Site pages

Current course

Participants

General

MODULE 1. Overview of renewable energy sources

MODULE 2. Characterization of Biomass

MODULE 3. Thermochemical conversion Technology (TCCT)

MODULE 4. Biochemical conversion Technology-Biogas...

MODULE 5. Bio-fuels (BCCT)

MODULE 6. Solar Energy Conversion System (SECS)

MODULE 7. Hydro-Energy Conversion System (HECS)

MODULE 8. Wind Energy Conversion System (WECS)

MODULE 9. Ocean Energy Conversion System (OECS)

MODULE 10. Energy conservation in agriculture

LESSON 29. Wind mill- water pumping

The energy needs of the agricultural sector have been on the rise with the introduction of improved farming technologies and increased mechanization. The electrical power needs of the agricultural sector have risen to almost 40 per cent of the total power consumption in the state. The heavy state subsidies, concessional and flat tariffs given to the sector for conventional electric power act as a disincentive for renewable energy source or energy conservation and along with the increasing rise in demand, strain the already taxed power situation in this country.

Wind pumping is a well-established technology that offers an alternative to diesel and electric pumpsets. Most wind pumps can operate under fairly low wind conditions (6-8 kmph) and are especially appropriate for the modest water needs of small farming establishments. Storing water is also cheaper than storing electricity. During low wind periods the owner can simply draw on the water that was pumped into the storage tank when the wind was ample.

Most mechanical wind machines use fan type blades, which can range from a minimum of 4 to a maximum of 24 blades to capture the wind energy, which is then transferred by a drive shaft to the pumping mechanism. Today gear type windmills are promoted under the National water pumping wind mill programme as they are easier for operation and maintenance.

Wind is a highly variable energy resource. The user cannot control its timing or intensity. A strong wind may cause the storage tank to over flow, while a weak wind might not provide enough water for the user’s needs. Effective use of the wind pump depends on a clear matching of demand and supply facilitated both by matching the design of the wind pump (its water output etc.,) to suit the user’s needs, and the user himself learning to use the wind pump and the stored water effectively.

In areas where electricity lines have not yet reached or where the supply is erratic and diesel supplies are expensive and unreliable, wind pumps have ensured water for man, animals and land.

The annual operation and maintenance cost of a wind pump in total averages at about Rs. 500-700. This is besides the oiling and moving parts (twice a month), changing the washers (between 1-3 years, depending on the use) and changing the oil in the gear box (once a year). Preventive maintenance is crucial to the smooth and regular working of the wind pumps, to check downtime.

In the coming years, research and development one going to play a pivotal role in the acceptance of the wind pump technology on a scale that can meet the requirement of large, agro-economic developing country like India. Problems to be tackled will primarily have to do with increasing water output and lessening maintenance headache.

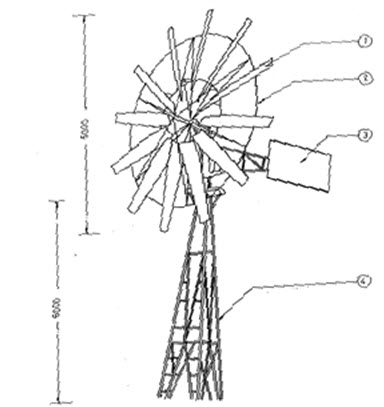

Wind mill for water pumping

1. Vane 2. Rotor 3. Tail 4. Tower

The reciprocating pump is fitted at 25 m. depth in a bore well. The vanes are reinforced with 25 x 25 x 8 mm. size L angles at the backside of the periphery for longevity.

Salient Features

The discharge rate at 14 to 25 km/h wind velocity is 3,000 to 4,750 litre/h.

This can be used for medium wind speed areas (10-14 km/h).