

5 April - 11 April

12 April - 18 April

19 April - 25 April

26 April - 2 May

Lesson 32. Cost Estimation Examples

Computation for Material Requirement – Some Examples

Example 1: Calculate dry material required for 1 m3 cement concrete (CC) having density of 2.3 ton/m3 with 1:3:6 ratio.

Solution:

Ratio: 1:3:6 (cement: sand: 20 mm aggregate)

Sum = 1+3+6 = 10

From Table 31.1 (lesson 31), dry matter required for 1.0 m3 CC mix is 1.54 m3

Cement requirement =![]() = 0.15 m3= 216 kg (using Table 32.1 below)= 4.3 bags of 50 kg each

= 0.15 m3= 216 kg (using Table 32.1 below)= 4.3 bags of 50 kg each

Sand requirement = = 0.46 m3 = 1.22 ton

Aggregates = = 0.92 m3 = 1.56 ton (20 mm aggregates)

Table 32.1. Bulk density of different construction material

|

Material |

Bulk Density (kg/m3) |

|

1440 |

|

1600 |

|

1700 |

|

1950 |

|

2700 |

|

2650 |

|

2160 |

Example 2: Find dry matter for 1.0 m3 brick masonry with cement and sand mortar of 1:6 ratio.

Solution:

For 1.0 m3 brick work, 500 bricks are needed (from Table 31.1 described in lesson 31).

Cement: sand ratio = 1(cement):5(sand)

Sum = 1+5 = 6

For 1 m3 brick masonry, 0.3m3 cement mortar is required (see material requirement Table in lesson 31.1).Cement requirement = 0.05 m3 and

Sand requirement =  0.25 m3

0.25 m3

Some Example of Rate Analysis

Example 3: Determine unit cost for Gabion works

Solution:

The gabion work involves collection of stones (225 mm) and their arrangement in wire mesh accordingly. The material requires are GI wire mesh and stones. Labours (unskilled and semi-skilled) worker are required for netting the wire mesh. The unit cost is computed as per the following analysis.

|

Particulars |

Quantity |

Rate (Rs/unit) |

Amount (Rs) |

|

Material |

|

|

|

|

18.2 kg |

60 |

1092 |

|

3.75 m3 |

200 |

750 |

|

Total material cost |

1842 |

||

|

Labour |

|

|

|

|

no |

240 |

120 |

|

no |

220 |

275 |

|

180 |

405 |

|

|

Total labour cost |

800 |

||

|

Total material and labour cost |

2642 |

||

|

Add 3% contingency |

79.26(say 80) |

||

|

Grand total for 3 m3 |

2722 |

||

|

Cost per m3 |

907.33(say 910) |

||

Example 4: Determine unit cost for logwood crib structures filled with stones.

Solution:

The logwood crib structures involve placement of stone (250 mm or more) in between the wooden pole to provide a barrier to flowing water. The required materials are wooden logs, nails, oils for painting, stones whereas labour requirement include skilled labour such as Carpenter, Mason, Painter and unskilled labour. The unit cost is computed as per the following analysis of rate for 15 m3 crib for span of 10 m.

|

Particulars |

Quantity |

Rate (Rs./unit) |

Amount (Rs.) |

|

Material |

|

|

|

|

|

|

|

|

22 poles |

120 |

2,640 |

|

30 poles |

140 |

4,200 |

|

20 kg |

60 |

1,200 |

|

5 lit |

40 |

200 |

|

|

|

|

|

5 lit |

30 |

150 |

|

15m3 |

200 |

3,000 |

|

Lumpsum |

|

1,000 |

|

Total material cost |

12,390 |

||

|

Labour |

|

|

|

|

10 nos. |

240 |

2,400 |

|

5 nos. |

240 |

1,200 |

|

2 nos. |

240 |

480 |

|

20 nos. |

180 |

3,600 |

|

Total labour cost |

7.680 |

||

|

Total labour and material cost |

20,070 |

||

|

Add 3% contingency |

602 |

||

|

Grand total for 15 m3 |

20672 |

||

|

Cost per m3 |

1378 (say 1380) |

||

Example 5: Determine unit cost for RCC work

Solution:

RCC work includes steel reinforcement of cement concrete. The most adopted cement concrete is of 1:2:4 mix of cement, sand and aggregates (volume basis). The density of concrete depends on the nature of aggregates used. Most frequently, 20mm stone ballast are used as aggregates. Reinforcement is done using steel bars. In watershed structures 12 mm steel bars are used. The unit cost can be computed as per the following analysis of rates.

Dry mortar required for 1m3 cement concrete = 1.54 m3.

Thus for 10 m3 cement concrete, dry mortar volume will be 15.4 m3

Cement requirement = 15.4/7 = 2.2 m3 = 64 bags of 50kg each

Sand requirement = 4.4 m3 and

Aggregates requirement = 8.8 m3

Assuming density of concrete as 2300 kg/m3, the weight of 10 m3 such concrete will be = 23 ton

|

Particulars |

Quantity |

Rate (Rs/unit) |

Amount(Rs) |

|

Material |

|

|

|

|

Cement grade 53 |

64 bags |

280 |

17,920 |

|

Coarse sand (1-2 mm) |

4.4 m3 |

2000 |

8,800 |

|

Stone ballast 20mm |

8.8 m3 |

1200 |

10,560 |

|

Mild steel bar @1% reinforcement |

0.23 ton |

60000 |

13,800 |

|

Binding wires (1 mm) |

2 kg |

65 |

130 |

|

Total material cost |

51,210 |

||

|

Labour |

|

|

|

|

Head mason (Raj mistri) |

1 |

270 |

270 |

|

Mason (mistri) |

3 |

240 |

720 |

|

Unskilled labour (beldar) |

12 |

180 |

2160 |

|

Bhisti |

6 |

220 |

1320 |

|

Sundries, T&P etc |

Lumpsum |

|

1000 |

|

Total cost of labour |

5,470 |

||

|

Centering and shuttering |

|

|

|

|

Timber planks and post |

On hire |

|

1,000 |

|

Carpenter |

6 nos |

240 |

1,440 |

|

Unskilled labour (beldar) |

1 |

|

|

|

Nails |

Lumpsum |

|

500 |

|

T&P |

Lumpsum |

|

1,000 |

|

Sub-Total |

3,940 |

||

|

Total of material and labour cost |

60,620 |

||

|

Add 3% contingency |

1820 |

||

|

Total cost for 10 m3 RCC |

62,440 |

||

|

Cost of per m3 RCC |

6,244 (say 6,250) |

||

Example 6: Determine unit cost for I-class brick work with 1:6 cement mortar

Solution:

First estimate cost for 10 m3 brick work in order to rationalize the labour requirement and mortar mix.

Dry matter requirement for mortar in brick work = 0.3m3 per m3 of brickwork. Thus 3.0m3 dry matter will be required for 10m3 brick work.

Cement requirement = (1/7)*3 = 0.43 m3 or 12.47 (say 13) bags of 50 kg each.

Sand requirement = (6/7)*3 = 2.58 m3

The unit cost can be computed as per the following analysis of rates.

|

Particulars |

Quantity |

Rate (Rs/unit) |

Amount(Rs) |

|

Material |

|

|

|

|

Cement grade 53 |

13 bags |

280 |

3,640 |

|

Coarse sand (1-2 mm) |

2.58 m3 |

2000 |

5,160 |

|

Class-I brick @500 per m3 |

5000 |

4.50 |

22,500 |

|

Total material cost |

31,300 |

||

|

Labour |

|

|

|

|

Head mason (Raj mistri) |

1 |

270 |

270 |

|

Mason (mistri) |

10 |

240 |

2,400 |

|

Unskilled labour (beldar) |

7 |

180 |

1,260 |

|

Bhisti |

2 |

220 |

440 |

|

Sundries, T&P etc. |

Lumpsum |

|

1,000 |

|

Total cost of labour |

5,370 |

||

|

Total of material and labour cost |

36,670 |

||

|

Add 3% contingency |

1,100 |

||

|

Total cost for 10 m3 RCC |

37,770 |

||

|

Cost of per m3 RCC |

3,777 (say 3,800) |

||

Estimating and costing of some watershed management work - Examples

Example 7:

Estimate the cost to construct CCT in hard soil in 20 ha area. The distance between two row of CCT is kept as 25 m and width and depth of CCT is 50 cm each.

Solution:

The construction of CCT involves excavation only and so only labour is required with some T&P.

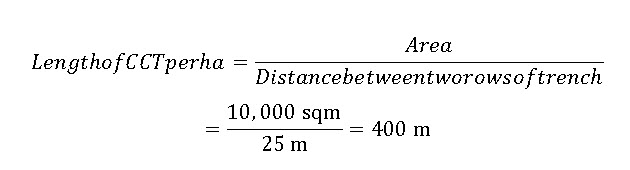

Length of CCT per ha can be calculated using following equation

Earthwork volume = 0.5*0.5*400 = 100 m3

|

Particulars |

Quantity |

Rate (Rs/unit) |

Amount(Rs) |

|

Labour |

|

|

|

|

Unskilled labour @1.5 m3 per manday |

67 mandays |

180 |

12,060 |

|

Skilled labour |

2 mandays |

240 |

480 |

|

T&P |

Lumpsum |

- |

500 |

|

Total labour cost |

13,040 |

||

|

Per m3 earth work |

130 |

||

Example 8:

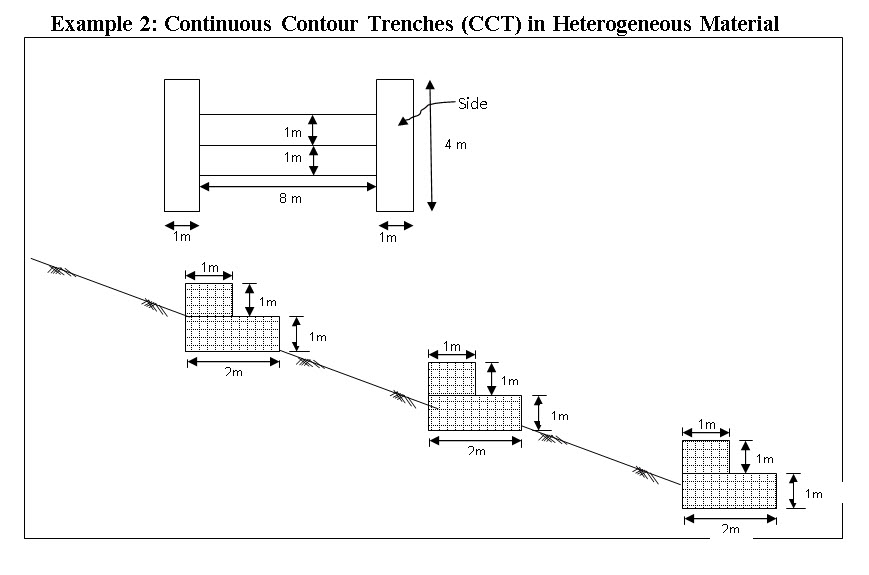

Gabion structures are proposed to stabilized 240 m long and 8 m wide gully. The average slope of the gully bed is 10% and the vertical interval may be taken as 2 meter. The proposed design is presented in Fig. 32.1. Estimate the project cost.

Example 2: Continuous Contour Trenches (CCT) in Heterogeneous Material

Department of Agriculture in Gaya District, Bihar proposes to make CCT in a catchment area of 40 hectares. The top soft soil stratum has a depth of 30 cm followed by hard soil for about 1 metre. The horizontal spacing between two successive rows CCT is 25 m. The width and depth of the CCT is 50 cm x 50 cm. Calculate the cost of construction of CCT.

Solution:

Fig. 32.1 Proposed design of gabion

Solution: Since the vertical interval is 2 meter and 10% slope, means gabion should be 20 m apart horizontally. Thus total number of gabion for the gully stabilization would be 240/20 = 12. The average gully width is 8 meter and 1 meter wide side wall is to be provided, the total width for earth work would be 8+2 =10m. The estimate involves computation of material and abstract of cost.

- Details of measurement and quantities

|

Sl. No. |

Particulars of work/items |

No |

Length (m) |

Width (m) |

Height (m) |

Quantity (m3) |

|

1 |

Excavation in foundation |

12 |

10 |

2 |

0.6 |

144 |

|

2 |

Gabion box filled with boulders of >200mm |

|

|

|

|

|

|

|

|

12 |

10 |

2 |

1 |

240 |

|

|

|

12 |

10 |

1 |

1 |

120 |

|

|

|

12 |

4x2 (two sides per gabion) = 8 |

1 |

1 |

96 |

|

Total gabion work |

456 |

|||||

- Abstract of cost

|

Sl. No. |

Particular of work/ items |

Quantity |

Unit |

Rate (Rs/Unit) |

Amount (Rs) |

|

1 |

Excavation in foundation |

144 |

m3 |

130(see example 7) |

18,720 |

|

2 |

Gabion work |

456 |

m3 |

910(see example 3) |

414,960 |

|

Total cost |

433,680 |

||||

References

Dutta, B.N. (1966). Estimating and Costing for Civil Engineering, Lucknow

Khanna, P.N. (1996). Indian Practical Civil Engineers’ Handbook

New Delhi: Engineers’ Publishers

Watershed Works Manual. (2007). Ministry of Rural Development, Government of India, pp.226-273.

Mohan, S. C. et al. (2007). Training Manual on Soil Conservation & Watershed Management, pp. 380-393

Sharda, V.N., Juyal, G.P., Prakash Chandra and Joshi, B.P. (2007). Training Manual – Soil Conservation and Watershed Management (Vol II Soil and Water Conservation Engineering). CSWCRTI, 218, Kaulagarh Road, Dehradun.