Site pages

Current course

Participants

General

MODULE 1. PRINCIPLES AND TYPES OF CUTTING MECHANISM

MODULE 2. CONSTRUCTION AND ADJUSTMENT OF SHEAR AND...

MODULE 3. CROP HARVESTING MACHINERY

MODULE 4. FORAGE HARVESTING, CHOPPING AND HANLING ...

MODULE 5. THRESHING MECHANICS, TYPES OF THRESHES, ...

MODULE 6. MAIZE HARVESTING AND SHELLING EQUIPMENT

MODULE 7. ROOT CROP HARVESTING EQUIPMENT

MODULE 8. COTTON PICKING AND SUGARCANE HARVESTING ...

MODULE 9. PRINCIPLES OF FRUIT HARVESTING TOOLS AND...

MODULE 10. HORTICULTURAL TOOLS AND GADGETS

LESSON 25. HORTICULTURAL TOOLS AND GADGETS AND GARDEN TOOLS

The need for special types of power units and/or cultivating implements arises when it is necessary to work between fruit trees, where planting distance has already been decided and equipment has to confirm it. Narrow rows of fruits sometimes necessitate the use of small tractors with matching equipment. There are special ploughs called hop ploughs suitable for very narrow work and turns two furrows to right and two to left simultaneously. Another type of implement desired is which can work as close to trees/plants on one side as possible without destroying the roots. Some of these implements are discussed here.

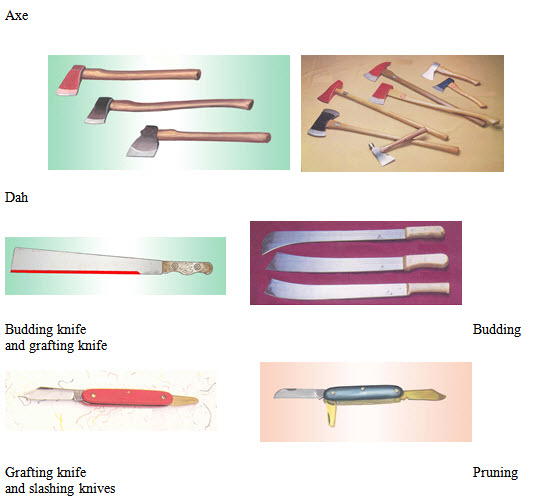

Horticultural hand tools (Fig. 1)

Hand tools are widely used in horticulture because many of the areas cultivated are too small or it is almost impossible for other machines to do the job near plants/trees efficiently. One such hand tool is spade, which can be used for digging, trenching and removing soil. Spades are available in normally two different sizes viz. one has blade 280 mm long and 190 mm wide and weighs 2.0-2.5 kg and another has blade 220 mm long and 140 mm wide and weighs 1.5-2.0 kg. The selection of spade depends on the type of soil and work to be done. The blade is made from tempered steel; however, some spades are also made of stainless steel. The blade should be kept vertical during digging, as it requires minimum efforts.

The forks are also commonly used as horticultural tools. They are available in different types depending upon the type of job to be done. Digging forks are used for digging in the soil already turned by spade. They normally have four prongs, which can be either round or square in section. Border forks are used as weeders in the border area of field. They are narrower and lighter than digging forks and normally have 3 or 4 prongs. Potato forks are specially made for lifting the potatoes in the field. While lifting the potatoes in the field soil automatically drops through and not much damage is made to tubers. In this tool, the prongs are much broader than digging fork and usually have 4 or 5 in numbers.

Garden rakes are commonly used as a horticultural tool to break the soil to fine tilth, and to gather the grass, stone and hedge clippings in the field. It has about 10 rigid teeth. Lawn rakes and hay rakes are also used for collecting grasses and tree leaves in the orchard, which are necessary to keep the area clean. They have normally 12-20 teeth depending upon the size.

Hoes are used to destroy the weeds and loosen the soil around the trees. There are two types of hoes; draw-hoe being pulled by the worker and push-hoe. Triangular headed hoes are also used as horticultural tool for making shallow drill usually in conjunction with a garden line. Garden line is generally used when seed sowing, trenching, lawn edging and transplanting operations is performed in the garden. It has 6-20 m nylon twine with a pin at one end and reel at other end where it can be wound for storage.

Shears are used for cutting grasses and hedges. They are of two types viz. hand shears and edging shears. Hand shears have blade 200-300 mm long with wooden or plastic handles. The cutting action takes place between the two blades, which are pivoted and material to be cut is sheared between them. Some shears have a pruning notch near the pivot of the blades so that thick twig can easily be cut. Edging shears are used for cutting lawn edges because they have handles about 1 m in length and attached at an angle to the blades. Secateurs are also small hand tools used for pruning bushes and shrubs. Turfing iron and turf lifters are used for edging lawns.

Pruning secateurs also known as pruning shears resembles a multipurpose combination pliers used in a workshop. The need of secateurs arose to cut the branches or twigs, which are difficult to cut by pruning knives. Being handy and easy to operate, it is considered to be an essential tool of the gardener in plant propagation. Various types of pruning secateurs are fabricated for removing or cutting of unwanted branches or twigs, cutting of scion sticks, defoliation of leaves from the sticks and topping of small trees. These are single cut, double cut, parrot nose cut, roll cut, bes cut, supa cut, replaceable blade type, easy cut, kiln cut etc. The pruning secateurs consist of two cutting blades or one cutting blade and an anvil, handle, volute spring to keep the blade and handle in open position and a locking device for keeping the secateurs in closed position. The blade is important part of the tool and is made from high carbon steel, tool steel or alloy steel. The blades are forged to shape, ground sharp at the cutting edge and hardened to 460-510 HB. Handles are made from aluminium or mild steel and in some cases a cover of plastic is provided on the arms of the handle. Usually the arms of the handle follow a fixed path during cutting operation but in some secateurs one of the arms of the handle is made rotating type for easy operation. For operation the branch or the twig is held in between the blades and handles pressed together which produces shearing action and cutting of the material. The secateurs are selected according to the operation and size of the twig or branch. The pruning secateurs are known by various names depending upon the shape of blades and are available in various sizes (150, 175, 200, 225, and 250 mm). The size refers to overall length of the secateurs. Cutting capacity is up to 20 mm diameter. Used for cutting of the unwanted branches or twigs of the orchard tree, vines, scion sticks, defoliation etc.

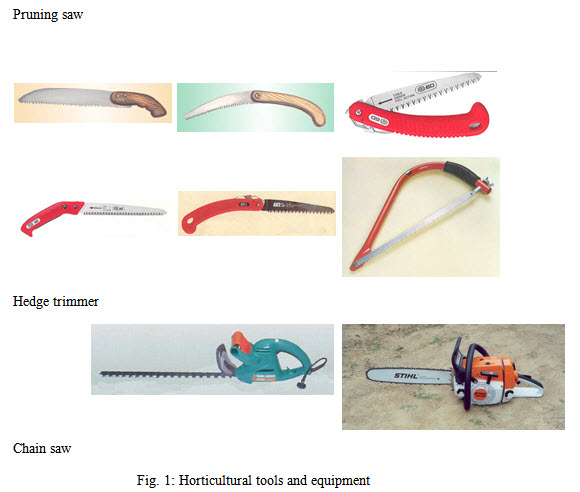

Chain saw: Chain saws are used in horticulture to trim dead or diseased wood from the field, to remove inconveniently placed branches and to fell undesired trees. They are also called power saws. It has an endless chain fitted with cutters, which run around a flat plate called the guide bar and does the cutting job. Chain saw is either manually operated or operated by a small two-stroke petrol engine. A sprocket fixed on engine shaft drives the chain, to which the guide bar is rigidly bolted. An electric motor or hydraulic power unit can also operate it.

Hedge cutters: It is also called hedge trimmer. A small petrol engine, compressed air, electric motor or 12 V batteries can operate portable hedge cutters. Cutting takes place between two blades, one of which reciprocates in close contact with a stationary one at a rate 33-66 strokes per minute. Some hedge cutters have an extension like a small saw on the end of moving blade, which can be used to cut branches that are too thick to be cut by blades. One type of hedge trimmer can be mechanically driven through a flexible drive. Some hedge trimmers have circular cutting head.

Pneumatic secateurs: The pneumatic secateurs, also known as pneumatic pruning shears, are used for pruning vines using pneumatic power. Gripping blade of the shear is stationary and shearing action is imparted by the other blade through the movement of piston, at the end of which it is fixed, with high-pressure air carried in a portable cylinder. The device offers effortless, accurate and swift cutting, at the same time ensuring the quality of vines. The double acting piston facilitates easy pruning of even large branches. The extension member helps access to branches inside canopy. The cutting head of the shear can be adjusted as needed across 360°.

Tree pruner: The tree pruner is a manually operated pruning tool for cutting of the branches or twigs of the orchard trees or plants in standing positions, which are beyond the reach of human hands for aeration and giving a shape for facilitating harvesting and adequate lighting. It essentially consists of a hooked anvil, spring actuated cutting blade, links for actuating the blades and a socket. A long wooden handle is inserted in the socket in order to access the high branches or twigs for cutting. A rope is attached to the link for actuating the cutting blade. The blade is important part of the tree pruner and is made from high carbon steel, tool steel or alloy steel. The blade is forged to shape and the cutting edge grounded sharp. The blade is hardened to 425-450 HB. For cutting operation the branch or twig is brought under the hook. The blade is actuated by pulling the rope, which cuts the twig due to shearing action. When the rope is held loose the blade returns to its original position due to spring action. The tree pruners are available in various sizes. The size of the tree pruner is known by its overall length. One of the typical sizes is 360 mm including the length of the socket. The cutting capacity of the tree pruner is about 20 mm diameter branch or twig.

Pruning saw: The pruning saw is manually operated hand tool for cutting or trimming of the branches, which are beyond the capacity of the secateur or tree pruner. Like carpenter saw it essentially consists of a serrated blade and a handle. The blade has a longer pitch to avoid clogging during operation in cutting of green branches. The blade comes in straight and curved design and is made from tool steel having a carbon content of more than 0.7 %. The cutting teeth are made sharp and hardened to 45-48 HRC. For efficient cutting the blade is provided with adequate rake and gullet angles. The handle is made from good quality wood and riveting joins the blade. For cutting the blade is repeatedly moved over the branch and cutting is done in forward stroke.

Chain saw: The chain saw is used to trim dead or diseased wood from trees, to remove inconveniently placed branches or fell trees. It is also called power saw and is a light and portable machine normally and operated by one person. Cutting is done by an endless chain fitted with cutters, which runs around a flat piece called the bar. The drive link of the chain runs in a groove, machined in the edge of the bar and is pulled along by the teeth of a sprocket, which engage them. The sprocket in turn is driven at full speed either by small two- stroke petrol engine or electric motor. The power to the chain is transmitted through a centrifugal clutch mounted on crankshaft of the engine. The chain is of roller type and has left and right hand cutters spaced alternately along its length. In front of each of the cutters is a small projection called a depth gauge whose purpose is to control the depth of cut made by the cutter.

Hedge shear: The hedge shear is used for pruning and trimming of hedge and giving it desired shape. It is also used for cutting of shrubs and removing of haphazard growth in gardens and lawns. The tool essentially consists of two blades with tangs. The tangs are inserted in the wooden handle and secured by ferrule. The cutting action takes place between two blades, which are pivoted, and the material to be cut is sheared between these blades. The blades are forged to shape and edges are ground to obtain a bevel angle just less than 90 degrees. It is important to maintain the desired cutting while sharpening these blades to obtain clean cut. The blade and tang are made in single piece from high carbon steel, tool steel or alloy steel and hardened to 420-470 HB. The handles are made from high quality wood. For operation the handles are pulled apart to open the blades. The material or hedge twigs to be cut are brought in between these blades and moving the handles inward shears the twigs. This action is repeated fast for trimming of the hedges and shrubs. Some of the models are provided with pruning notch near the pivot of blades for cutting of thick twigs.

Hedge trimmer: Hedge trimmer is used for trimming hedges, shrubs and brambles. It is also used for contouring plants in desired shapes and sizes for enhancing the aesthetics of the garden. Hedge trimmer consists of a cutter bar having two sets of reciprocating blades. The teeth along the top blade are diamond round and double edged to stay sharp for long. It can cut even branches of up to 16 mm in diameter. The cutter bar is driven either by engine or motor. The unit can be moved in various directions- to the left, right, upwards or downwards. A baffle guard is provided to protect the user from flying leaves, stems or branches. The motor power unit is provided with flexible chord, which permits the movement of the trimmer to all places in the garden. An extra trigger switch is integrated in the handle for quick, error free operation.