Site pages

Current course

Participants

General

Module 1. Introduction to by-products and waste ge...

Module 2. Waste management concepts

Module 3. Direct combustion of solid waste

Module 4. Thermo-chemical conversion of solid waste

Module 5. Bio-chemical conversion of solid waste

Module 6. Solid waste management

Module 7. Effluent treatment and disposal

Module 8. Presence of typical chemicals

19 April - 25 April

26 April - 2 May

Lesson 4.

India, one of the most populous countries of the world (17% of world population) is also counted among the largest growing economies. However the pace its development is hampered by the inadequate availability of energy vital for sustainable growth. While its population is increasing at a rate of 1.5 %, the energy consumption growth is rising at a rate of 9% per annum and this demand is expected to double by 2020. Country with the capacity to generate 1, 23,668 MW of power has a shortfall of 15, 000- 20,000 MW currently. In fact the country has only solid fuel like coal as the main natural occurring resource of significance. But the higher percentage of ash content associated with it make it fuel of inferior quality. Hence the country is always on lookout for alternate fuels that can fill up the gap and help to meet the ever increasing energy demand.

Country generates large volume of agricultural residue that has good potential to be processed into a regular source of agro based fuel. Currently after separating the valuable grains, the residual biomass (70% in case of rice straw and 30% in case of wheat straw) is considered waste that is used by rural poor to fire its hearth. However processing of such biomass by suitable densification technique can convert it into briquettes that can not only generate income for farmer but also provide energy for commercial and industrial applications. A study conducted by CII has pointed out that country has tremendous potential for energy generation through biomass and its residue (Table 4.1)

Table 4.1: Potential of energy production from biomass in India

|

Potential in India 16 000 MW (Excluding Co –generation) |

|

Installed capacity 630 MW |

|

Project under consideration 630 MW |

Source: CII- Godrej GBC publication RES-fact sheet- No 1 June 2004

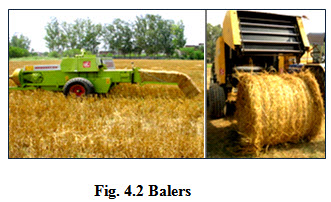

Bale

A bale is unit of compressed biomass like straw, pine needles, cotton or any other bio- material that is pressed into a specific size and shape (e.g. Round, rectangular or square) so that its density is increase which is so vital for handling, transportation, storage and even usage. A baler is used to compress a cut and raked crop (such as, straw from different crops, cotton etc.,) into compact bale that are easy to handle, transport, and store. Several different types of balers are commonly used, each producing a different type of bales – rectangular or cylindrical, of various sizes, bound with twine, strapping or wire. Rectangular bales are easier to transport than round bales, since there is little risk of the bale rolling off the back of a flatbed trailer. The rectangular shape also saves space and allows a complete solid slab of hay to be stacked for transport and storage.

Fig.4.1 Rectangular bales

Operation of Baler

To form the bale, the material to be baled, (which is often hay or straw) in the windrow is lifted by tines in the baler's pickup. This material is then dragged into a chamber that runs the length of one side of the baler. A combination plunger and knife moves back and forth in the front end of this chamber. The knife, positioned just ahead of the plunger, cuts off the material at the spot where it enters the chamber from the pickup. The plunger rams the material rearwards, compressing it into the bales. A measuring device measures the amount of material that is being compressed and, at the appropriate length it triggers the mechanism (the knotter) that wraps the twine around the bale and ties it off. As the next bale is formed the tied one is driven out of the rear of the baling chamber onto the ground or onto a special wagon hooked to the rear of the baler. This process continues as long as there is material to be baled, and twine to tie with it.

Bales of 30 x 30 x 60 cm ( 12 x 12 x 24 in.) or 45 x 45 x 60 cm (18 x 18 x 24 in.) are formed, and are tied with two or three wires, to prevent them from re-expanding. A hydraulic press is employed for this purpose, similar to a press for hay. The bales of biomass (e.g. bagasse, a sugarcane fiber residue after extraction of juice) have a density of 400-600 kg/m3 (25-40 lb. /cu.ft.), according to the pressure employed. They are then stacked in “draught board” fashion so as to allow air to circulate between the bales. In this way then dry more rapidly. However, this practice is discouraged in certain countries, such as the Philippines, where it is considered that it allows fire to spread more rapidly. On the other hand, it decreases the risk of spontaneous combustion. In two or three months, the bagasse loses part of its moisture, which decreases from 45-50% to about 25%, a value at which it becomes stable. The baggage bales then weight only about 300-400 kg/m3)20-25 lb./cu.ft.). Bagasse is baled while moist, as it leaves the mills, can give rise to spontaneous combustion when stacked in a large pile. Bagasse baled and sticked in “draught board” fashion and sheltered from the weather may be stored for a long time. When a long period of storage is foreseen, it is advantageous to sprinkle powdered boric acid on the stack proportionately as the stack is built up.

Briquettes

Briquettes are the eco-friendly renewable source of energy that avoids adding fossil carbon to the atmosphere. Biomass briquette is one which takes waste products such as saw dust etc and compresses it and extrudes it to make a reconstituted log which can replace the firewood. The natural lignin in the biomass binds the particles of wood/ agricultural residue together to form a solid. The burning of briquette is far more efficient than burning firewood as the moisture content briquette can be as low as 5% where as green firewood may contain as high as 65% moisture.

Biomass Briquettes are made from the agricultural waste, forest waste and industrial waste. The major residues are rice husk, coir pitch, jute sticks, sugarcane bagasse, groundnut shell, mustard stalks, cotton sticks, sawdust, caster shells/stalks, wood chips, bamboo dust, tobacco waste, tea waste, paddy straw, wheat straw, sunflower stalks, palm husk, soyabean husk, veneer residues, barks and straws, forestry waste etc.

Advantages of Briquettes

-

Eco- friendly and renewable energy fuel

-

Economical and cheaper than other solid fuels like wood and coal

-

Higher thermal calorific value (around 4000 Kcal/Kg)

-

Pollution free because there is no sulphur or any other hazardous materials.

-

Lower ash content (2 – 5) % and there is no fly ash when burnt.

-

They are of consistent quality, high burning efficiency due to low moisture content and uniform size.

-

Easy for transportation, feeding and combustion due to unique cylindrical shape

-

Low ash content (10%) in comparison to coal (25 – 40 %) resulting in less boiler ash disposal problems.

-

Briquettes are usually produced near the biomass production and consumption centre thus supplies don’t depend on erratic transport from long distances.

-

Easy handling compared to loose agro waste having low bulk density.

Uses of briquettes in various industries

Gasifier system applications Chemical industry

Leather industry Rubber industry

Textile industry Refractory industry

Dyeing units Brick making units

Ceramic industry Food processing industry

Any industrial thermal applications

A major disadvantage of agricultural residues as a fuel is their low bulk density, which makes handling difficult, transport and storage expensive, and gives rise to poor combustion properties. However, these problems can be overcome by compacting, with a compression ratio of approximately 7:1, the loose biomass to form briquettes.

Following are the few different densification techniques available:

- Piston press

This press was developed in the Switzerland by Fred Hausmann. It consists of three main parts i.e. a die, a cylinder and piston and a driving unit consisting of a massive flywheel. The material is fed into the cylinder which is then compressed by piston into slightly tapering die. The legnins contained in the biomass begin to flow and act as a natural glue to bind the compressed material. When cylindrical material exit the die, legnins solidify and hold it together to form briquette which breaks into pieces 10-30 centimetres long. The diameter of the briquette is related to the capacity of the press. The pressure in the compression zone is in the range of 110 -140 MPa.

Capacity = Volume of material that can be fed in front of piston in each stroke X Number of stokes / time .Capacity by weight depends upon the density of material before compression.

Most of the units presently installed in India are of the reciprocating piston type, where the biomass is extruded through a die by a reciprocating ram at a very high pressure.

- Screw press

This press was developed in USA in 1930. In this press biomass is fed continuously into a cylindrical die. The die is often heated to raise the temperature to the point where legnin flow occurred. Pressure builds up smoothly along the screw rather than discontinuously under impact of a piston. If die is not heated then temperature may not rise sufficiently to cause legnin flow and a binding material may have to be added. This can be molasses, starch or some other cheap organic material. If die is heated, then temperature is normally raised to 250 – 300 °C, which produces a good quality briquette from virtually all organic foods, provided the initial moisture is below 15%. The briquettes from screw press are often of higher quality than from piston press unit being harder and less likely to break along natural fracture lines.

Screw presses are usually sized in the range 75-250 kg/in though larger machines are available. The maintenance costs of screw presses are usually much higher because of the considerable wear on the screws which have to be re-built rather frequently. In terms of briquette quality and production procedure the screw press is superior. The briquettes produced by a screw extruder helps in uniform and efficient combustion, with significant reductions in smoke. Also these briquettes can be carbonized which increases their energy density.

3. Pellet press

Such machines were originally developed for the production of animal feed stuffs. In these rollers run over a perforated surface and material is pushed into a hole each time a roller pass over. The diameter of the briquette is very small (10- 30 mm). They are expensive and have high throughputs of 5-20 t/hr. for a single unit.

Facilities needed for value addition to biomass

1. Storage

Storage of raw material (agricultural residue) is likely to be in the form of open storage piles adjacent to the process plant. Normally there is no need to cover the pile. When processing dry matter, some kind of coverage is necessary in order to enable operation in the periods of rain. Generally tarpaulins and sheds will offer some storage. If a drier is included in the process, a storage bin must be installed for intermediate storage of dried material before Briquetting. The briquetted end product will always be stored under cover as briquettes will crumble and disintegrate if rained upon.

2. Handling

Handling normally makes up the largest group of equipment in large automated plants. However for a small mechanical piston press, the simple solution for handling briquettes is letting the machine push the material all the way to the product storage. Turns, even U-turns are possible since the material is still warm and rather soft.

3. Comminution

The need for size reduction depends upon the material. The density of briquette should be more than 1000 kg/m3 (i.e. individual briquette should sink in water). This density is set by the density of raw material. Density is also affected to a significant degree by the particle size of the raw material. Finely ground material will make dense briquette. Moisture content is another parameter which affects the density. All these factors are very important for briquetting paddy straw. So comminution is must in this case. This size reduction is carried out by hammer mill as it can crush the paddy straw into coarse fine fraction.

4. Classification

To insure that paddy straw after crushing is clean and contains no oversize particles, there must be screening operation. Normally over sized material is removed and sent back into the hammer mill. Mechanical piston press (commonly used in India) is especially sensitive to large particle entering the press.

5. Drying

The moisture content of the crushed paddy straw feed should not be more than 15%. So in case of higher moisture, thermal drying is commonly used. For this some of the briquettes are burnt to produce hot air to be used for drying raw material

6. Densification

This is the last stop for producing briquettes. Among the various methods ,mechanical piston press is preferred in the country.