Site pages

Current course

Participants

General

Module 1. Introduction to by-products and waste ge...

Module 2. Waste management concepts

Module 3. Direct combustion of solid waste

Module 4. Thermo-chemical conversion of solid waste

Module 5. Bio-chemical conversion of solid waste

Module 6. Solid waste management

Module 7. Effluent treatment and disposal

Module 8. Presence of typical chemicals

Topic 9

Topic 10

Lesson 2.

Waste is inevitably produced in all human activities; and its volume is proportional to the resources consumed. Waste is generally thought of as something that is no longer needed by the original user and is subsequently discarded. The increased culture of consumerism within our societies has escalated the problem of waste because of the use of disposable goods. Processed food wastes constitute one of the largest fractions of municipal waste these days. Manufacturing processes operate under strict quality control which has resulted in the generation of large volumes of food and packaging waste.

Transferring food from the field to the plate involves a sophisticated production and supply chain, but for the purposes of waste production this can be simplified into three main steps: agriculture, food processors/manufacturers and the retail / commercial sector. Each of the sectors generates waste and wash water. Given the complexity of the food chain, environmental impacts can occur at various points in the chain, even for a single food product. It is therefore necessary to take a holistic systems-based approach to tackle the problem.

Waste characteristics

The quality and quantity of wastes produced depend on the type of food being processed. There are big differences from sector to sector, and even site to site: generalization is not only difficult, but could also be misleading. Food wastages levels are often inferred from mass balances. It is estimated that about 21% of food product at the farm gate is lost, much due to spoilage, and only about 7%, on an average, is lost during processing. From the data cited in it can be inferred that, although the percentage loss during food processing is low, wastage mass or volumes are very high. The wastes produced in any food industry depend mainly on the type of food being processed. Food processing operations produce many varied types of wastes that can be categorized into solid, liquid and gaseous wastes.

Solid wastes

Solid wastes emanating from food processing plants may include: the unnecessary leftover from the preliminary processing operations, residues generated as an integral part of processing, wastes resulting from processing inefficiencies, sludge produced from the treatment of wastewater, containers for the raw materials and finished products. In general, solid wastes are poorly characterized, both in terms of quality and quantity; and estimates of solid wastes are usually inferred from mass balances.

Liquid wastes

Wastewater from the processing industry is the main stream that is produced. It includes: wastewater resulting from using water as a coolant, water produced by different processing operations like washing, trimming, blanching and pasteurizing and a large amount of wastewater produced from cleaning equipment.

Gaseous wastes

The gaseous emissions from the food processing industry are mainly manifested in terms of emanating odors and, to a lesser extent, in terms of dust pollution. Other emissions include solvent vapors commonly described as volatile organic emissions and gases discharged by combustion of fuels. Even though the characteristics of food wastes can be discussed in terms of their physical states, it is necessary to note that solid wastes contain a substantial proportion of water, just as liquid wastes may contain a significant proportion of solids. It is therefore absolutely critical to note that food wastes are not only multi-component but also multiphase in nature.

Waste management

Waste management is the collection, transport, processing or disposal as well as, managing and monitoring of waste materials. The term usually relates to materials produced by human activity, and the process is generally undertaken to reduce their effect on health, the environment or aesthetics. Waste management is a distinct practice from resource recovery which focuses on delaying the rate of consumption of natural resources. All wastes materials, whether they are solid, liquid, gaseous or radioactive fall within the remit of waste management

Waste management concepts

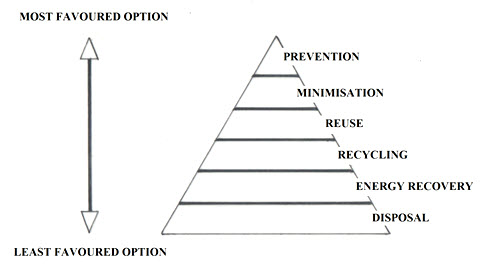

There are a number of concepts about waste management which vary in their usage between countries or regions. The primary objective in waste management is to completely prevent the production of waste all together, if possible (Faulstich and Schenkel, 1994; EC, 1975). Second, if waste must be roduced, then it is to be recycled. Entirely avoiding waste production or recycling food waste in the food industry is extremely difficult. Some of the most general, widely used concepts include:

- The waste hierarchy refers to the "3 R s" reduce, reuse and recycle, which classify waste management strategies according to their desirability in terms of waste minimization. The waste hierarchy remains the cornerstone of most waste minimization strategies. The aim of the waste hierarchy is to extract the maximum practical benefits from products and to generate the minimum amount of waste. The Rs are categories at the top of our disposal options. They include a variety of initiatives for disposing of discards. Generally, options lowest on the list are least desirable. However in Europe the waste hierarchy has five steps: reduce, reuse, recycle, recovery, and disposal. The aim of the waste hierarchy is to extract the maximum practical benefits from products and to generate the minimum amount of waste. Some waste management experts have recently incorporated an additional R: "Re-think", with the implied meaning that the present system may have fundamental flaws, and that a thoroughly effective system of waste management may need an entirely new way of looking at waste. The 3R’s of reduce, reuse and recycle have been considered to be a base of environmental awareness and a way of promoting ecological balance through conscious behaviour and choices. It is generally accepted that these patterns of behaviour and consumer choices will lead to savings in materials and energy which will benefit the environment.

- Source reduction involves efforts to reduce hazardous waste and other materials by modifying industrial production. Source reduction methods involve changes in manufacturing technology, raw material inputs, and product formulation. At times, the term "pollution prevention" may refer to source reduction.

- Another method of source reduction is to increase incentives for recycling. Many communities in the United States are implementing variable-rate pricing for waste disposal (also known as Pay As You Throw - PAYT) which has been effective in reducing the size of the municipal waste stream.

- Source reduction is typically measured by efficiencies and cutbacks in waste. Toxics use reduction is a more controversial approach to source reduction that targets and measures reductions in the upstream use of toxic materials. Toxics use reduction emphasizes the more preventive aspects of source reduction but, due to its emphasis on toxic chemical inputs, has been opposed more vigorously by chemical manufacturers.

Reduce

To buy less and use less. Incorporates common sense ideas like turning off the lights, rain barrels, and taking shorter showers, but also plays a part in composting/grass cycling (transportation energy is reduced), low-flow toilets, and programmable thermostats. Includes the terms Re-think, Recycle, Carpool, Efficient, and Environmental Footprint.

Reuse

Elements of the discarded item are used again. Initiatives include waste exchange, hand-me-downs, garage sales, quilting, travel mugs, and composting (nutrients). Includes the terms laundry, repair, regift and up cycle.

Recycle

Discards are separated into materials that may be incorporated into new products. This is different from Reuse in that energy is used to change the physical properties of the material. Initiatives include Composting, Beverage Container Deposits and buying products with a high content of post-consumer material. Within recycling there is distinction between two types:

The rest of the hierarchy

The Rs are not the only disposal options:

Generate

Capturing useful material for waste to energy programs. Which includes methane collection, gasification, and digestion, and the term recover.

Incinerate

High temperature destruction of material. Differs from gasification in that oxygen is used; differs from burning in that high temperatures consume material efficiently and emissions are controlled.

Devastate

To discard into the natural environment, or to "trash" the planet. Includes Litter, Landfill, Burn Barrels, Unnecessary Vehicle Idling, and Dumping discards onto land or into water

Polluter pays principle

The Polluter Pays Principle is a principle where the polluting party pays for the impact caused to the environment. With respect to waste management, this generally refers to the requirement for a waste generator to pay for appropriate disposal of the unrecoverable material.

The utilization and disposal of product specific waste is difficult for the following reasons (Werschnitzky et al., 1985; Russ et al., 1997; Russ and Meyer-Pittroff, 2004):

Biological stability and the potential growth of pathogens

Many types of waste material either already contain large numbers of microbes and/or will be altered quickly through microbial activity. If regulations concerning infectious disease are not properly observed, then hygienically unacceptable conditions can arise, e.g., through maggots or moulds. The breakdown of protein is always characterized by the generation of strong odours.

High water content

The water content of meat and vegetable waste lies between 70 and 95% by mass. High water content increases transport costs of the waste. Mechanically removing the water through use of a press can lead to further problems with waste water disposal, due to the high level of organic material in the water.

Rapid autoxidation

Waste with a high fat content is susceptible to oxidation, which leads to the release of foul-smelling fatty acids.

Changes due to enzymatic activity

In many types of waste arising from vegetables and fruits, enzymes are still active, which accelerate or intensify the reactions involved in spoilage.

Effluent treatment

Effluent is an out-flowing of water or gas from a natural body of water, or from a human-made structure. Effluent is defined as “wastewater - treated or untreated - that flows out of a treatment plant, sewer, or industrial outfall. Generally refers to wastes discharged into surface waters”. The Oxford English Dictionary defines effluent as “liquid waste or sewage discharged into a river or the sea”. Effluent in the artificial sense is in general considered to be water pollution, such as the outflow from a sewage treatment facility or the wastewater discharge from industrial facilities

The nature of wastewater includes physical, chemical, and biological characteristics which depend on the water usage in the community, the industrial and commercial contributions, weather, and infiltration/inflow. It is 99.94 percent water by weight (Water Pollution Control Federation 1980). The remaining 0.06 percent is material dissolved or suspended in the water. The dissolved and suspended solids in wastewater contain organic and inorganic material. Organic matter may include carbohydrates, fats, oils, grease, surfactants, proteins, pesticides and agricultural chemicals, volatile organic compounds, and other toxic chemicals. Inorganic matter may cover heavy metals, nutrients (nitrogen and phosphorus), pH, alkalinity, chlorides, sulfur, and other inorganic pollutants. Gases such as carbon dioxide, nitrogen, oxygen, hydrogen sulfide, and methane may be present in wastewater (Lee and Lin, 2000). Wastewaters are normally treated by a combination of physical-chemical and biological operations. However, it is possible to treat waste waters solely with physical-chemical methods

Wastewater treatment is a series of steps. Each of the steps can be accomplished using one or more treatment processes or types of equipment. The major categories of treatment steps are:

1. Preliminary treatment

The purpose of preliminary treatment is to protect plant equipment by removing these materials that could cause clogs, jams, or excessive wear to plant machinery. In addition, the removal of various materials at the beginning of the treatment process saves valuable space within the treatment plant’ Preliminary treatment may include many different processes. Each is designed to remove a specific type of material — a potential problem for the treatment process. Processes include: wastewater collections (influent pumping, screening, shredding, grit removal, flow measurement, pre-aeration, chemical addition, and flow equalization).

2. Primary treatment

The purpose of primary treatment (primary sedimentation or primary clarification) is to remove settle able organic and floatable solids. Normally, each primary clarification unit can be expected to remove 90 to 95% settle able solids, 40 to 60% TSS, and 25 to 35% BOD. Primary treatment reduces the velocity of the wastewater through a clarifier to approximately 1 to 2 ft/min, so that settling and floatation can take place. Slowing the flow enhances removal of suspended solids in wastewater. Primary settling tanks remove floated grease and scum, remove the settled sludge solids, Floating material (mostly grease and oil) is collected by a surface skimmer

3. Secondary treatment

Secondary treatment refers to those treatment processes that use biological processes to convert dissolved, suspended, and colloidal organic wastes to more stable solids that can either be removed by settling or discharged to the environment without causing harm. There are three commonly used approaches, and all take advantage of the ability of microorganisms to convert organic wastes (via biological treatment) into stabilized, low-energy compounds. The trickling filter (a bed of coarse media, usually rocks or plastic, covered with microorganisms ) and the activated sludge process, sequentially follow normal primary treatment. The third, ponds (oxidation ponds or lagoons), can provide equivalent results without preliminary treatment.

4. Disinfection

Removes microorganisms to eliminate or reduce the possibility of disease when the flow is discharged. Like drinking water, liquid wastewater effluent is disinfected. Unlike drinking water, wastewater effluent is disinfected not to directly (direct end-of-pipe connection) protects a drinking water supply, but instead is treated to protect public health in general. This is particularly important when the secondary effluent is discharged into a body of water used for swimming or for a downstream water supply.