Site pages

Current course

Participants

General

MODULE 1.

MODULE 2.

MODULE 3.

MODULE 4.

MODULE 5.

MODULE 6.

MODULE 7.

MODULE 8.

MODULE 9.

MODULE 10.

LESSON 2. Rolled Structural Steel Sections

2.1 INTRODUCTION

The steel sections manufactured in rolling mills and used as structural members are known as rolled structural steel sections. The steel sections are named according to their cross sectional shapes. The shapes of sections selected depend on the types of members which are fabricated and to some extent on the process of erection. Many steel sections are readily available in the market and have frequent demand. Such steel sections are known as regular steel sections. Some steel sections are rarely used. Such sections are produced on special requisition and are known as special sections. ‘ISI Handbook for Structural Engineers’ gives nominal dimensions, weight and geometrical properties of various rolled structural steel sections.

2.2 TYPES OF ROLLED STRUCTURAL STEEL SECTIONS

The various types of rolled structural steel sections manufactured and used as structural members are as follows:

-

Rolled Steel I-sections (Beam sections).

-

Rolled Steel Channel Sections.

-

Rolled Steel Tee Sections.

-

Rolled Steel Angles Sections.

-

Rolled Steel Bars.

-

Rolled Steel Tubes.

-

Rolled Steel Flats.

-

Rolled Steel Sheets and Strips.

-

Rolled Steel Plates.

2.3 ROLLED STEEL BEAM SECTIONS

The rolled steel beams are classified into following four series as per BIS : (IS : 808-1989)

-

Indian Standard Joist/junior Beams ISJB

-

Indian Standard Light Beams ISLB

-

Indian Standard Medium Weight Beams ISMB

-

Indian Standard Wide Flange Beams ISWB

The rolled steel columns/heavy weight beams are classified into the following two series as per BIS (IS : 808-1989)

-

Indian Standard Column Sections ISSC

-

Indian Standard Heavy Weight Beams ISHB

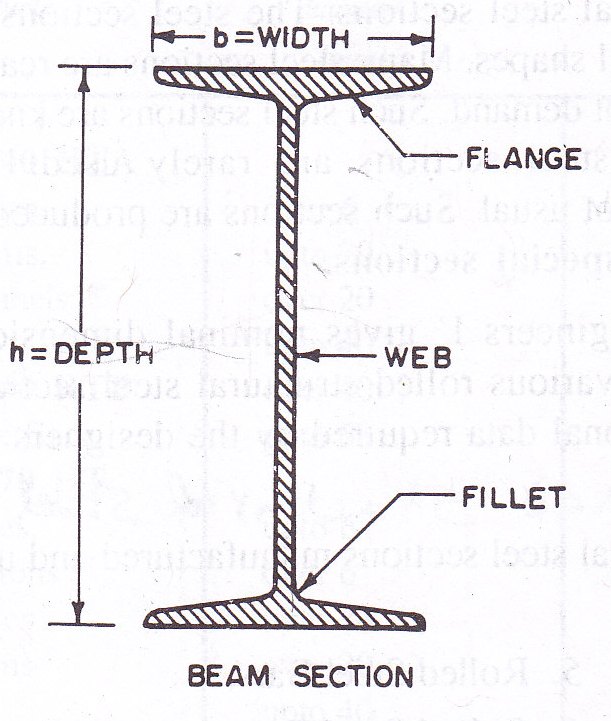

The cross section of a rolled steel beam is shown in Fig. 2.1. The beam section consists of web and two flanges. The junction between the flange and the web is known as fillet. These hot rolled steel beam sections have sloping flanges. The outer and inner faces are inclined to each other and they intersect at an angle varying from 1½ to 8˚ depending on the section and rolling mill practice. The angle of intersection of ISMB section is 8˚. Abbreviated reference symbols (JB, LB, MB, WB, SC and HB) have been used in designating the Indian Standard Sections as per BIS (IS 808-1989)

The rolled steel beams are designated by the series to which beam sections belong (abbreviated reference symbols), followed by depth in mm of the section and weight in kN per metre length of the beam, e.g., MB 225 @ 0.312 kN/m. H beam sections of equal depths have different weights per metre length and also different properties e.g., WB 600 @ 1.340 kN/m, WB 600 @ 1.450 kN/m, HB 350 @0.674 kN/m, HB 350 @0.724 kN/m.

I-sections are used as beams and columns. It is best suited to resist bending moment and shearing force. In an I-section about 80 % of the bending moment is resisted by the flanges and the rest of the bending moment is resisted by the web. Similarly about 95% of the shear force is resisted by the web and the rest of the shear force is resisted by the flanges. Sometimes I-sections with cover plates are used to resist a large bending moment. Two I-sections in combination may be used as a column.

2.4 ROLLED STEEL CHANNEL SECTIONS

The rolled steel Channel sections are classified into four categories as per ISI, namely,

-

Indian Standard Joist/Junior Channels ISJC

-

Indian Standard Light Channels ISLC

-

Indian Standard Medium Weight Channels ISMC

-

Indian Standard Medium Weight Parallel Flange Channels ISMCP

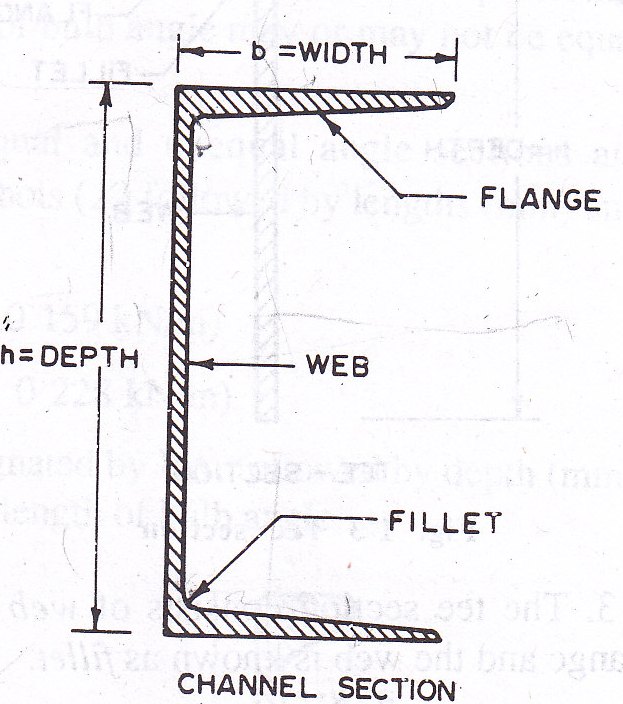

The cross section of rolled steel channel section is shown in Fig 2.2. The channel section consists of a web and two flanges. The junction between the flange and the web is known as fillet. The rolled steel channels are designated by the series to which channel section belong (abbreviated reference symbols), followed by depth in mm of the section and weight in kN per metre length of the channel, e.g., MC 225 @ 0.261 kN/m

Channels are used as beams and columns. Because of its shape a channel member affords connection of an angle to its web. Built up channels are very convenient for columns. Double channel members are often used in bridge truss. The channels are employed as elements to resist bending e.g., as purlins in industrial buildings. It is to note that they are subjected to twisting or torsion because of absence of symmetry of the section with regards to the axis parallel to the web, i.e., yy-axis. Therefore, it is subjected to additional stresses. The channel sections are commonly used as members subjected to axial compression in the shape of built-up sections of two channels connected by lattices or batten plates or perforated cover plates. The built-up channel sections are also used to resist axial tension in the form of chords of truss girders.

As per IS : 808-1989, following channel sections have also been additionally adopted as Indian Standard Channel Secions

-

Indian Standard Light Channels with parallel flanges ISLC(P)

-

Medium weight channels MC

-

Medium weight channels with parallel flanges MCP

-

Indian Standard Gate Channels ISPG

In MC and MCP channel sections, some heavier sections have been developed for their intended use in wagon building industry. The method of designating MC and MCP channels is also same as that for IS channels.

2.5 ROLLED STEEL TEE SECTIONS

The rolled steel tee sections are classified into the following five series as per ISI:

-

Indian Standard Normal Tee Bars ISNT

-

Indian Standard Wide flange Tee Bars ISHT

-

Indian Standard Long Legged Tee Bars ISST

-

Indian Standard Light Tee Bars ISLT

-

Indian Standard Junior Tee Bars ISJT

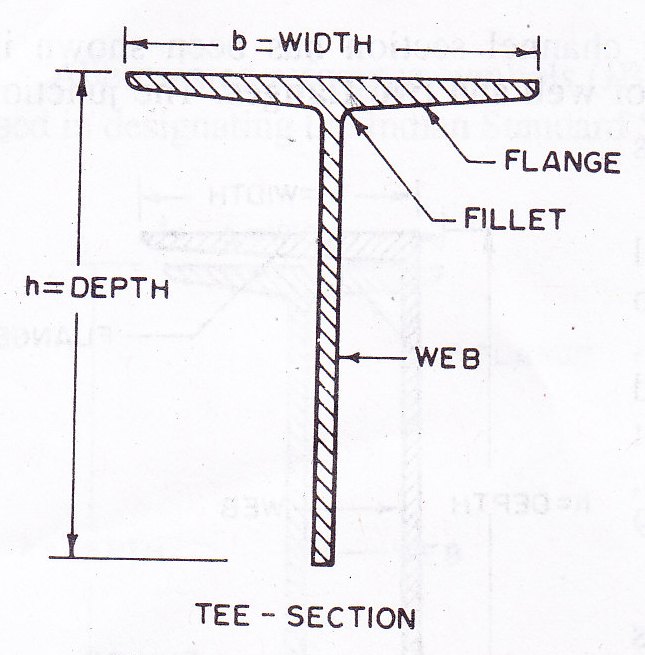

The cross section of a rolled steel tee section has been shown in Fig. 2.3. The tee section consists of a web and a flange. The junction between the flange and the web is known as fillet. The rolled steel tee sections are designated by the series to which the sections belong (abbreviated reference symbols) followed by depth in mm of the section and weight in kN per metre length of the Tee, e.g., HT 125 @ 0.274 kN/m. The tee sections are used to transmit bracket loads to the columns. These are also used with flat strips to connect plates in the steel rectangular tanks.

A per IS: 808-1984, following T-sections have also been additionally adopted as Indian Standard T-sections.

-

Indian Standard deep legged Tee bars ISDT

-

Indian Standard Slit medium weight Tee bars ISMT

-

Indian Standard Slit Tee bars from I-sections ISHT

It is to note that as per IS 808 (part II) 1978, H beam sections have been deleted.

2.6 ROLLED STEEL ANGLE SECTIONS

The rolled steel angle sections are classified in to the following three series.

-

Indian Standard Equal Angles ISA

-

Indian Standard Unequal Angles ISA

-

Indian Standard Bulb Angles ISBA

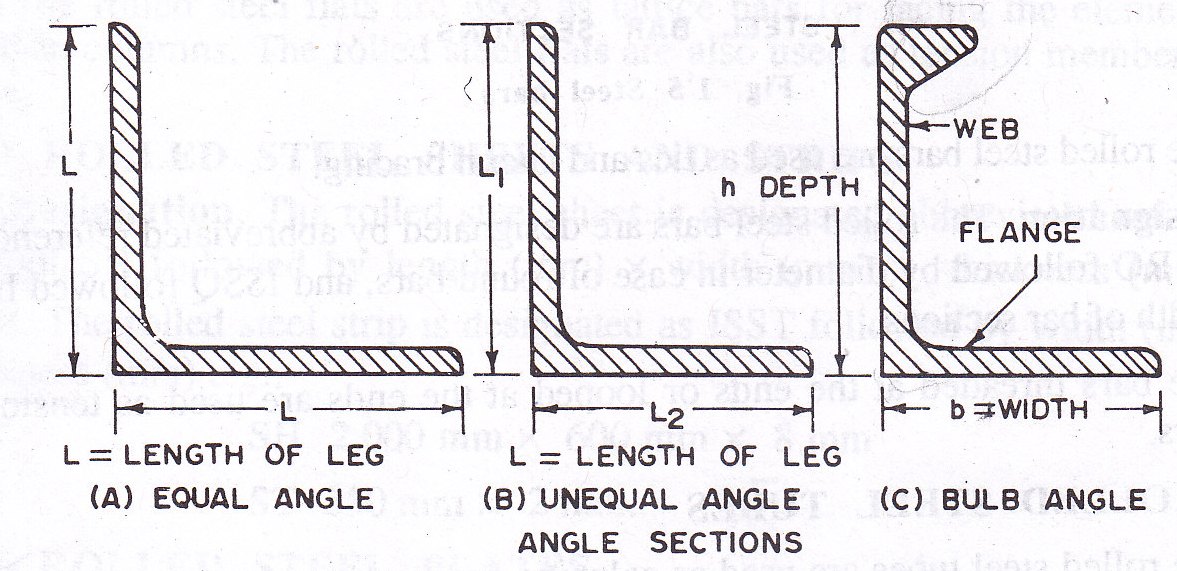

Angles are available as equal angles and unequal angles. The legs of equal angle sections are equal and in case of unequal angle section, length of one leg is longer than the other. Thickness of legs of equal and unequal angle sections are equal. The cross section of rolled equal angle section, unequal angle section and that of bulb angle section is shown in Fig. 2.4. The bulb angle consists of a web a flange and a bulb projecting from end of web.

The rolled steel equal and unequal angle sections are designated by abbreviated reference symbols ∟ followed by length of legs in mm and thickness of leg, e.g.,

∟130 x 130 x 8 mm (∟130 130 @ 0.159 kN/m)

∟200 x 100 x 10 mm (∟ 200 100 @ 0.228 kN/m)

The rolled steel bulb angles are designated by BA, followed by depth in mm of the section and weight in kN per metre length of bulb angle.

Angles have great applications in the fabrications. The angle sections are used as independent sections consisting of one or two or four angles designed for resisting axial forces (tension and compression) and transverse forces as purlins. Angles may be used as connecting elements to connect structural elements like sheets or plates or to form a built up section. The angle sections are also used as construction elements for connecting beams to the columns and purlins to the chords of trusses in the capacity of beam seats, stiffening ribs and cleat angles. The bulb angles are used in the ship buildings. The bulb helps to stiffen the outstanding leg when the angle is under compression.

As per IS : 808-1984, some supplementary angle sections have also additionally adopted as Indian Standard angle sections. However prefix ISA has been dropped. These sections are designated by the size of legs followed by thickness e.g., ∟200 150 x 15.

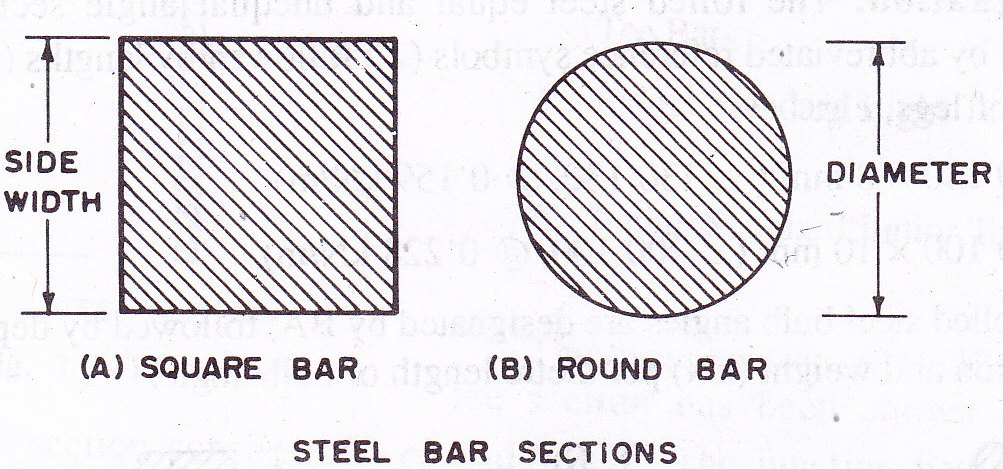

2.7 ROLLED STEEL BARS

The rolled steel bars are classified in to the following two series:

-

Indian Standard Round Bars ISRO

-

Indian Standard Square Bars ISSQ

The rolled steel bars are used as ties and lateral bracing. The cross sections of rolled steel bars are shown in Fig. 2.5. The rolled steel bars are designated by abbreviated reference symbol RO followed by diameter in case of round bars and ISSQ followed by side width of bar sections. The bars threaded at the ends or looped at the ends are used as tension members.

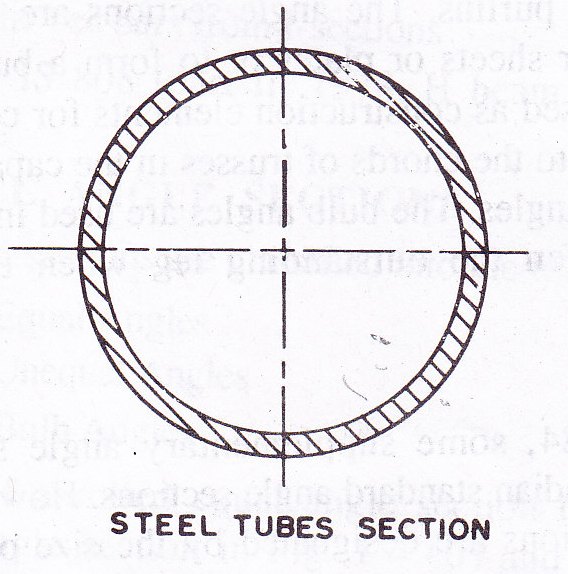

2.8 ROLLED STEEL TUBES

The rolled steel tubes are used as columns and compression members and tension members in tubular trusses. The rolled steel tubes are efficient structural sections to be used as compression members. The steel tube sections have equal radius of gyration in all directions. The cross section of rolled steel tube is shown in Fig. 2.6.

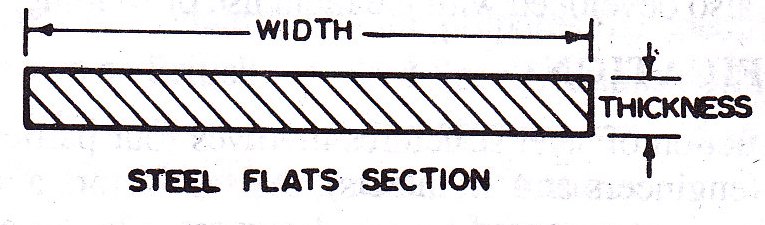

2.9 ROLLED STEEL FLATS

The rolled steel flats are used for lacing of elements in built up members, such as columns and are also used as ties. The cross section of rolled steel flat is shown in Fig. 2.7. the rolled steel flats are designated by width in mm of the section followed by letters (abbreviated reference symbol) F and thickness in mm, e.g., 50 F 8. This means a flat of width 50 mm and thickness 8 mm. The rolled steel flats are used as lattice bars for lacing the elements of built up columns. The rolled steel flats are also used as tension members and stays.

2.10 ROLLED STEEL SHEETS AND STRIPS

The rolled steel sheet is designated by abbreviated reference symbol SH followed by length in mm x width in mm x thickness in mm of the sheet. The rolled steel strip is designated as ISST followed by width in mm x thickness in mm, e.g., SH 2000 x 600 x 8 and ISST 250 x 2.

2.11 ROLLED STEEL PLATES

The rolled steel plates are designated by abbreviated reference symbol PL followed be length in mm x width in mm x thickness in mm of the plates, e.g., PL 2000 x 1000 x 6.

The rolled steel sheets and plates are widely used in construction. Any sections of the required dimensions, thickness and configuration may be produced by riveting or welding the separate plates. The rolled plates are used in the web and flanges of plate girders, plated beams and chord members and web members of the truss bridge girders. The rolled steel plates are used in special plate structures, e.g., shells, rectangular and circular steel tanks and steel chimneys.

2.12 RECENT DEVELOPMENTS IN SECTIONS

The rolled steel beam sections with parallel faces of flanges are recently developed. These beam sections are called as parallel flange sections. These sections have increased moment of inertia, section modulus and radius of gyration about the weak axis. Such sections used as beams and columns have more stability. Theses sections possess ease of connections to other sections as no packing is needed as in beams of slopping flanges. The parallel flange beam sections are not yet rolled in our country.

New welded sections using plates and other steel sections are developed because of welding. The development of beams with tapered flanges and tapered depths is also due to welding. The open web sections and the castellated beams were also developed with the rapid use of welding.

Fig. 2.1 Beam section Fig. 2.2 Channel section

Fig. 2.3 Tee section

Fig. 2.4 Angle section

Fig. 2.5 Bar section

Fig. 2.6 Tube section

Fig. 2.7 Flat section