Site pages

Current course

Participants

General

22 February - 28 February

1 March - 7 March

8 March - 14 March

15 March - 21 March

22 March - 28 March

29 March - 4 April

5 April - 11 April

12 April - 18 April

19 April - 25 April

26 April - 2 May

Lesson 11. Sub-soiler and chisel plough: types, working and construction

Chisel Plow & Subsoiler

Soil has three layers as follows:

Top Layer

Hard pan 3 to 4” (Chisel plow is used)

Sub Soil (Sub soiler is used)

To break through and shatter compacted or impermeable soil layers and to improve rainfall penetration (infiltration).

Best results achieved when soil is dry.

Sub-soilers have one or two heavy standards, but chisel ploughs have a series of standards spaced at 30 cm (12”) apart and equipped with replaceable narrow shovels or teeth.

Maximum depth 45 to 75 cm for chisel plow.

Chisel plow standards may be rigidly mounted or spring cushioned or may have spring tips.

Chisel plows are operated at depth below the normal plowing zone. If any imperious layer that may be present is thin up to 18” to 30”.

Chisel plows are also employed in place of M.B. plow where inverting of the soil is not required.

As chisel plow does not pulverize the soil as much as M.B. plow, several operations are required after chiseling.

The shanks of chisel plow are made of nickel alloy and heat treated spring steel. This can also be used for doing a number of jobs by mounting different types of tynes.

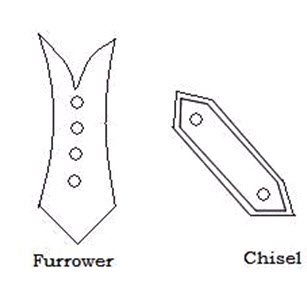

Drill shoe is used for sowing purposes, furrower and sweep for Intercultural.

Sub-Soiler: It has one or two heavy standards. It breaks the sub-soil, so that the water may penetrate into the open space and can be stored. It is a tool that breaks the ground at depth of 20” to 36”.

-

It does not pulverize the soil.

-

It is heavier than chisel plow. Since depth of penetration is more so 60-85 HP is required to pull one single standard.

-

For shallow depth we can have 2 or 3 shanks.

-

It can also be used for making tunnel to serve as drainage channel.

-

The standard of sub-soiler is usually long and narrow with heavy wedge like point.

-

The draft requirement in this case is 70-110 lb per inch.

-

Depth of operation for light and medium soil:-

(i) For heavy soil like clay loam it is 100 – 160 lbs/inch depth.

-

The standard is a main part of the implement. The projection in front is called foot. The point is replaceable and made of steel.

Effect of shape upon soil forces

Lift angle and slope of standard have effect on depth and vertical soil force.

Lift Angle: Angle between face of tool and the horizontal plane.

-

Shattering requires less effort when tool exerts upward shearing force rather than longitudinal compressive force.

-

Draft decreases when lift angle is reduced to 200 or less. At 500 lift angle compacted soil stucks to the tip of the tool.

-

200 slope of standard (bottom and handle are attached, also known as shank) are good from stand point of low draft and large downward vertical force ‘V’. But such design requires a large standard and excessive forward projection of the standard.

-

Curved standard reduces the draft by about 28%.

-

By tilting straight backward standard to 150 reduces draft by 12%.

Effect of depth and speed upon draft of chisel-type implement

Effect of depth is influenced by tool shape, orientation, soil type and soil condition.

Tool surface area, depth and soil condition influence the magnitude of speed for chisel-type implement.

In some cases a linear relation between draft and speed can be assumed over a limited range of speeds.

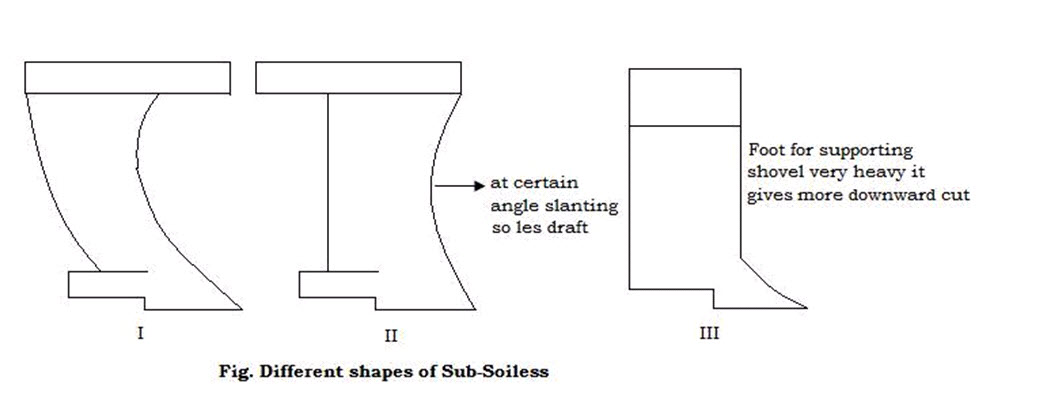

Different shapes of sub soilers:

Spelling of less draft in II and sub-soilers in caption of figure?

I & II need 25% less pull because of shape of shank.

I is of curved type which is replaceable if it breaks.

II is at certain angle slanting, draft requirement is less.

III foot for supporting shovel.They are very heavy so we operate it at a distance of spacing 4-5 ft. It gives downward cut.