Site pages

Current course

Participants

General

Module 1. Introduction to by-products and waste ge...

Module 2. Waste management concepts

Module 3. Direct combustion of solid waste

Module 4. Thermo-chemical conversion of solid waste

Module 5. Bio-chemical conversion of solid waste

Module 6. Solid waste management

Module 7. Effluent treatment and disposal

Module 8. Presence of typical chemicals

Topic 9

Topic 10

Lesson 9.

Food industries produce a substantial amount of pollution especially in the form of solids. So solid waste management is very important for industrial growth and environmental concerns. The main impact of solid pollutants is

-

Unnecessary use of land

-

Spread of diseases

-

Contamination of ground water

The management of industrial waste is comparatively easy as compared to municipal waste because of uniformly of the waste. The quantity and type of waste from agro-processing industry varies from unit to unit. The total quantity of solid waste generation is approx 50%of the quantity being processed. At present these waste are either dumped or sold as animal feed. The organic waste generated from various foods, sugar, coffee etc. have potential for bio-methanation.

The various methods of disposal are:

Landfills

Incineration

Compositing etc.

These methods are capable of degrade concentrated and difficult substrates like plant residues, animal waste, food industry wastes etc each method is having its advantage and disadvantages.

The environmental act 1995 states the following objectives for the treatment of wastes.

-

It should be ensured that waste is recovered or disposed off without endangering human health and without using methods which could harm the environment.

-

Best available technology at low cost should be used.

-

Ensure self-sufficiency in waste disposal.

-

The recovery of waste by means of recycling, re-use or reclamation and the use of waste as a source of energy must be encouraged.

Landfills

Landfills are primarily used for waste disposal, allowing nature to take its course. During the process of degradation, end volume and toxicity of wastes is used. The processes of degradation of organic bioactive waste in landfills involve not only biological processes, but also interrelated physical and chemical processes. The organic components of the waste are degraded by m/o’s in the landfills. The organic component could be protein, carbohydrates, lipids or fats. Carbohydrates are by for the major component of biogradable waste and include cellulose, starch and sugars. Proteins are large complex organic material composed of hundreds or thousands of amino-acid groups.

Lipids or facts are materials containing fatty acids. So landfill consists of 5 main steps

Hydrolysis/ aerobic degradation

Hydrolysis and fermentation

Acetogenesis

Methanogenesis

Oxidation

There are various factors which influence the degradation of the waste. These are

Site characteristics

Waste characteristics

Moisture content of waste

Temperature

Acidity

The modern site is seen in this content as a ‘bioreactor’ used to stabilize waste and produce landfill gas for energy recovery. The amount of landfill gas generated throughout the lifetime of the landfill site as highly variable (i.e 39-500 m3/tone).

Landfills are not very desired disposal method because of following regulations:

Stringent environmental regulations concerning air quality.

Around water contamination.

Decreasing availability of land.

The methods followed in India are not keeping with modern practices of sanitary landfilling. The wastes are largely dumped in low lying areas which are prone to flooding.

Incineration

An alternative to landfills is incineration i.e waste containing combustible material is incinerated or combusted. It is the oxidation of the combustible material in the waste to produce heat, water vapour, nitrogen, carbon dioxide and oxygen. Depending upon the composition of waste, other emission may be formed like carbon monoxide, hydrogen chloride, hydrogen fluoride, nitrogen oxides, sulfur dioxide, volatile organic carbon, dioxins and furns, polychlorinated biphenyls, heavy metals. Incineration is a treatment route which can be applied to a wide variety of waste.

Advantages of incineration over landfill

It can be carried out near point of waste collection.

The waste is reduced to a biologically sterile ash product.

It produces no methane unlike landfill

Waste incineration can be used as a low cost source of energy.

The bottom ash residues can be used for material recovery or secondary aggregates in construction.

It is the best practicable environmental option for hazardous wastes.

Disadvantages of incineration

Much higher costs and longer pay-back periods.

Lack of flexibility

Removal of paper and plastics for recycling may reduce the overall calorific value.

Emitted levels may still have an adverse effect on health.

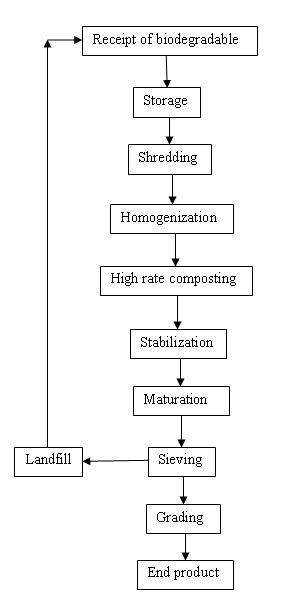

Compositing

Compositing is the aerobic rather than anaerobic, biological degradation of organic waste such as garden and food waste.

It is relatively fast biodegradation process, taking typically about 4-6 weeks to reach a stabilized product.

The main factors influencing composting are

Suitable oxygen

Temperature (30-35°C)

Moisture content 50-60%

pH range 5.5-8

CN ratio of material 25:1

Size range of waste material

During compositing organic matter is placed in piles that allow ventilation and the matter is stabilized by natural biological processes.

The process designs used in composting are

Aerated static pile composting

Mechanically agitated in-vessel composting

Windrow composting

1. Aerated static pile composting

Compost is formed into piles and aerated with blowers or vaccum pumps. The aerated static pile method of composting was developed in the mid-1970s to reduce land area requirements and to resolve other problems associated with the turned windrow method.

2. Mechanically agitated in-vessel composting

Compost is placed in a reactor vessel where it is mixed and aerated. Two basic types of reactors are used in vessel composting:

Vertical flow reactors:-

Horizontal or inclined reactors.

In vertical flow reactors the mixture is fed in at the top of the reactor on either a continous, intermittent or batch basis and can be agitated on its moving down the teactor to facilitate oxygenation. In some cases, the mixture is cycled through the reactor more than once. Horizontal reactors are force-aerated drums, fed continuously or intermittently with mixture. The mixture is thoroughly agitated with constant rotation of the drum. Inclined reactors are binstructures which are continuously or intermittently fed with mixture. In most cases, both forced aeration and mechanical agitation of the mixture is simultaneously, employed.

3. Windrow composting

Compost is placed in long piles known as windrows and periodically mixed with means of mobile equipment. Moisture, pH, temperature and contaminant concentrations are monitored. At the completion of the composting period, the windrows are disassembled and the compost is taken to the final disposal area. Windrow compositing is usually considered to be the most cost-effective composting alternative.

Vermin composting

The use of compost can contribute to the maintenance and improvement of soil fertility. Composting is a method of organic fertilization used in agriculture and gardening. Worm compost (also known as vermin compost, from “vermin”, the Latin for “worm”) is an especially high-grade and nutrient-rich fertilizer. Many tea and coffee growers keep small herds of cattle for extra income and use the dung produced as feed substrate for worm composting. The nutrient-rich worm compost is then used as fertilizer on the tea and coffee plantations, and increases in harvest yields. Vermin culture can be practiced even on a small scale, and easily be integrated into any agricultural system. For example, the waste from the crops currently being produced and processed (e. g. coffee pulp, or cuttings from shade trees in tea gardens). Vegetable waste has a more complex structure and a higher C/N ratio than cattle slurry. Besides this, micro-organisms can pre-digest it, thereby ensuring good aeration. Worm humus is a fertilizer suitable for all types of crops.

The humus can be harvested within as little as 2 – 5 months after start-up. However, the conversion period and the worms’ rate of reproduction always depend on the source material used, the worms’ living conditions (humidity, temperature) and how well the composting is managed.

Worm compost is one of the highest-grade and most nutrient-rich natural fertilisers in the world. Its soil conditioning properties and plant-strengthening effect encourage the growth and yield of the plants.

Characteristics

-

similar to the soil found in deciduous woodlands and mixed forests

-

black, odourless and crumbly substrate

-

balanced nutritional composition for plants

-

it contains an above-average number of micro-organisms which revitalise the soil.

-

loose yet stable soil structure (clay-humus complexes)

-

absolutely free from all types of synthetic chemical additives

Conversion processes

-

Accelerated conversion of organic waste matter by micro-organisms (bacteria, fungi) and by compost worms

-

The worms coat the organic material with their mucous excretions which contain micro-organisms (bacteria, fungi etc.) --> microbial predecomposition

-

The worms convert the pre-fermented composting material into worm humus, along with mineral substances

-

Worm humus is high in micro-organisms, enzymes and nutrients --> ideal supplier of nutrients bonded in clay-humus complexes, good plant availability

-

Cold composting (at temperatures below 50°C)

Plant nutritionists’ encouragement of soil fertility

-

Worm humus acts as an “appetiser” for plants, increasing their capacity to absorb water and nutrients

-

Earthworm humus contains the essential nutrients of nitrogen (N), phosphor (P) and potash (K) in much larger quantities than are present in the soil or in comparable compost. This makes it richer than mature manure or garden compost

-

During the course of composting, the ratio shifts in favour of N

(The C/N ratio of mature compost should be below 20. The higher the proportion of nitrogen in compost (primarily organically bonded nitrate and ammonium, the better, this complex process is performed by the worm in its gastrointestinal tract.)

Minimisation of solid waste with low toxicity and containing heavy metals

The worms are capable of processing of waste. This means they can be used to detoxify soils contaminated with solid waste, pesticides or heavy metals from industrial or agricultural waste. Worm enzymes and microbes in the worm humus can also degrade toxic substances. The toxicity level of worms should not be too high. To avoid these accumulated pollutants being passed on, the worm should be removed from the system. when the “contaminated” worm dies, everything will be go back into the soil. If the worm is used as a source of protein rich fodder, then the heavy metals will accumulate in the food chain.

Eisenia fetida

The most frequently used species of compost worm is the red wiggler (Eisenia fetida), which is naturally predisposed towards high rates of conversion and reproduction. it (grow to a length of 6 – 13 cm on average. They are reddish in colour, with yellowish rings. In threatening situations they exude a foul-smelling mucous, which is the reason for the name of this species: “fetida” means stinky.

Transformation of the organic material:

-

Between half and the whole of the equivalent of its body mass a day (depending on conditions: climate, food supply)

-

Under perfect conditions: 3,500 worms (approx. 1 kg) devour 1 kg kitchen waste a day

-

200 - 300 worms can convert a volume of 1 m² and 20 cm depth into worm humus within 60 days

-

Of 100% source material, 15% is what remains in the form of worm compost

Feed

Compost worms, which have a huge appetite, feed on almost anything from vegetable or animal sources. However, Eisenia fetida is particularly partial to cattle excrement. Therefor, cattle manure is the most commonly used source material for worm composting. However, green and nutrient-rich vegetable waste is also composted. Generally speaking, a wide range of source materials is suitable as worm fodder. However, the waste used should be from organic agricultural sources. it is said that, the finer the material offered to worms the faster its conversion. The compost should remain fairly constant throughout the composting period.

Source material for the fodder

- Animal excrement from

- cattle

- horses

- sheep

- pigs

- poultry

- goats

- hares

- donkeys

- Vegetable waste

- hay

- grass

- weeds

- leaves

- foliage, for example from tea or coffee trees (chopped small)

- cereals

- coffee pulp

- bean pods

- banana and orange peelings

- forest soil, ash

Nutritional balance in feed

The nitrogen content should not be too high. The worms then try to escape, and those which are not fast enough die. Fresh cattle manure must be pre-fermented. It must be moistened in a separate bed, built on a slight slope. If 2 – 3 drops appear when it is squeezed, the manure can be added to the worm bed.

Feeding process

-

At regular intervals of 10 – 30 days

-

Manually or automatically

Various worm composting methods

Most worm composting methods are relatively simple and require little effort.

There are various methods:-

tray stacks, windrows, compost heaps and bins, complete recycling systems, containers and box systems. Sometimes a simple wooden chest is suffi-cient.

Size of the worm compost heap

Most compost heaps are 1 – 2 m wide, 30 – 50 cm high, and can be as long as desired. Since Eisenia fetida is an epigeic species, i. e. a surface dweller which works in the upper layers of the soil, the compost should not be over 60 cm deep.

Location of worm compost heaps

The compost heaps can be distributed between rows of trees, or housed in shelters.

Climate

The Eisenia fetida can tolerate temperatures between 0 - 30°C and is therefore well suited to locations in the open air. To ensure that the earthworm bed does not get too hot, shade trees or a roof should protect it from direct sunshine. Fresh manure must first be prefermented. The humus should not be too moist as it can otherwise lead to an infection of the female reproduction organs. (Test by squeezing it. No more than 5 drops of liquid should come out of a handful.) In order to obtain constantly high rates of yield and reproduction, the following general conditions should be maintained by making adjustments to the processes:

Temperature 20°C - 25°C (ideally)

Humidity 80%

Sufficient oxygen (loose soil, to guarantee aerobic conditions)

pH-value 7.5 – 8.0 (ideal), 5.0 - 8.4 (tolerance value) --> Acidic pH-value can be compensated by adding calcium carbonate

Construction of a worm farm

Stage 1: Bedding

To create a perfect climate, a “worm bed” is made by using coarse materials such as shredded twigs, coconut fibre, mulch or wood shavings/sawdust as a basis, varying ac-cording to what is available locally. All the components should have been produced organically.

Properties of the worm bed:

Protection from extreme fluctuations in temperature

Guarantees well-balanced humidity and aeration

Stage 2: Feed

The next step is to cover the worm bed with a layer of feed matter consisting of vegetable waste and manure.

Stage 3: Introducing the worms

The worms are added to the compost heap in batches.

Stage 4: Watering the worm compost

The amount of water needed depends on the climate (temperature, evaporation).

Stage 5: Cover the compost heap

In order to protect the worm population from predators such as birds, rats, snakes, cock-roaches and ants, but also from heavy rains, the compost heap needs to be covered. Here, the most suitable materials are:

Banana leaves

Polyethylene foil

Wood

Bamboo

Bbricks

Corrugated sheeting

Palm leaves

Stage 6: Monitoring the worm compost

The compost heap should be checked once a week

Harvesting the vermin compost

The compost can be harvested in about 2 – 5 months.

There are various ways to go about it:

If the compost heap takes the form of a windrow, the source material is introduced to one end of the windrow and added to continuously. Care should be taken that the new material added is in contact with the old substrate. The compost worms move over to the fresh substrate and continue conversion there. The older material can then be harvested and, if necessary, left to mature.

If the worm bed is constructed in layers, this should consist of several trays. The bottom tray (collecting pan) serves as a reservoir for the liquid seepage. The bottom of the working trays designed to hold the compost material should have holes or slits in them large enough for the worms to pass through. They are placed on the collecting pan. The first working tray is now filled with the source material: at the bottom comes a layer of coarse material (e. g. wood shavings), and on top of this a layer of finer material (leaves and manure). As soon as most of the material has been converted to compost, the next working tray is placed on top of it, so that the bottom of this tray is in contact with the material below, and filled with fresh material. Once the worms have migrated up into the new tray, the worm compost can be removed from the lower tray. If the compost bed is on a slight incline and not filled completely, then the finished compost is sieved into the upper part. Alternatively, the upper humus layer can be removed carefully by hand, and the worms then retreat downwards.

In most cases the farms and co-operatives use the worm compost for their own fields and gardens, but there are plants which sell the worm humus

Storage of vermin compost

The worm humus is slightly moistened and then stored in sacks in the shade. The humus is stored for up to one month before being applied to the soil.

vermin wash

The seepage (vermiwash) drained from the worm bed is especially valued, and is used in diluted form as foliar spray. This concentrated liquid fertiliser contains valuable amino and silicic acids.

A method to prepare vermin wash

If vermin compost, when finished, is diluted with water, this becomes the liquid “vermin wash” (“humus liquido”). A decoction is made of one part vermin compost to ten or twenty parts water, and left to stand for between 15 and 24 hours. There are then two procedures to choose from: either an air pump is used to pump air into the concoction throughout this period, or no air is pumped in (a method which, however, since anaerobic, is suspected of producing substances harmful to plants).

Application of vermin wash

The vermiwash is either poured onto the soil or sprayed on the leaves. This strengthens the epidermis of the leaves and reduces damage by aphids and penetrating fungal spores. It is also possible to use vermiwash in drip irrigation or other standard methods of irrigation, as it reducing the amount of work required.

Vermin culture is more sensitive than other composting methods

-

Vermicompost is susceptible to extreme weather conditions such as frost, heavy rainfall, drought and overheating.

-

Anaerobic conditions (due to compaction) can lead to lack of oxygen.

-

Every stage, from construction to feeding and irrigation, must be controlled and monitored.