Site pages

Current course

Participants

General

Module 1. Tractor Mechanics

Module 2. Traction

Module 3. Introduction to Transmission System

Module 4. Clutch System

Module 5. Gear Box

Module 6. Differential and Final drive

Module 7. Brakes

Module 8. Steering system

Module 9. Hydraulics

Module 10. Power Transmission

Module 11. Human Factors

Lesson 20. Brake System – necessity, working principle, functional components, brake lining material.

BRAKES

The braking system is an important system in the tractors used to slow down or stop the tractor motion. It is also used to prevent the tractor from moving when it is stationary. During field operations it helps in taking sharp turns by applying differential brakes on the two rear wheels.

The brakes use the financial force to reduce the motion of the wheels. Friction is used to convert the kinetic energy into heat.

The brake arrangement serves to intentionally offer resistance to the movement of the tractor. Most common are the friction brakes. These are essentially heat devices that change the kinetic energy of the moving vehicle into heat, by virtue of friction between a rotating component and a stationary component which are mechanically moved so that they come in contact with the rotating component. The stationary are lined with a hard wearing friction material. When this material is moved into contact with the rotating component, braking takes place.

Brake is used to stop or slow down the motion of a tractor. It is mounted on the driving axle and operated by two independent pedals. Each pedal can be operated independently to assist the turning of tractor during the fieldwork or locked together by means of a lock.

Principle of operation: Brake works on the principle of friction. When a moving clement is brought into contact with a stationary element, the motion of the moving element is affected. This is due to frictional force, which acts in opposite direction of the motion and converts the kinetic energy into heat energy.

Classification of brake: Brake can be classified as:

(1) Mechanical brake and

(2) Hydraulic brake.

Mechanical brake can be:

(a) Internal expanding shoe type

(b) External contracting shoe type and

(c) Disc type.

Internal expanding shoe type: Two brake shoes made of frictional material fitted on the inside of the brake drum are held away from the drum by means of springs. One end of each shoe is fulcrum whereas the other is free to move by the action of a cam which in turn applies force on the shoes. The movement of the cam is caused by the brake pedal through the linkage. The drum is mounted on the rear axle whereas the shoe assembly is stationary and mounted on the back plate.

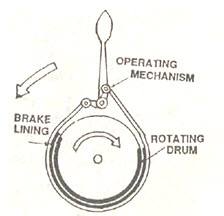

External contracting shoe type: This type of brake system is normally available on crawler tractors. The brake band directly surrounds the drum mounted on the drive axle. When the pedal is depressed, the band tightens the drum

Disc brake: Two actuating discs have holes drilled in each disc in which steel balls are placed. When the brake pedal is depressed, the links help to move the two discs in opposite directions. This brings the steel balls to shallow part of the holes drilled in the disc. As a result, the two discs are expanded and braking discs are pressed in between the discs and the stationary housing. The braking discs are directly mounted on the differential shaft, which ultimately transfers the traveling effect to the differential shaft.

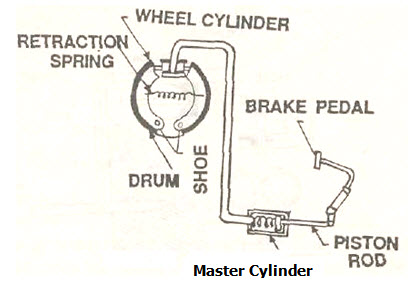

Hydraulic brake: Hydraulic brake system is based on the principle of pascal's law. The brake fluid, which is usually a mixture of glycerin and alcohol, is filled in the master cylinder. When the pedal is depressed, the piston of the master cylinder is forced into the cylinder and the entire system turns to a pressure system. Immediately, the piston of the wheel cylinder slides outward which moves the brake shoes to stop the rotating drum. When the pedal is released, the return spring of the master cylinder moves the piston back to its

Braking Efficiency:

High braking efficiency is required as on many occasions the brakes are required to stop the vehicle in emergency. However higher brake efficiency not only leads to stopping in a shorter time, may also cause injury to the driver operator due to high decelerating forces and dislodging of loads in the trolley. Higher braking efficiency also causes rapid wear of the brakes and there is more risk of losing control of the vehicle. Braking efficiencies of the order of 50-80% enable to stop within reasonable distance. However the stopping distance varies with the type of road conditions and condition of the tyres.

Braking distance generally refers to the distance a vehicle will travel from the point when the brakes are fully applied to when it comes to a complete stop. It is primarily affected by the original speed of the vehicle and the coefficient of friction between the tires and the road surface. Braking distance also includes the reaction time to when the driver feels the need to stop the vehicle and the response time