Site pages

Current course

Participants

General

MODULE 1. Overview of renewable energy sources

MODULE 2. Characterization of Biomass

MODULE 3. Thermochemical conversion Technology (TCCT)

MODULE 4. Biochemical conversion Technology-Biogas...

MODULE 5. Bio-fuels (BCCT)

MODULE 6. Solar Energy Conversion System (SECS)

MODULE 7. Hydro-Energy Conversion System (HECS)

MODULE 8. Wind Energy Conversion System (WECS)

MODULE 9. Ocean Energy Conversion System (OECS)

MODULE 10. Energy conservation in agriculture

LESSON 31. Ocean Thermal Energy Conversion (OTEC) system

Coal, oil, gas and nuclear energy are the major sources of primary energy, (conventional sources of energy), which is followed by renewable energy sources, combustible wastes (biomass, animal products, municipal wastes, industrial wastes), hydro, and other sources. The world is unlikely to run out of energy in the near future. Also, the current patterns of energy production and use have destructive impacts on the environment and, in recent years, environmental issues such as possible climate change resulting from greenhouse gas emissions have thrown the spotlight onto the links between energy and the global environment. At the same time, there is a need, especially in developing countries, for higher levels of energy supply and use to fuel economic development. The energy shortfall hinders the economic and social development of most of the developing countries.

Hence, there is a need for search of suitable energy systems to meet out the energy demand in all layers of human civilization. Due to the known problems in conventional energy sources, the substitute renewable energy sources such as solar, wind, biomass gadgets are developed for energy generation. Still the energy gap is large and there is a stress to find out alternate energy systems available in the earth. As a result of this search it is found out that the sources such as tidal energy, ocean thermal energy, wave energy, mini and micro hydro systems and geothermal energy have exhaustive energy potential if properly utilized. The systems like fuel cell, thermoelectric convertors, thermionic converters, fluid dynamic convertor and magneto-hydro dynamic generators can also be used in the energy generation.

Ocean thermal energy

The oceans cover a little more than 70 percent of the Earth's surface. This makes them the world's largest solar energy collector and energy storage system. On an average day, 60 million square kilometers (23 million square miles) of tropical seas absorb an amount of solar radiation equal in heat content to about 250 billion barrels of oil. If less than one-tenth of one percent of this stored solar energy could be converted into electric power, it would supply more than 20 times the total amount of electricity consumed in the United States on any given day.

OTEC, or ocean thermal energy conversion, is an energy technology that converts solar radiation to electric power. OTEC systems use the ocean's natural thermal gradient—the fact that the ocean's layers of water have different temperatures—to drive a power-producing cycle. As long as the temperature between the warm surface water and the cold deep water differs by about 20°C (36°F), an OTEC system can produce a significant amount of power. The oceans are thus a vast renewable resource, with the potential to help us produce billions of watts of electric power. This potential is estimated to be about 1013 watts of baseload power generation, according to some experts. The cold, deep seawater used in the OTEC process is also rich in nutrients, and it can be used to culture both marine organisms and plant life near the shore or on land.

Applications

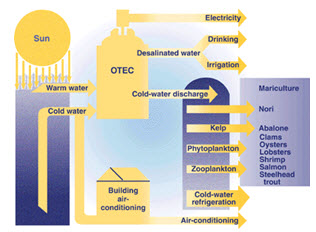

Ocean thermal energy conversion (OTEC) systems have many applications or uses. OTEC can be used to generate electricity, desalinate water, support deep-water mariculture, and provide refrigeration and air-conditioning as well as aid in crop growth and mineral extraction. These complementary products make OTEC systems attractive to industry and island communities even if the price of oil remains low.

OTEC can also be used to produce methanol, ammonia, hydrogen, aluminum, chlorine, and other chemicals. Floating OTEC processing plants that produce these products would not require a power cable, and station-keeping costs would be reduced.

Electricity Production

Three types of OTEC systems can be used to generate electricity:

Closed-cycle plants circulate a working fluid in a closed system, heating it with warm seawater, flashing it to vapor, routing the vapor through a turbine, and then condensing it with cold seawater. Open-cycle plants flash the warm seawater to steam and route the steam through a turbine. Hybrid plants flash the warm seawater to steam and use that steam to vaporize a working fluid in a closed system.

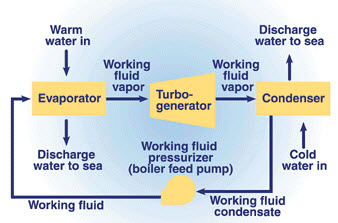

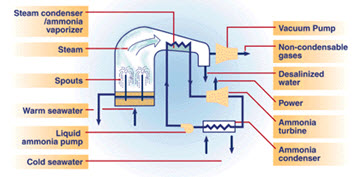

Closed-Cycle OTEC System

In the closed-cycle OTEC system, warm seawater vaporizes a working fluid, such as ammonia, flowing through a heat exchanger (evaporator). The vapor expands at moderate pressures and turns a turbine coupled to a generator that produces electricity. The vapor is then condensed in another heat exchanger (condenser) using cold seawater pumped from the ocean's depths through a cold-water pipe. The condensed working fluid is pumped back to the evaporator to repeat the cycle. The working fluid remains in a closed system and circulates continuously.

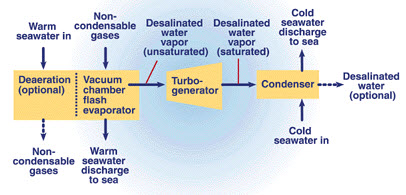

Open-Cycle OTEC System

In an open-cycle OTEC system, warm seawater is the working fluid. The warm seawater is "flash"-evaporated in a vacuum chamber to produce steam at an absolute pressure of about 2.4 kilopascals (kPa). The steam expands through a low-pressure turbine that is coupled to a generator to produce electricity. The steam exiting the turbine is condensed by cold seawater pumped from the ocean's depths through a cold-water pipe. If a surface condenser is used in the system, the condensed steam remains separated from the cold seawater and provides a supply of desalinated water.

Hybrid OTEC System

A hybrid cycle combines the features of both the closed-cycle and open-cycle systems. In a hybrid OTEC system, warm seawater enters a vacuum chamber where it is flash-evaporated into steam, which is similar to the open-cycle evaporation process. The steam vaporizes the working fluid of a closed-cycle loop on the other side of an ammonia vaporizer. The vaporized fluid then drives a turbine that produces electricity. The steam condenses within the heat exchanger and provides desalinated water.

The electricity produced by the system can be delivered to a utility grid or used to manufacture methanol, hydrogen, refined metals, ammonia, and similar products. Now let's take a closer look at some of the main components of an OTEC system—specifically, the heat exchangers, evaporators, turbines, and condensers.

Tidal energy

75% of the planet's surface consists of water. Water has easily fufilled our every need in many ways. The possibilities of utilizing the power of the oceans by pollution free Tidal Power generation is most attractive. Tidal Power has been used to limited extent over several centuries but only recently has any significant effort been put forth to realizing its vast potential

Introduction to tides

Tides are the alternating rise and fall of the surface of the seas and oceans. They are due mainly to the gravitational attraction (pull) of the moon and sun on the rotating earth. Two high and two low tides occur daily. Both the moon and sun affect the tides, but since the moon is much closer to the earth (384,400 km instead of 149,600,000 km), it has more than twice the effect of the sun, even though it is much smaller. So, to understand tides it's best to start with the moon and the lunar tide. The earth isn't fixed rigidly in space, and as the moon orbits, it attracts the earth round in a monthly orbit of its own. So the earth has a small orbit caused by the moon in addition to its annual one round the sun. It is the gravitational pull of the moon on the earth which keeps the earth in its monthly orbit.

The pull of the moon's gravity is just enough to keep the earth in its monthly orbit, but it is a bit stronger on the surface of the earth facing the moon (near side) and weaker on the far side. This means that on the near side, the moon tends to pull anything that's free to move towards it. In the same way, on the far side, there isn't quite enough gravitational pull, so that anything that's free to move tends to fly off, away from the moon. So on the near side they are pulled into a bulge towards the moon, and on the far side, they pile up into a bulge away from the moon.

As the earth spins, different parts of the world move under the two bulges of high water and experience high tides, giving the familiar two tides a day around Britain. In some parts of the world, local effects can mean only one tide a day, or even none.

Between the two bulges are two troughs of low water, producing two low tides a day. The sun also creates a very similar though smaller effect (the solar tide) and it is the interaction of the lunar and solar tides that causes spring and neap tides.

Springs and neaps

Tides change in height - low water level and high water level vary throughout the month. The tides build up to a maximum and fall to a minimum twice a month. The tides with the biggest difference between high and low water are called springs and those with the smallest are called neaps.

Spring tides happen just after every full and new moon, when the sun, moon and earth are in line. That's when lunar and solar tides line up and reinforce each other, making a bigger total tide. Neap tides occur when the moon is in the first or third quarter - when the sun, earth and moon form a right angle. The lunar high tide coincides with the solar low tide and they partly cancel out, giving a small total tide.

The regular motion of the sun, moon and earth cause spring tides to occur roughly 36 to 48 hours after the full or new moon, and for any given location, always at roughly the same time of day. For example at Liverpool, the spring tides are generally around midnight and midday.

Not all spring tides are the same size. Springs nearest the equinoxes (21 March and 21 September - when day and night are of equal length all over the world) are slightly bigger. The explanation for this is very complex and won't be given here. (http://www.pol.ac.uk/home/insight/tideinfo.html)

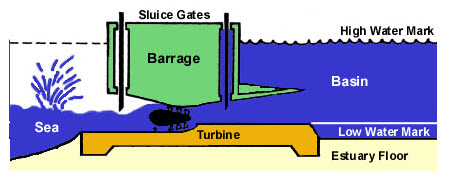

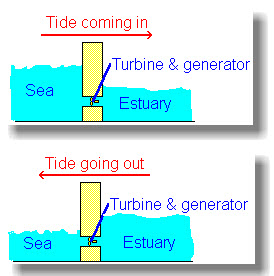

In order to create enough electricity to be economically feasible, the size and configuration of the structure has to be increased tremendously. Tidal Energy consists of generating kinetic energy from potential energy. If falling water is forced through ducts with rotators attached to them, the rotors will turn driving electric generators (Mc Gown 182). Tidal power works rather like a hydroelectric scheme, except that the dam is much bigger. A huge dam (called a "barrage") is built across a river estuary. When the tide goes in and out, the water flows through tunnels in the dam. The ebb and flow of the tides can be used to turn a turbine, or it can be used to push air through a pipe, which then turns a turbine. Large lock gates, like the ones used on canals, allow ships to pass. If one was built across the Severn Estuary, the tides at Weston-super-Mare would not go out nearly as far - there'd be water to play in for most of the time. But the Severn Estuary carries sewage and other wastes from many places (e.g. Bristol & Gloucester) out to sea. A tidal barrage would mean that this stuff would hang around Weston-super-Mare an awful lot longer! (www.geology.wisc.edu/~pbrown/g410/tidal/tidal.html)

Tidal energy generation

The thought of “If tidal energy could be used hundreds of years ago to create the energy needed to mill grain, then perhaps it could be used to create electricity that humans have become so dependant on” was actually put to work in France in 1967 when the first large-scale tidal scheme to produce electricity was constructed.

Generating electricity from tides is very similar to hydroelectric generation, except the tides flow in two directions rather than one. For tidal power, the most common generating system is the ebb generating system. In the scheme, a dam, or barrage is constructed across an estuary. The tidal basin is allowed to fill when the sluice gates are opened and high tide is in. The gates are then closed when the tide turns trapping the water behind the gates. Once low tide is reached, the gates are opened the water flows through the turbines located underneath the water generating electricity. The basic concept for this type of scheme is extremely similar to that used at the Eling Mill. The schematic below shows the basic concept used in an ebb generation scheme.

Ebb generating system with a bulb turbine (Energy Authority of NSW Tidal Power Fact Sheet)

In some cases, double effect turbines are used, which are able to generate electricity when then basin is filling. In this scheme, sluice gates located on either side of the turbine are opened, when the tidal basin is low, and the sea is at high tide level. Water will rush into the tidal basin, turning the turbines and generating electricity. This occurs until the water level on either side of the barrage is equal. At this point, the sluice gates are closed until the sea is at its low tide height. When this occurs, the gates are opened and water flows from the basin to the sea, generating electricity a second time.

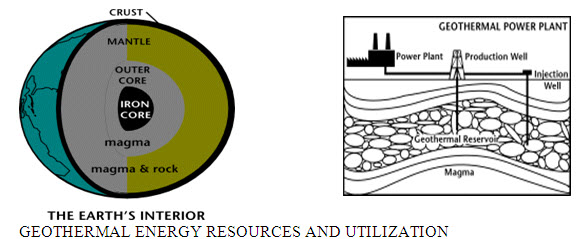

GEOTHERMAL

Geothermal Energy Potential in India

India has a geothermal power potential of 10,600MW, but the country is yet to see a single commissioned project that harnesses this technology. Though the capital cost for generating energy through geothermal is Rs80 million ($A2.46 million) to Rs100 million per MW, the operating cost is minimal.

ADVANTAGES OF GEOTHERMAL ENERGY

Geothermal energy is a domestic energy resource with cost, reliability and environmental advantages over conventional energy sources. It contributes both to energy supply, with electrical power generation and direct-heat uses.

For generation of electricity, hot water is brought from the underground reservoir to the surface through production wells, and is flashed to steam in special vessels by release of pressure. The steam is separated from the liquid and fed to a turbine engine, which turns a generator. Spent geothermal fluid is injected back into peripheral parts of the reservoir to help maintain reservoir pressure. In the absence of steam, heat from hot water is extracted through a secondary fluid and the high pressure vapour from the secondary fluid is utilized to run the turbine.

If the reservoir is to be used for direct-heat application, the geothermal water is usually fed to a heat exchanger and the heat thus extracted is used for home heating, greenhouse, vegetable drying and a wide variety of other small scale industries. Hot water at temperatures less than 120 o C can be used for this purpose. Further, the spent hot water, after generating electricity can also be used for direct application.

As a result of today's geothermal production, consumption of exhaustible fossil fuels is offset, along with the release of acid-rain and greenhouse gases that are caused by fossil-fuel use. Systems for use of geothermal energy have proven to be extremely reliable and flexible. Geothermal electric power plants are on line 97% of the time, whereas nuclear plants average only 65% and coal plants only 75% on-line time. Geothermal plants are modular, and can be installed in increments as needed. Because they are modular, they can be transported conveniently to any site. Both baseline and peaking power can be generated. Construction time can be as little as 6 months for plants in the range 0.5 to 10 MW and as little as 2 years for clusters of plants totaling 250 MW or more.

WORLD GEOTHERMAL ENERGY PRODUCTION

|

Country |

1990 (MW electricity installed) |

1999 (MW electricity installed) |

|

USA |

2775 |

2850 |

|

Philippines |

891 |

1848 |

|

Italy |

545 |

769 |

|

Mexico |

700 |

753 |

|

Indonesia |

145 |

590 |

|

Japan |

215 |

530 |

|

New Zealand |

283 |

345 |

|

Iceland |

45 |

140 |

|

Costa Rica |

0 |

120 |

|

El Salvador |

95 |

105 |

|

Nicaragua |

70 |

70 |

|

Kenya |

45 |

45 |

|

China |

19 |

32 |

|

Guatemala |

0 |

29 |

|

Turkey |

20 |

20.4 |

|

Totals installed electrical generating capacity |

5867 |

8246 |

Power Generation Technology

High Temperature Resources

High temperature geothermal reservoirs containing water and/or steam can provide steam to directly drive steam turbines and electrical generation plant. More recently developed binary power plant technologies enables more of the heat from the resource to be utilised for power generation. A combination of conventional flash and binary cycle technology is becoming increasingly popular.

High temperature resources commonly produce either steam, or a mixture of steam and water from the production wells. The steam and water is separated in a pressure vessel (Separator), with the steam piped to the power station where it drives one or more steam turbines to produce electric power. The separated geothermal water (brine) is either utilised in a binary cycle type plant to produce more power, or is disposed of back into the reservoir down deep (injection) wells. The following is a brief description of each of the technologies most commonly used to utilise high temperature resources for power generation.

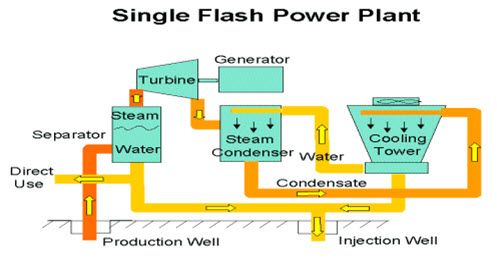

Flash Steam Power Plant

This is the most common type of geothermal power plant. The steam, once it has been separated from the water, is piped to the powerhouse where it is used to drive the steam turbine. The steam is condensed after leaving the turbine, creating a partial vacuum and thereby maximizing the power generated by the turbine-generator. The steam is usually condensed either in a direct contact condenser, or a heat exchanger type condenser. In a direct contact condenser the cooling water from the cooling tower is sprayed onto and mixes with the steam. The condensed steam then forms part of the cooling water circuit, and a substantial portion is subsequently evaporated and is dispersed into the atmosphere through the cooling tower. Excess cooling water called blow down is often disposed of in shallow injection wells. As an alternative to direct contact condensers shell and tube type condensers are sometimes used, as is shown in the schematic below. In this type of plant, the condensed steam does not come into contact with the cooling water, and is disposed of in injection wells.

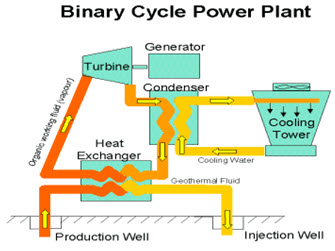

Binary Cycle Power Plants

In reservoirs where temperatures are typically less than 220o C. but greater than 100o C binary cycle plants are often utilised. The illustration (Fig. 4) shows the principal elements of this type of plant. The reservoir fluid (either steam or water or both) is passed through a heat exchanger which heats a secondary working fluid (organic) which has a boiling point lower than 100o C. This is typically an organic fluid such as Isopentane, which is vaporised and is used to drive the turbine. The organic fluid is then condensed in a similar manner to the steam in the flash power plant described above, except that a shell and tube type condenser rather than direct contact is used. The fluid in a binary plant is recycled back to the heat exchanger and forms a closed loop. The cooled reservoir fluid is again re-injected back into the reservoir.

Combined Cycle (Flash and Binary)

Combined Cycle power plants are a combination of conventional steam turbine technology and binary cycle technology. By combining both technologies, higher overall utilization efficiencies can be gained, as the conventional steam turbine is more efficient at generation of power from high temperature steam, and the binary cycle from the lower temperature separated water. In addition, by replacing the condenser-cooling tower cooling system in a conventional plant by a binary plant, the heat available from condensing the spent steam after it has left the steam turbine can be utilized to produce more power.