Site pages

Current course

Participants

General

MODULE 1. PRINCIPLES AND TYPES OF CUTTING MECHANISM

MODULE 2. CONSTRUCTION AND ADJUSTMENT OF SHEAR AND...

MODULE 3. CROP HARVESTING MACHINERY

MODULE 4. FORAGE HARVESTING, CHOPPING AND HANLING ...

MODULE 5. THRESHING MECHANICS, TYPES OF THRESHES, ...

MODULE 6. MAIZE HARVESTING AND SHELLING EQUIPMENT

MODULE 7. ROOT CROP HARVESTING EQUIPMENT

MODULE 8. COTTON PICKING AND SUGARCANE HARVESTING ...

MODULE 9. PRINCIPLES OF FRUIT HARVESTING TOOLS AND...

MODULE 10. HORTICULTURAL TOOLS AND GADGETS

LESSON 19. COTTON STRIPPERS, CONSTRUCTION AND WORKING PRINCIPLES

Cotton stripping machines are “once over” machines. In the stripper, all bolls whether opened or closed are removed from the plant in a single pass. Harvesting with a stripper is, therefore, usually delayed until the plants shed their leaves. Chemical defoliants are also some times applied to permit earlier stripping. An ideal variety for this type of machine is one with semi-dwarf plants with relatively short fruiting, short-nodded branches, storm-resistant bolls borne singly but having fairly fluffy locks for good extraction (stripping) and medium sized boll-stem. Stripping a variety that produces a widespread plant with numerous vegetative and fruiting branch results in low recovery of cotton and excessive field losses.

Cotton stripping machines are of single steel roller, double-steel roller or finger type. Double-brush nylon rollers used in place of steel rollers gives better performance. A plant population of 75-125 thousands per hectare in 1.2 m rows is commonly recommended for stripping harvesting. The double-roll cotton stripper may be centrally mounted on the tractor or it may be self-propelled. There are three different methods of conveying cotton from stripping unit viz. finger-beater rolls, augers and air. The finger-beater rolls are used with finger-type strippers. Auger-type of conveyer is suitable for roller-type strippers. Much dirt and trash can be screened out of the cotton through openings in the housing under the conveyers particularly where revolving beater conveyers are used.

Mechanical strippers

There are several factors that have contributed to popularity of strippers in preference to pickers. These are:

i) Lower initial investment & maintenance cost

ii) Better adapted to improved cotton varieties

iii) Improved ginning equipment for separating trash

iv) Trend toward closer row spacing

v) Good recovery of cotton in the field

vi) Higher harvesting speeds

vii) Suitable for picking and cotton suitable for stripping. Stripping a variety that produces a wide, spreading plant with numerous vegetative and fruiting branches results in low recovery of cotton and excessive field losses.

Varieties for narrow row planting should have the general characteristics indicated above for conventional row strippers varieties. However because of higher plant population fewer bolls per plant are needed to produce a given yield. Cotton bolls exhibiting too much of storm resistant characteristic although well adapted to striping are difficult to pick mechanically. The size of plant, the type of growth and the nature of the boll all have more influence on the efficiency of the mechanical picker than does yield. Where the plant characteristic are suitable, a machine will pick up high yielding cotton just as efficiently as it will low yield cotton.

Performance of mechanical cotton strippers: There are many factors such as plant characteristics, cultural practices etc affects the performance of all types of mechanical cotton strippers. The desirable plant type for cotton stripper is one which has relatively short-node fruiting branches 20-25 cm in length, less in height and has a stormy-resistant boll. The locks of story-resistant-type cotton are usually not very fluffy and are held tightly in the soil. Fluffy and loosely attached locks are easily caught and held between limbs and thus are pulled through the stripping space and lost. Every effort should be made to keep the field free of weeds, grass and vines. Pieces of grass collected with cotton are difficult to remove and if present in excess reduce the quality of cotton lint. The design and type of stripping unit also affects the performance of strippers.

Problem 1: A cotton picker is used for picking cotton bolls. The rotational speed of spindle is 1200 rpm at 2.5 km/h forward speed. Determine the revolution made by spindle of cotton picker in 500 m picking zone for chain belt arrangement.

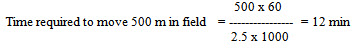

Solution:

In one minute spindle makes 1200 revolutions.

Number of revolutions made by spindle in 12 minutes = 12 x 1200 = 14400

Problem 2: How many revolutions will each spindle of cotton picker make in the picking zone for a chain-belt arrangement in which spindle has a rotational speed of 1200 rpm and remains in the picking zone during 100 cm of forward travel. Take the speed of cotton picker as 4.6 km/h.

Solution:

The time required to move 100 cm = (100 x 60)/ (4.6 x 105) minute = 0.01305 minute

In one minute the total number of revolutions made by spindle = 1200.

So, in 0.01305 minutes the number of revolutions made by spindle is:

= 0.01305 x 1200 = 15.65

Answer: Number of revolutions made by spindle = 15.65.