Site pages

Current course

Participants

General

MODULE 1. Overview of renewable energy sources

MODULE 2. Characterization of Biomass

MODULE 3. Thermochemical conversion Technology (TCCT)

MODULE 4. Biochemical conversion Technology-Biogas...

MODULE 5. Bio-fuels (BCCT)

MODULE 6. Solar Energy Conversion System (SECS)

MODULE 7. Hydro-Energy Conversion System (HECS)

MODULE 8. Wind Energy Conversion System (WECS)

MODULE 9. Ocean Energy Conversion System (OECS)

MODULE 10. Energy conservation in agriculture

LESSON 17. Bio-Diesel

Biodiesel production method-flowchart-components-byproducts-utilization

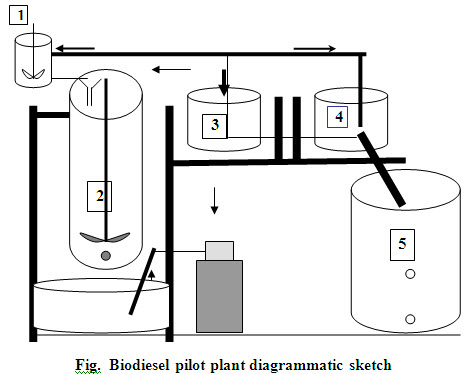

TNAU biodiesel pilot plant

For the esterification of Jatropha oil, alkaline-based catalyst is used in this plant. The Jatropha oil is blended with alcohol and catalyst mixture. The oil extracted from the seeds of Jatropha is mixed with methanol catalyst mixture at a proportion under a particular temperature. This solution is continuously stirred for two hours. During the above process, glycerol present in the solution separate out, which when settled can be separated out. For settling, three separate tanks are provided in the plant. After removing the glycerol, the liquid biodiesel is transferred to washing tank, where the fuel is washed twice and the purified biodiesel is obtained.

1. Mixing tank for chemical 2. Main reactor

3 & 4. Settling tanks 5. Washing tank

By using the above unit, about 250 litres of biodiesel could be produced in a day. The cost of the unit is approximately 1.5 lakhs. This could be reduced by appropriate substitutions in the existing plant. Depending upon the need, the size of the unit can be scaled up to get higher capacity.

Process flow chart

Mechanics of the transesterification process

-

Take 50 litres of Jatropha oil in the container and pump oil from inlet tank to biodiesel reactor by using inlet pump (10 minutes)

-

Switch ON for heater of biodiesel reactor

-

Take 20 per cent of methanol and 1 per cent of sodium hydroxide (by weight of oil) in the chemical mixing tank. Ensure that gate valve for chemical tank is in closed position before filling of methanol into tank

-

Switch ON for stirrer of chemical mixing tank (15 minutes) to produce the sodium methoxide solution

-

After reaching reaction temperature 60 deg. C, the sodium methoxide is send to biodiesel reactor by opening of gate valve and close the valve.

-

Switch ON for main stirrer of biodiesel reactor and reaction is continued for about 2 hours

-

After reaction time is completed, open the gate valve for glycerol settling tank and the biodiesel and glycerol mixer is send to the glycerol settling tank (by using storage switch)

-

Allow the biodiesel mixture in glycerol settling tanks for 12 hours

-

Before feeding of raw biodiesel, fill 100 litres of water in the washing tank

-

Remove the glycerol from settling tank and biodiesel is sent to washing tank by opening gate

-

Switch ON the aerator for 30 minutes. Allow the sample for 3 hours and remove the biodiesel from washing tank

-

Heat the biodiesel for 20 minutes to remove the moisture.

POST PRODUCTION PROCESS

Refining (Cleaning)

The esters recovered from the reaction mixture are refined to meet the requirements of ASTM D 6751-2. The topics include: biodiesel/glycerol separation, ester washing, ester drying, other ester treatments and additization.

Biodiesel/glycerol separation

The biodiesel /glycerol separation is typically the first step of product recovery in most biodiesel processes. The separation process is based on the facts that fatty acid alcohol esters and glycerol are sparingly mutually soluble, and that there is a significant difference in density between the ester and glycerol phases. The presence of methanol in one or both phases affects the solubility of ester in glycerol and glycerol in ester.

The biodiesel washing step is used to neutralize any residual catalyst, to remove any soaps formed during the esterification reaction and to remove residual free glycerol and methanol.

Ester drying is required to meet the stringent limits on the amount of water present in the final biodiesel product. In addition, there may be other treatments used to reduce color bodies in the fuel, remove sulfur and phosphorus from the fuel, or to remove glycerides.

Additization is the addition of materials that have a specific functionality that modifies one or more fuel properties. Examples include cloud point/pour point additives, antioxidants, or other stability enhancing agents.

Fatty acid alcohol esters have a density of about 0.88 gm/cc, while the glycerol phase has a density on the order of 1.05 gm/cc, or more. The glycerol density depends on the amount of methanol, water, and catalyst in the glycerol. This density difference is sufficient for the use of simple gravity separation techniques for two phases.

Any of the three categories of the equipments viz., Decanter system or Centrifuge System or Hydro cyclone can be used to separate the ester and glycerol phases.