Site pages

Current course

Participants

General

Module 1. Introduction to by-products and waste ge...

Module 2. Waste management concepts

Module 3. Direct combustion of solid waste

Module 4. Thermo-chemical conversion of solid waste

Module 5. Bio-chemical conversion of solid waste

Module 6. Solid waste management

Module 7. Effluent treatment and disposal

Module 8. Presence of typical chemicals

Topic 9

Topic 10

Lesson 13.

Oxidation ditches (oxidation ponds) sludge process, rotating biological contractors and aerated lagoons are different types of secondary treatment of waste water. All these systems depend upon the growth of various microbes which degrade the organic matter present in the waste water. Therefore, also called as biological treatment.

Oxidation Pond

The basic biological phenomena in the treatment of waste in aqueous environment is as follows:

-

The degradable organic compounds (carbohydrates, proteins and fats etc.) are broken down by aerobic microorganisms mainly by bacteria and to some extent by fungi. This results in an effluent production which is having very less organic matter.

-

The materials which are very difficult to digest form a sludge, which is removed from time to time and can also be treated separately.

It is an artificial pond in which waste water can be retained for a sufficient time to satisfy the BOD ( Biological Oxygen Demand) and make the waste non-putrescible. The purifying action of oxidation pond is due to unique relationship between algae and bacteria in shallow ponds.

Bacteria metabolize organic matter and releases nutrients like Nitrogen, Phosphorous and CO2. Algae use these compounds along with energy from sunlight for synthesis of organic matter and releases O2 into solution. O2 released by algae is taken by bacteria, thus closing the cycle. This type of relation is called Symbiosis. It is common among living organisms in the pond. Besides these, other micro-organisms like protozoa, rotifers etc. also live in those waters and feed on algae and bacteria.

- Oxidation ponds act as facultative ponds because of shallow depth (< 2m). As the raw waste effluent without primary treatment enters the pond, the organic solid settles to the bottom and decompose anaerobically forming a sludge zone at the bottom and produce intermediate products. These products are acted upon by facultative and aerobic bacteria and converted into stabilized nutrient form. O2 is added to the waste water in the pond by wind action at the surface and from day light metabolism of algae.

- It is Highly efficient system as BOD removal is 90% and Coli form removal is > 99%

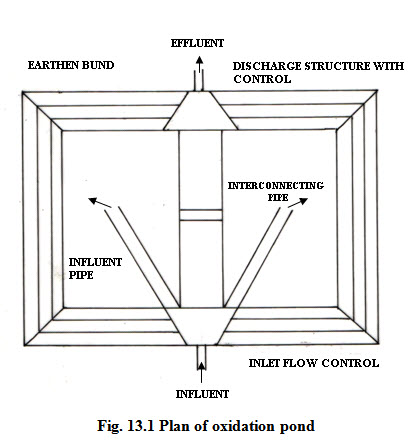

- Oxidation ponds are rectangular in shape (L/B = 2-3/1) having side slopes (1:1.5) and are constructed by building embankments of earth (Fig.13.1). They are of shallow depth usually 0.9-1.5m and as such effective in permitting penetration of sunlight to all parts of the waste water encouraging algal growth. Influents is applied in the middle of pond and allowed to be spread by the action of wind currents which prevents any odour nuisance due to concentration.

- Usually more than 1 in numbers are operated either in parallel or series.

- Operating ponds in series generally causes increased BOD reduction by preventing short-circuiting.

- Parallel operation is desirable to distribute the raw BOD load and avoid potential odor problems.

Oxidation ponds are suitable in case of small cities where large land areas are easily available and cheap. Also, in tropical countries where dry climate and warm temperature is prevalent

Advantages of oxidation ponds

- Low cost

- Quickness of construction

- Easy maintenance

- High efficiency of BOD removal

Disadvantages of oxidation ponds

- Nuisance due to mosquito breeding and odours.

Oxidation ditch

It is a modified form of activated sludge process (extended aeration type)

- It is highly efficient involving simple waste treatment

- Comparable in performance with the oxidation pond.

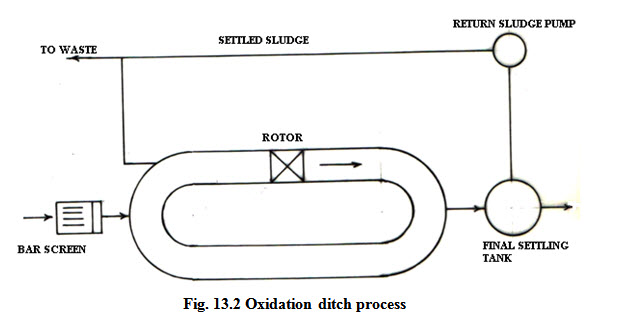

The process involves a single unit treatment in an endless channel equipped with a special type of rotor which serves the dual purpose of oxygenation and circulation.

- The ditch comprises of a trapezoidal cross-section of relatively shallow depth (0.9-1.5m) forming a continuous circuit.

- There is normally no primary tank and raw waste water passes directly through a bar screen to the ditch.

- Oxidation ditch forms the aeration basin where raw waste water is mixed with active organisms in ditch

- Cage rotor entrains the necessary O2 into the liquid and keeps the contents of the ditch mixed and moving.

- Physical cum biological process occurs where a small portion of the organic matter under goes direct chemical oxidation while bulk of organic matter is stabilized by biochemical activities of micro-organisms.

- The mixed liquor in the ditch flows to the clarifier for separation. The clarified liquid passes over the effluent well for disposal into receiving streams, while the settled sludge from the bottom of clarifier is removed by pumping and returned to the ditch for undergoing treatment.

- Detention period upto 24 hrs and is designed to carry mixed liquor suspended solid concentration of 3000-8000 mg/l with minimum circulation speed of 25 cm per second in the ditch.

- The plant can be operated continuously or intermittently.

- They can treat waste efficiently having BOD as high as 8000 mg/l

- This process has been used to treat domestic as well as industrial waste.

Activated sludge process

This is an aerobic breakdown of raw waste water. It is most widely used for treating waste water. Its main features are as follows:

a) It uses a complex population of micro-organisms (bacteria & protozoa)

b) This community of microorganisms has to cope with an uncontrollably diverse range of organic and inorganic compounds some of which may be toxic to the microbes.

c) The microbes occur in discreet aggregates known as flocs which are maintained in suspension in the aeration tank by

Mechanical agitation

Aeration

By mixing action of bubbles from submerged aeration systems.

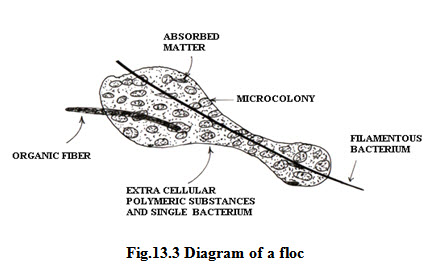

Flocs consist of bacterial cells, extracellular polymeric substances and adsorbed organic matter. These are highly variable in morphology, typically 40-400 µm in size and are not easy to break apart.

d) The flocs must have good settling properties so that separation of biomass of microbes and liquid phases occurs efficiently and rapidly in the clarifier. Sometimes proper separation is not achieved giving rise to problems of bulking and foaming.

e) Some of the settled biomass is recycled as returned activated sludge or RAS to inoculate the incoming raw waste water because it contains a community of organisms adapted to the incoming waste water.

f) The solid undigested sludge may be further treated into economically valuable products.

Advantages of activated sludge process

- Efficiency

- Economy of space

- Versatility

Modifications of activated sludge setup:

1. Conventional activated sludge set up

The basic components of the conventional systems are aeration tank and a sedimentation tank. Before raw waste water enters the aeration tank, it is mixed with a portion of the sludge from the sedimentation tank. The content of raw water are therefore broken down by organisms already adapted to the environment of the aeration tank. The incoming organisms from the sludge exits in small flocs. It is the introduction of already adapted flocs of microbes that gave rise to the name activated sludge. Usually, 25-50% of the flow through the plant is drawn off from the sedimentation tank.

2. Tapered aeration

In this, aeration is heaviest at the point of entry of waste water and diminishes towards distal end. The reason behind this is that concentration of organic matter is heavy at entry point where mixture of raw waste and returned sludge enters the aeration tank. The diminishing aeration may be made directly into the main aeration tank or a series of tanks with diminishing aeration may be set up.

3. Step aeration

Here feed is introduced at several equally spaced points along with length of the tank thus creating more uniform demand in the tank. The aeration may be done in a series of tanks just like tapered aeration.

4. Contact stabilization

This is used when the waste water has a high proportion of colloidal material. The colloid rich waste water is allowed contact with sludge for a short period of 1- 1.5 hrs in a contact basin which is aerated. After settlement in a sludge separation tank, part of the sludge is removed and part is recycled into an aeration tank where it is mixed with the incoming waste water.

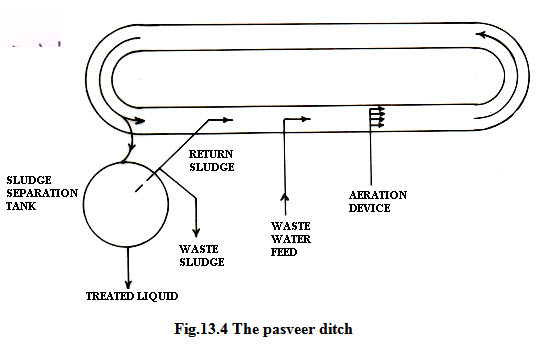

5. The pasveer ditch

This consists of a stadium shaped shallow (about 3”) ditch in which continuous flow and oxygenation are provided by mechanical devices. It is essentially the conventional activated sludge system in which material is circulated in ditch rather than in pipes (Fig.13.4).

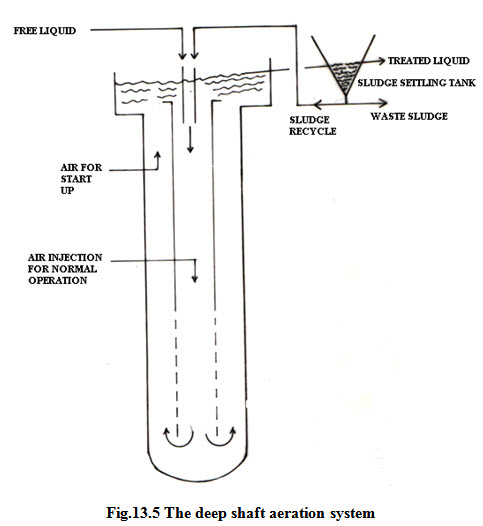

6. The deep shaft process

This system is developed by Agricultural Division of Imperial Chemical Industries (ICI) UK. It consists of an outer steel lined concrete shaft measuring 300 ft or more and is installed into the ground. Waste water and sludge recycle are injected down a inner steel tube. Compressed air is injected at a position along the centre shaft deep enough to ensure that the hydrostatic weight of the water above the point of injection is high enough to force air bubbles downwards and prevent coming upwards. The demand air lower down the shaft providing O2 for the aerobic breakdown of wastes. The water rises in the outer section of the shaft (Fig.13.5).

Advantages of the deep shaft process

Greater rapidity in reducing BOD

50% reduction in sludge

Space required is less

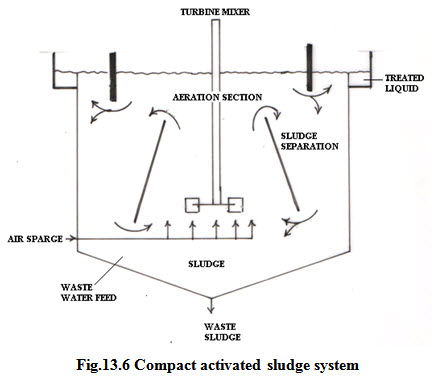

7. Enclosed tank systems and other compact system

Since breakdown of waste in aerobic biological treatment is brought about by aerobic microorganism, efficiency is increased by the use of O2/oxygen enriched air. Enclosed tank in which the wastewater is completely mixed with the help of agitators, are used for aeration. Sludge from sedimentation tank is returned to the enclosed tank along with raw water.

Advantages

Absence (or greatly reduced) obnoxious smell from exhaust gases

Increased efficiency of waste stabilization.

This system is widely used in industries the world over.

Compact activated sludge system

This system does not have a separate sedimentation tank. Instead sludge separation and aerobic breakdown occurs in a single tank.

Advantage: Economy of space

Microbes involved in Activated Sludge Process (ASP)

Mainly bacteria and ciliates (Protozoa). Zooglea ramigera (slime forming), Pseudomonas, Achromobacter, Flavobacteria etc.

Efficiency of system is determined by reduction in BOD. In conventional activated sludge plants, the contact time is approximately 10 hrs, after which 90-95% BOD is removed. When contact time is less, BOD removal is 60-70% and sludge produced is more. With longer contact time, says several days, BOD reduction is over 99%.

Aerated lagoons

Aerated lagoons are also called suspended growth aerated lagoons. They are relatively shallow basins made in soil and are provided with mechanical aerators fixed on plateforms. These aerators provide O2 for the biological treatment of waste water which ultimately stabilizes the organic matter.

Waste water after undergoing primary treatment through screens enters the lagoon and after biological pretreatment leaves from other side.

Lagoons are of two types

Facultative lagoons

Aerobic lagoons

Facultative lagoons

Here some solids settle down on the surface of the lagoon and rest may leave with effluent. The lower part of lagoon is anaerobic while upper is aerobic. So, these are called facultative.

Aerobic lagoons

These are the lagoons in which liquid is thoroughly aerated from the bottom so as to keep all solids in suspension.

- No settlement of solids occurs in such lagoons

- Solid concentration in effluent is very high, so further treatment is necessary.

Therefore, Facultative lagoons are most commonly used.

Advantages of lagoons

Simplicity in operation

Less machinery used

Low power consumption (0.75 w/cum lagoon volume)

Other Characteristics

- Depth of lagoons: 2-5m

- Period of detention: 2-5 days

- BOD removal efficiency: 90%

- Nitrification absent

- Sludge accumulation @ 0.04 cum/person/year

- Sludge removal once in 5 years: 95% and sludge extremely low.