Site pages

Current course

Participants

General

22 February - 28 February

1 March - 7 March

8 March - 14 March

15 March - 21 March

22 March - 28 March

29 March - 4 April

5 April - 11 April

12 April - 18 April

19 April - 25 April

26 April - 2 May

Lesson 9. Study of mould board plough: accessories, adjustments, operation and material of construction

ADJUSTMENTS OF MOULD BOARD PLOUGH

For proper penetration and efficient work by the mould board plow some clearance is provided in the plow. This clearance is called suction. These are of two types:

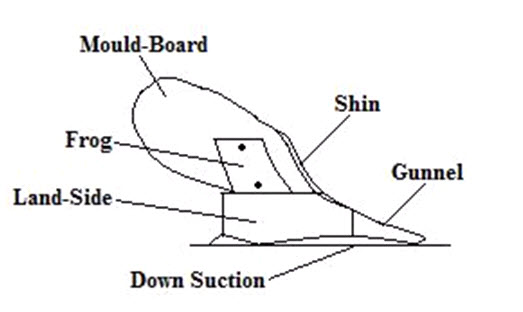

1) Vertical Suction: It is the vertical distance from the ground, measured at the joining point of share and landslide. It helps the plow to penetrate into the soil to a proper dept. It is generally 3 to 5 mm.

2) Horizontal Suction: Maximum clearance between the landslide and horizontal plane touching point of share at its gunnels side and heel of landslide. It helps the plow to cut the proper width of furrow slice. It is generally 5-13 mm.

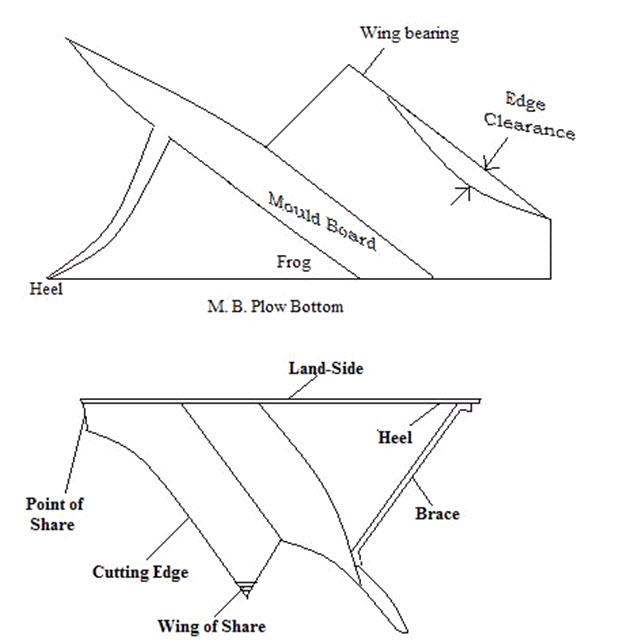

3) Angle of cutting edge from direction of travel it is 40-45 degrees.

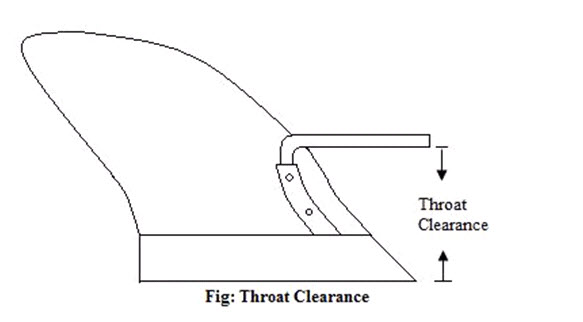

4) Throat clearance: Perpendicular distance between point of share and lower position of beam of plow.

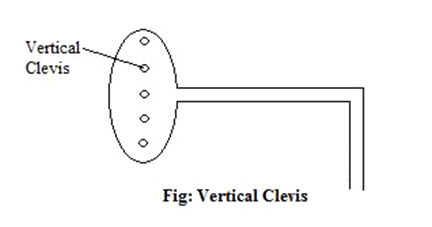

5) Vertical Clevis: It is a vertical plate with a number of holes at the end of the beam to control the depth and adjust the line of pull.

6) Horizontal Clevis: It is a device to effect lateral adjustment of plow relative to line of draft.

7) Plow Size: Perpendicular distance from wing of share to the line joining the point of share and heel of landslide. The size of mould board is expressed by width of cut of soil. Common size of tractor drawn mould board is 30 cm, 35 cm, and 40 cm. Animal drawn mould boards are of 13 to 20 cm.

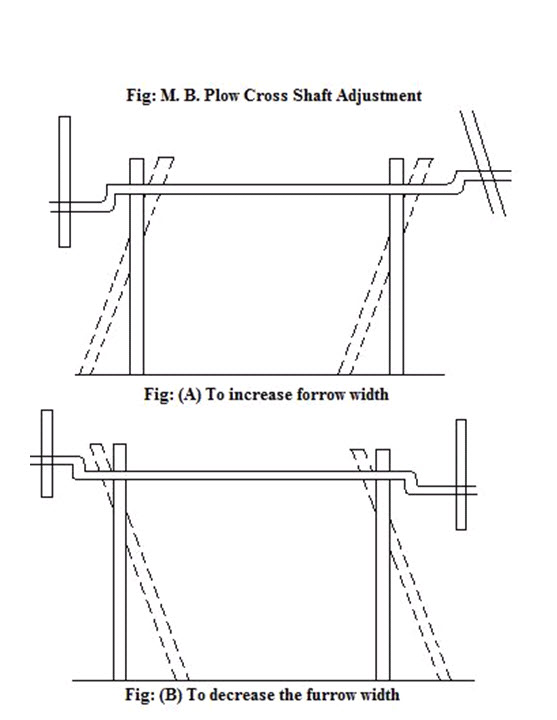

8) Mould Board plow cross shaft: It is used to make proper width adjustment of plow.

9) For tractor drawn plows:

Coulter adjustments:

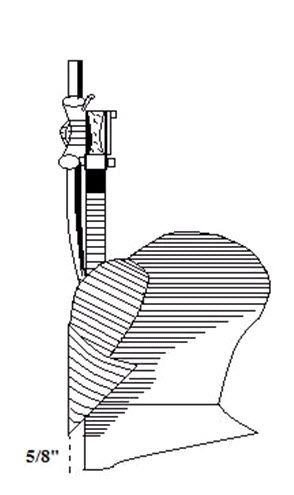

Vertical adjustments = ½ of depth or 50 mm

Horizontal adjustments = 20 mm outside the landslide.

Coulter diameter = 30 to 45 cm.

Jointer adjustments:

Depth = 4 to 5 cm

Furrow wheel adjustments: 6 to 12.5 mm clearance between rear of landslide back plow bottom and furrow wall.

REACTION OF SOIL TO MOULD BOARD: Wide range of soil conditions encountered in tillage materially affects the reactions of the soil on mould board surfaces.

1) Hard cemented soil: These soils break into large irregular blocks ahead of the plow, with no definite pattern to soil reactions.

2) Heavy sod: Due to heavy mass of roots normal share planes not observed. Normal reactions occur below the sod.

3) Packed or cemented surface: With relatively loose soil below the compacted surface. Blocks of surface layer are broken loose irregularly and lifted like boards.

4) Push Sell: Acts like freshly plowed soil. Adhesion of soil to mould board builds up pressure ahead of plow bottom. Tendencies of soil to push to one side rather than turned or lift.

5) Normal Soil Conditions: These are settled soils with a firm condition and have adequate moisture content for good plowing.

Under normal soil conditions the movement of soil on the mould board is due to the resistance of the soil ahead of the plow bottom and average speed of movement of soil across the mould board is approximately that of plow forward speed.

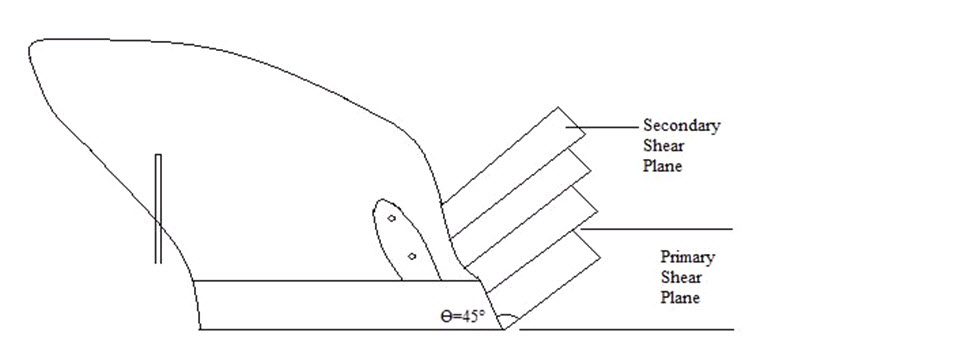

PULVERIZING ACTION: As a plow moves forward its double wedging action exerts pressure both upward and toward the open furrow. Stresses set up by this action cause soil blocks to be shared loose at regular intervals on parallel inclined share plane. These primary share planes extend forward from plow point at an angle of 45 degree in both horizontal and vertical planes retaining their relative positions as they move across the mould board surface. Soil blocks formed by primary shearing action break down as they move mould board forming secondary share planes at right angles to primary share planes.

TURNING AND INVERSION:

Lifting of furrow slice at the shine side starts earlier than wing side. Turning and inversion starts immediately. Most turning and inversion is affected by the upper part of mould board. Finally pushing and throwing the soil into the adjoining furrow. Amount of throw depends on forward speed and direction of release of soil.

SCOURING: Movement of soil across a tool surface without sticking is called scouring. Best scouring is achieved when soil-metal friction is low than that of soil-soil friction, the angle of approach of tool, soil cohesion and soil adhesion.

Scouring will occur as long as the frictional resistance at the soil-tool interface is less than the resistance at a parallel soil-soil interface. When scouring is adequate, soil flows over the tool along a patch that is determined by the shape of the tool. In non-scouring condition soil flows over a layer of soil attached to the tool surface, usually resulting in increased draft and poor performance.

In practice the soil-metal friction angle is less than the angle of soil shearing resistance. Therefore, an increase in pressure against the mould board will increase soil shearing resistance more than the soil metal frictional resistance and will improve scouring. Non-scouring is likely to occur at low spots or other irregularities, in areas of abrupt change in surface direction and in other low pressure areas.

Adhesion may be reduced by employing material that resists wetting. A slat mould board scours better than a soil mould board because the smaller contact area results in reduced adhesive forces and increased soil pressure.

Teflon is a non-wetting plastic that is being used to make a mould board plow scour in push-type non-abrasive soils. (Test conducted at various countries show that a mould board coated with a Teflon gives 23% less draft at 5.6 km)

Another approach to reduce soil-metal friction and improving scouring is by applying air to the soil-engaging surface to provide an air cushion or boundary layer which separates the two surfaces that are moving relative to each other. Air from a compressor driven by the tractor is delivered to a plenum chamber on the back side of the mould board and passes through a network of small holes to the front of the mould board. Another method is employing a moving surface to transport the soil (belt type mould board). Also mould board is coated with plaster of Paris or enameling.

BEAM-OVERLOAD PROTECTION:

Wide acceptance of mounted and semi-mounted plows need for individual overload protection devices for plow standards (Beam). For increased forward speeds these devices are needed. Spring-trip devices load against share exceeds trip release and permits plow bottom to swing rearward about horizontal, transverse axis. Unless the obstruction will permit share point to move downward entire implement is raised by tripped bottom. In hydraulic reset overload devices, hydraulic cylinders are provided.

EXPRESSING MOULD BOARD SHAPES:

Some means of identifying mould board shape is needed in comparing and analyzing the performance of different plow bottoms and for manufacturing purposes. The shapes can be expressed either mathematically or by identifying empirical methods. Plow bottoms had surfaces that could be fitted by equations representing cylindrical, hyperbolic, spiral paraboloids.