Site pages

Current course

Participants

General

Module 1. Tractor Mechanics

Module 2. Traction

Module 3. Introduction to Transmission System

Module 4. Clutch System

Module 5. Gear Box

Module 6. Differential and Final drive

Module 7. Brakes

Module 8. Steering system

Module 9. Hydraulics

Module 10. Power Transmission

Module 11. Human Factors

Lesson 13. Hydraulic drives

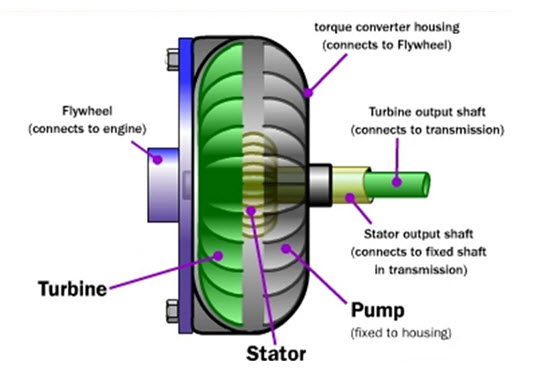

In case of automatic transmission, there is no clutch that engages or disengages the engine power to the transmission. This is done with the use of a hydraulic torque converter. This is also called a fluid coupling.

The main components of a torque converter are:

Pump

Turbine

Stator

Transmission fluid

The pump and the turbine are bowl shaped with fins on the inside. These are assembled facing each other with the transmission oil inside. The pump and the turbine are fitted to the flywheel in such a way that the pump is fixed to the flywheel and rotates along with the flywheel whenever the engine is turning. The turbine is fitted between the flywheel and the pump but is free to rotate of the flywheel or the pump.

The fins on the inside of the pump are given a direction in such a way that the when the pump rotates, the oil inside is imparted kinetic energy like in a centrifugal pump. When this oil goes into the turbine, it strikes the fins of the turbine in such a way that it transfers the kinetic energy to the turbine.

This turbine is connected to the out shaft which rotates along with the turbine, and serves as the input to the transmission. As the oil moves from the pump portion to the turbine component and it imparts its kinetic energy to the turbine, there is a change in direction of the oil. Now when this goes back to the pump side, the pump has to impart an additional force to change the direction of oil and increase the kinetic energy of this oil. This action regarding the changing the direction of the oil, leads to unnecessary wastage of energy.

For this reason a stator is provided. The stator is placed in the very center of the torque converter. Its job is to redirect the fluid returning from the turbine before it hits the pump again. This dramatically increases the efficiency of the torque converter.

The stator has a blade design that almost completely reverses the direction of the fluid. A one-way clutch connects the stator to a fixed shaft in the transmission. Because of this arrangement, the stator cannot spin with the fluid -- it can spin only in the opposite direction, forcing the fluid to change direction as it hits the stator blades. This helps in increasing the torque being output this effect only happens when the engine is turning much faster than the transmission.