Site pages

Current course

Participants

General

Module 1. Hydraulic Basics

Module 2. Hydraulic Systems

MODULE 3.

MODULE 4.

MODULE 5.

MODULE 6.

MODULE 7.

MODULE 8.

19 April - 25 April

26 April - 2 May

LESSON 24. Construction Application Maintenance of Linear Actuators

Introduction

Linear actuator are the devices which receives pressure energy and converts it to mechanical output in the form of force and motion. A linear actuator gives force and motion outputs in a straight line. It is commonly known as a cylinder but is also referred to as a ram or linear motor. In the hydraulic systems, pump is utilized to make the flow of the fluid and valves are utilized to the flow of fluid , pressure in the circuit or direction of flow. Whereas, the actual purpose is achieved with the help of actuators. The actuators are converting the hydraulic fluid energy into useful work or mechanical output. This may be single-acting cylinder or double-acting cylinder.

Construction

The cylinder are generally constructed of cold drawn steel barrel or tube. The piston and rod are chrome plated and polished. Two end caps, and suitable oil seals are used to prevent leakages. A barrel is usually seamless steel tubing,or cast, and the interior is kept highly finished and very smooth. A steel piston rod is highly polished and usually hard chrome-plated to resist scoring. .

The end caps are screwed on to the tube, welded, attached by tie bolts or bolted flanges. If the cylinder barrel is cast, the head-end cap may be integral with it. Seals are provided in the rod end cap to keep the rod clean and to prevent

Application

Hydraulic systems have many requirements and therefore actuating cylinders are available in different shapes and sizes. A cylinder type actuator is versatile and may be the most trouble-free component of a hydraulic systems. A cylinder and a mechanical member of a unit to be actuated is required to be aligned properly. Any misalignment will cause excessive wear of a piston, a piston rod, and the seals etc.

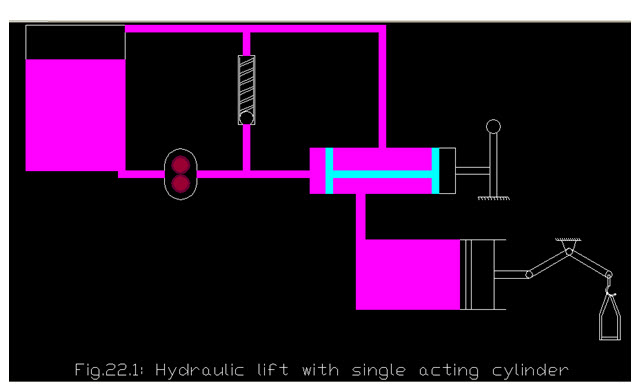

- Single-acting cylinders are used wherever hydraulic power is required for only one direction of motion. For example lifting, clamping and lowering work piece, in hydraulic lifts, lifting platforms and lowering and raising of implement in hydraulic lift of a tractor.

Mounting of cylinder

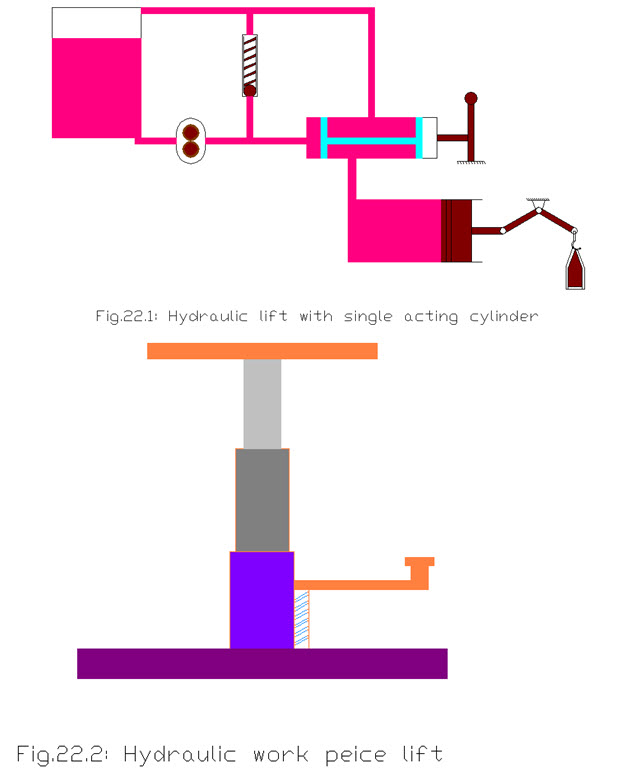

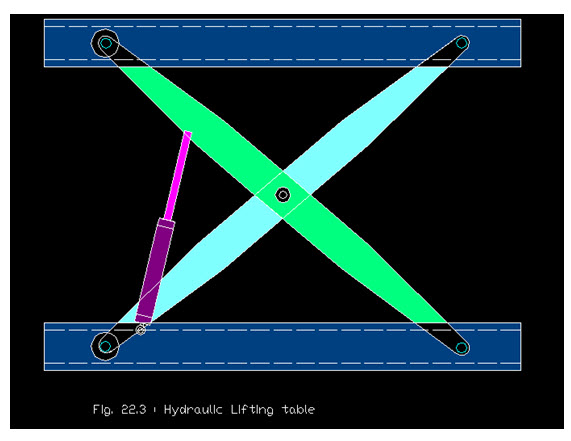

vertical mounting

when the return movement of the piston is brought with the help of external forces like lifting table

Lifting table

horizontal mounting

It is done in single-acting cylinders with spring-return. Like in hydraulic presses

Double Acting Cylinder

The movements generated by hydraulic cylinders are used for the followings-

Machine tools

Feed movements for tools or work piece

Clamping devices

Movements on presses

Movements on printing and injection moulding machines, etc.

Handling devices

- Lifting and lowering in fork-lift etc.

Moving equipment

Excavators

Loaders

Tractors

Tipper trucks

Maintenance of Linear Actuators

The linear actuators are the hydraulic cylinders, which are compact and simple in design. The seals and pivots are important to be considered. The following points are required to be viewed in maintaining cylinders-

External Leakage :

If a cylinder’s end caps are leaking, tighten them. If the leaks still do not stop, replace the gasket. If a cylinder leaks around a piston rod, replace the packing.

Internal Leakage :

If the leakage ocure after the piston seals inside a cylinder can cause sluggish movement . Piston leakage can be caused by worn piston seals or rings. Therefore replace all the seals and packings.

Creeping Cylinder :

If a cylinder creeps when stopped in midstroke, check for internal leakage

Sluggish Operation :

Some times air comes in a cylinder and cause the sluggish operation. Internal leakage in a cylinder is another cause. If sluggish operation there, check for oil of too high a viscosity or check for other, etc.

Loose Mounting :

If pivot points and mounts are loose, the bolts or pins are needed to be tightened.

Periodically check all the cylinders for loose mountings.

Misalignment :

Piston rods are required to work in line . If it is not so, the piston rods may be bent or get damaged. Hence go for proper alignment

Rotary actuators

Hydraulic actuators are the muscles of many machines. They are produced in varying sizes from miniature units to massive actuators. A rotary actuator is a device that produces a rotary motion or torque. The motion developed by an actuator may be either continuous rotation or an angular rotation..It basically transforms the hydraulic energy into rotary energy in the form of mechanical rotations which can be applied to the an object with the help of a shaft. These are also called hydraulic motors.