Site pages

Current course

Participants

General

22 February - 28 February

1 March - 7 March

8 March - 14 March

15 March - 21 March

22 March - 28 March

29 March - 4 April

5 April - 11 April

12 April - 18 April

19 April - 25 April

26 April - 2 May

Lesson 14. Construction and working of Disc harrows,Spike-tooth and spring-tine harrows

Care and Maintenance of Disc Harrow:

1) Bearings must be thoroughly greased at regular intervals

2) All nuts and bolts must be checked daily before taking the implement to the field

3) Blunt edges of the discs should be sharpened regularly

4) During slack season, the worn parts including bearings should be fully replaced

It is better to coat the outer and inner surfaces of the discs when the harrow is lying without use in slack season

Animal Drawn Disc Harrow:

Disc harrow is used for breaking clods while preparing seed-beds. It has 6 to 8 discs fixed in two gangs. It has strong frame made of mild steel on which gangs with discs are mounted. An operator’s seat is also provided on frame. Transport wheels are fitted for easy movement of harrow from place to place. Its weight varies between 80- 100 kg.

Parts:

Disc: it is the main part of harrow which cuts and pulverizes the soil. Discs are arranged in two gangs. Thickness of material used for disc is at least 3.15 mm. the cutting edge is bevelled for easy penetration. The disc has square opening in the centre to allow the passage of the axle. Discs are made of steel with carbon content 0.80%- 0.90%.

Gang Frame: all the gangs are mounted on the frame, called gang frame. It is usually made of sturdy mild steel structure. The gang frame is bolted to the beam of the implement.

Beam: it is that part of the harrow which connects the implement with yoke. The rear end of the beam has clevis to fix its height of hitching to suit the size of the animals. It is made of wood which is locally available in the area.

Gang Angle Mechanism: it is the angle by which gang angles are adjusted. Arrangement is there for adjusting the width and depth of cut of the implement. It is done by gang angle mechanism. The lever of the gang angle mechanism is made of mild steel flat with a wooden handle. The gang angle can be adjusted between 0° to 27°

Scraper: it is the part of harrow which scrapes the soil from the concave side of the disc and keeps it clean for effective working of the harrow in the field.

Spacer (Spool): spacer is used to separate the two adjacent discs and keep them in position. It is usually made of cast iron. The spacer has a suitable square opening in the middle to allow the passage of the axle.

Clevis: clevis is the part fitted to the beam and the frame which permits vertical hitch of the harrow.

Axle: axle is usually 20x20 mm square section. The length of axle depends upon the size of the harrow.

Middle Tyne: the tyne which breaks the unbroken lstrip of soil left between two gangs of the harrow during operation is called middle tyne. This tyne is suitably fixed to the rear end of the gang frame in such a way that it is replaced easily.

Bearing: There are one or two bearings either of cast iron or wood fixed at each end of the gang.

Other Harrows:

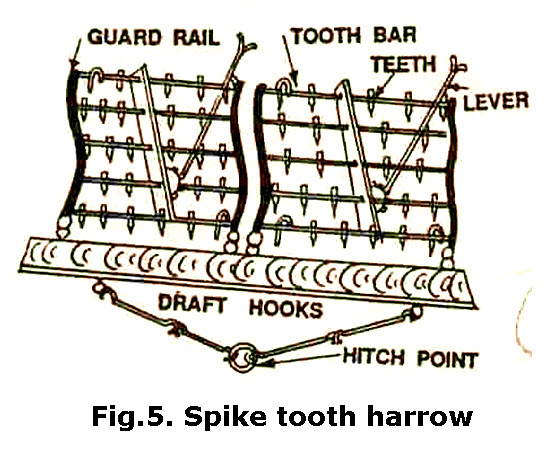

Spike Tooth Harrow or Straight tine harrow:

It is a harrow with pegs shaped teeth of diamond cross section to a rectangular frame as working part fitted in a rigid articulated or flexible frame. It is used

to break the clods,

stir the soil,

uproot the weeds,

level the ground,

break the soil and cover the seeds.

The peg shaped teeth of diamond cross- section is attached in a rectangular frame. Principal used is to smoothen and level the soil directly after ploughing. Spike tooth harrows are of two types:

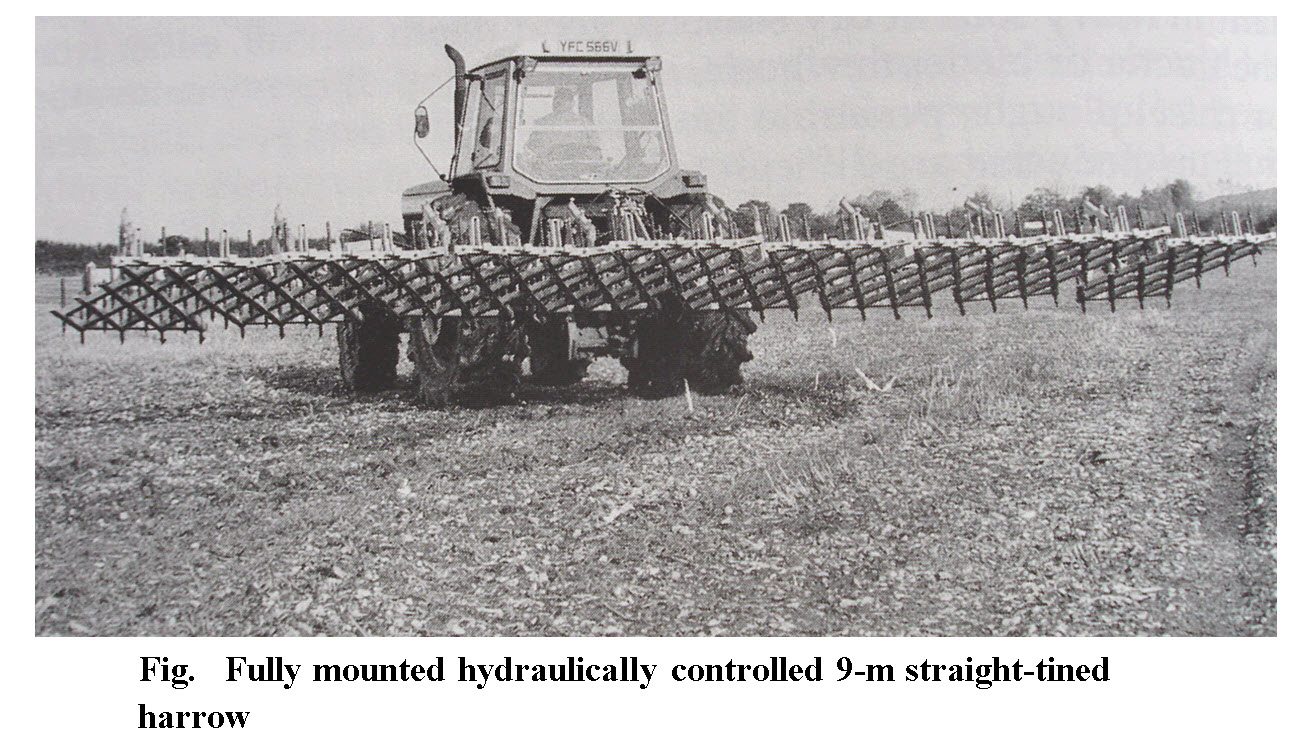

i) Rigid Tyne: The animal drawn spike tooth harrows are usually of rigid type. There may or may not be provision for changing the angles of spikes in operating condition.

ii) Flexible Type: Tractor drawn harrows are usually flexible type. It has got advantage of being rolled up for transporting purpose.

This harrow consists of:

1) Teeth: may be square, triangular or circular in section.

2) Tooth Bar: The teeth are so placed on tooth bar that one tooth is behind the other. Tooth bars are made of wood or steel. Steel bars may be round flat or channel shaped.

3) Clamps: used to fasten teeth to the tooth bars tightly so as not to be loose while in operation.

4) Guard:

5) Braces:

6) Lever:

7) Hooks:

The harrow is an excellent tool for pre-emergence cultivation to break the rain-firmed crust and small weeds. It generally works about 2 inches of depth. Spike tooth harrows may be of rigid type and flexible type. The animal drawn spike tooth harrow is usually of rigid type. These may or may not have provisions for changing the angle of spikes in operating conditions. Tractor drawn harrows are usually flexible type. It has got the advantage of being turned up for transporting purpose. This harrow mainly consists of teeth, tooth bar frame, clamps, guard, braces, levers and hooks. The teeth are made up of hardened steel with square/triangular/circular in section. The teeth are so placed on tooth bar that no tooth is directly behind the other. Teeth are fastened rigidly to the tooth bar. Clamps are rigidly fixed so as not to be loose while in operation.

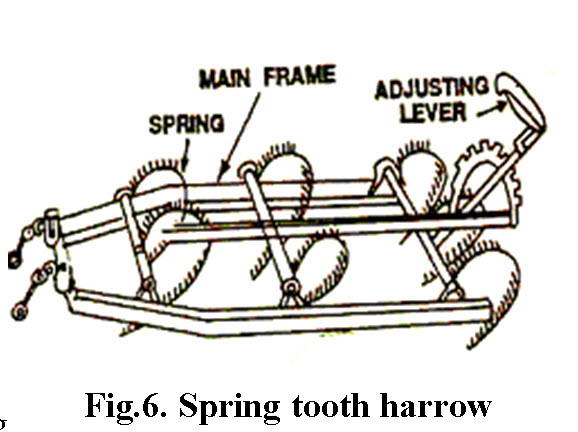

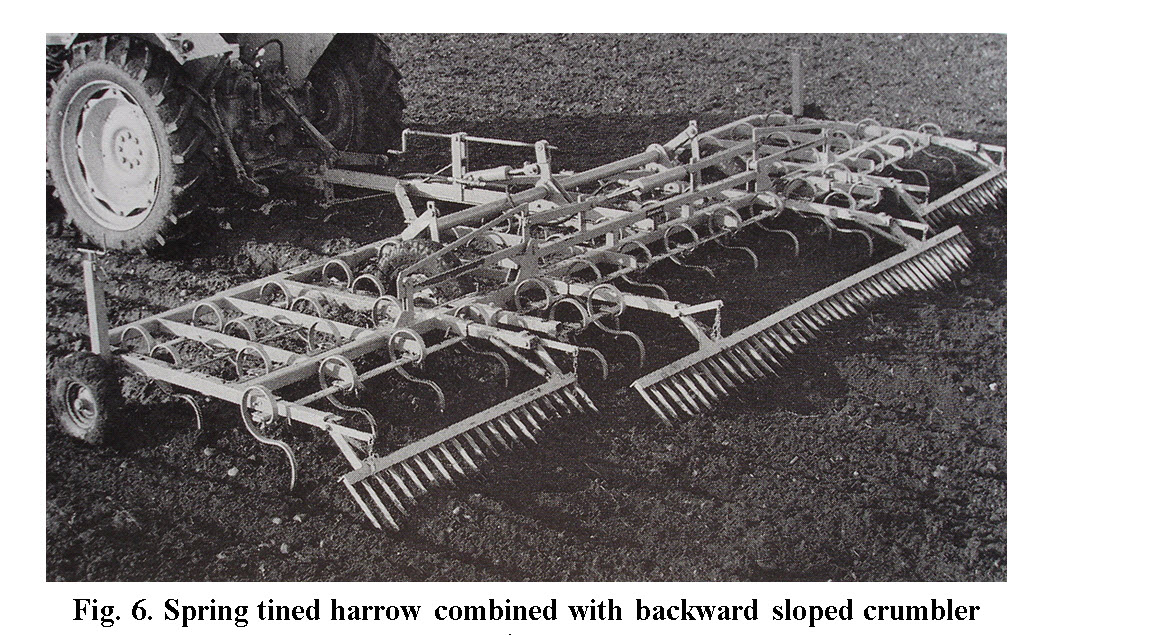

Spring tooth harrow: It is a harrow with tough flexible teeth, suitable to work in hard and stony soils. Spring tooth harrow is fitted with springs having loops of elliptical shape. It gives a spring action in working condition. It is used in the soil when obstruction like stone, roots and weeds are hidden below the ground surface. This pulverizes the soil and helps in killing weeds. This type of harrow mainly consists of teeth, tooth bar, clamps, frame, lever and links. Usually the teeth are made of spring steel. Sometimes reversible points are provided so that one end may be used after the other end is worn out. The teeth are fastened to the tooth bar by means of tooth clamps. They are provided to give rigidity and support to the harrow. The levers are provided for setting the teeth for varying the depth of harrowing (Fig.6). For light harrowing, the adjustment is done in slanting position. Draft hooks are there on each corner of every

like stone, roots and weeds are hidden below the ground surface. This pulverizes the soil and helps in killing weeds. This type of harrow mainly consists of teeth, tooth bar, clamps, frame, lever and links. Usually the teeth are made of spring steel. Sometimes reversible points are provided so that one end may be used after the other end is worn out. The teeth are fastened to the tooth bar by means of tooth clamps. They are provided to give rigidity and support to the harrow. The levers are provided for setting the teeth for varying the depth of harrowing (Fig.6). For light harrowing, the adjustment is done in slanting position. Draft hooks are there on each corner of every

section for hitching purpose. The depth of ploughing is 7 inches.

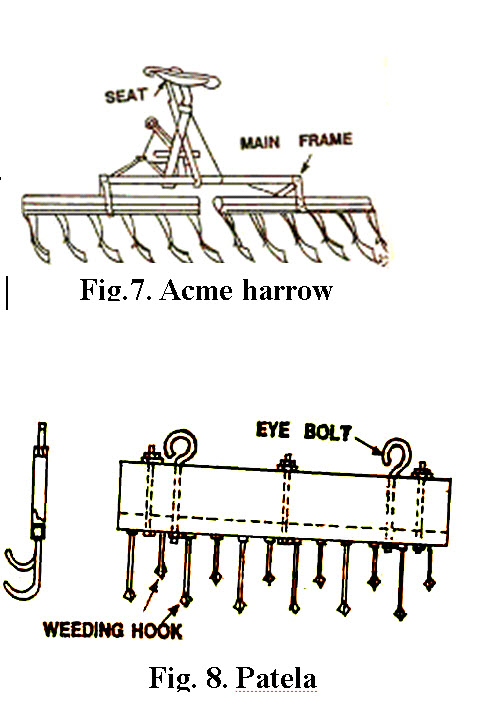

Acme harrow: It is a special type of harrow having curved knives. It is also called as knife harrow. The front part of the knife breaks the soil and crushes the clods (Fig.7). This harrow obtains a good pulverization. It is good for mulching also.

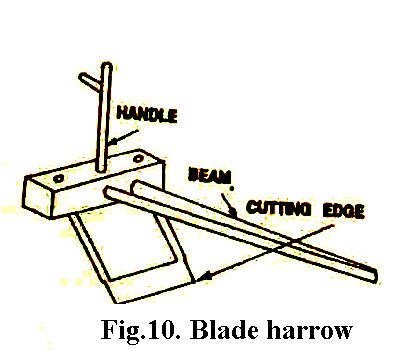

Patela It is a wooden plank used for smoothening the soil and crushing the weeds. It is also used for breaking clods, packing and leveling the ploughed soil and to remove the weeds. It is made of a wooden plank with a number of curved steel hooks bolted to a steel angle section, which is fixed or hinged to the rear side of the plank (Fig.8). The cutting edge levels and packs the soil and the curved hooks uproot and collect the weeds.

Triangular harrow It is a spike tooth harrow with triangular frame (Fig.9). The frame is made of wood and pointed spikes are fitted in the frame. The teeth of the spikes are fixed and not adjustable.

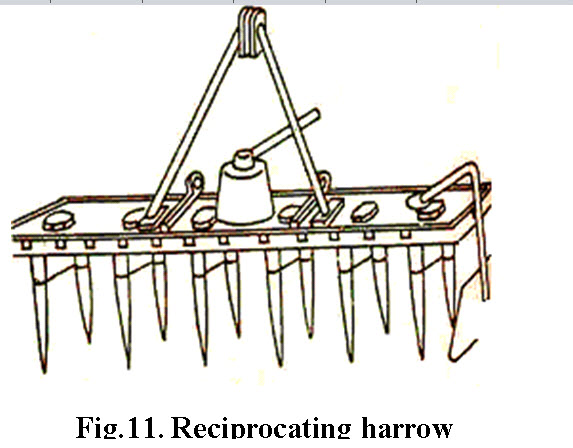

Blade harrow It is an implement, which consists of one or more blades attached to the beam or frame, used for shallow working of the soil with minimum soil inversion (Fig.10). It works like a sweep which moves into top surface of the soil without inverting it.

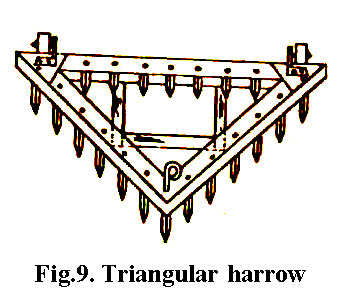

Reciprocating power harrow It is a harrow fitted with rigid tynes driven by the power take off in a reciprocating, transverse or rotary motion as the machine moves forward. The power harrow is rear mounted reciprocatory comb type. It has two horizontal oscillating arms having staggered pegs in two rows at 200 mm spacing (Fig.11). The two arms move in opposite directions and hence the implement is dynamically balanced. The amplitude of vibration is 200 mm and the frequency of operation is 400 cycles per minute. A transport wheel provided in the rear of the unit ensures depth control. The oscillating pegs break the clods and pulverize the soil to a fine tilth. The width of the harrow is 1500 mm. The field capacity of the unit is 0.5 ha/day.

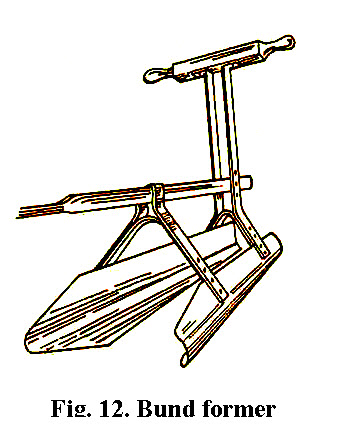

Bund former: It is used for making bunds or ridges by collecting the soil. Bunds are required to hold water in the soil, thereby one can conserve moisture and prevent run-off. The size of the bund former is determined by measuring the maximum horizontal distance between the two rear ends of the forming boards. Bund former consists of forming board, beam and handle (Fig.12).

Forming board: It is that part which gathers the soil to form the bund. It is made of mild steel. The thickness of the material is about 1.6 mm for light; 2.0 mm for medium and heavy soil. The forming boards are bolted to the form board supports.

Beam: Beam transmits the pull of the animals to the forming board and form board supports. It is made of hard wood.

Handle: Wooden handle is usually used for controlling the movement of the bund former.

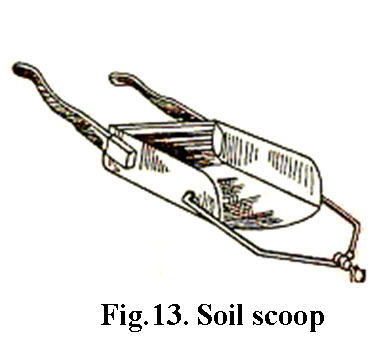

Soil scoop: Soil scoop is used in excavating ditches, clearing drain and moving soil over short distances. It consists of a blade, soil trough, hitching loop and handle (Fig.13).

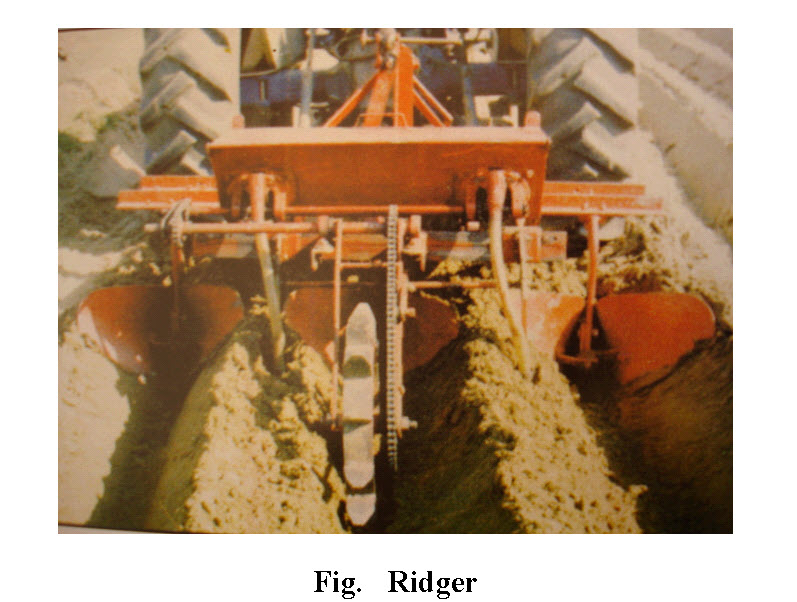

Ridger: It is an implement importantly used to form ridges required for sowing row crop seeds and plants in well-tilled soil. The ridger is also used for forming field or channels, earthing up and similar other operations. Ridger is also known as ridging plough and double mould board plough. The ridger generally has ’V’ shaped or wedge shaped share fitted to the frog. The nose or tip of share penetrates into the soil and breaks the earth. The mould boards lift, invert and also cast aside the soil, forming deep channels and ridges of the required size.

Leveler: Land leveling is expected to bring permanent improvement in the value of land. Leveling work is carried out to modify the existing contours of land so as to achieve certain objectives desired for efficient agricultural production system. These objectives include

(i) Efficient application of irrigation water,

(ii) Improved surface drainage,

(iii) Minimum soil erosion,

(iv) Increased conservation of rain water specially on dry lands and

(v) Provision of an adequate field size and even topography for efficient mechanization.

The animal drawn leveler consists of a wooden leveling board with a handle. Depending upon the soil condition, the shape of the board varies. In the front portion of the board two hooks are provided for connecting it to the yoke. If it happens to be tractor drawn then board hooks are connected to the back of the tractor with suitable link. If the weight requirement is more then either the extra bags of soil or sand or one or two persons can stand over the leveler while in operation.

Factors affecting penetration of disc harrow:

1) If weight of harrow is more penetration will be better

2) By increasing disc angle

3) By making discs sharper

4) Size of discs smaller and lesser concavity

5) By lowering hitch point

6) By regulating optimum speed (low speed).

What HP is necessary for pulling a harrow with 50 tynes each giving a resistance of 1 Kg. when speed of harrow is 5 km/hr.

Soil resistance = 50 X1 = 50 Kg.

HP required = (Kg) Resistance X Speed (m/min)

4500

= 50 X 5 X 1000 = 0.926 HP

4500 X 60