Site pages

Current course

Participants

General

Module 1. History and types of greenhouse

Module 2.Function and features of greenhouse

Module 3.Scope and development of greenhouse techn...

Module 4.Location, planning and various components...

Module 5.Design criteria and calculations

Module 6. Construction materials and methods of co...

Module 7. Covering material and characteristics

Module 8. Solar heat transfer

Module 9. Solar fraction for greenhouse

Module 10. Steady state analysis of greenhouse

Module No. 11 Greenhouse Heating, Cooling, Sheddin...

Module 12. Carbon dioxide generation and monitorin...

Module 13. Instrumentation and & computerized ...

Module 14. Watering, fertilization, root substrate...

Module 15. Containers and benches

Module 16. Plant nutrition, Alternative cropping s...

Module 17. Plant tissue culture

Module 18. Chemical growth regulation

Module 19. Disease control, integrated pest manage...

Module 20: Post Production Quality and Handling

Module 21: Cost analysis of greenhouse Production

Module 22. Application of greenhouse & its rep...

Lesson 18 Cooling, Shedding and Ventilation Systems of Greenhouse

18.1 INTRODUCTION

Environmental control for heating and cooling uniformity is a very important design consideration to maintain desired environmental set point conditions inside a greenhouse. However, the distribution of heat or cooling is difficult, and a uniformly controlled environment may not result. Non uniform environments cause differential plant growth rates, potential disease problems, unpredictable results with nutrition or hormonal application, and generally a more difficult plant production system to manage.

For the most effective and uniform cooling and heating, the rows of plants should be arranged in the direction parallel with the ridge or gutters of the greenhouse structure. For ventilation, this assumes that the ventilation system (fans and air inlets) would be located on the end walls (perpendicular to the direction of the gutters). If airflow is restricted and non-uniform, then the ventilation system cannot effectively cool the plant, nor provide the sufficient air exchange for humidity reduction (disease control) and replenishing carbon dioxide. Evaporative cooling systems, whether fan and pad, or high-pressure fog, are highly dependent upon effective and uniform ventilation, as well.

18.2 VENTILATION

Greenhouses can be mechanically or naturally ventilated. Mechanical ventilation requires (louvered) inlet openings, exhaust fans, and electricity to operate the fans. When designed properly, mechanical ventilation is able to provide adequate cooling under a wide variety of weather conditions.

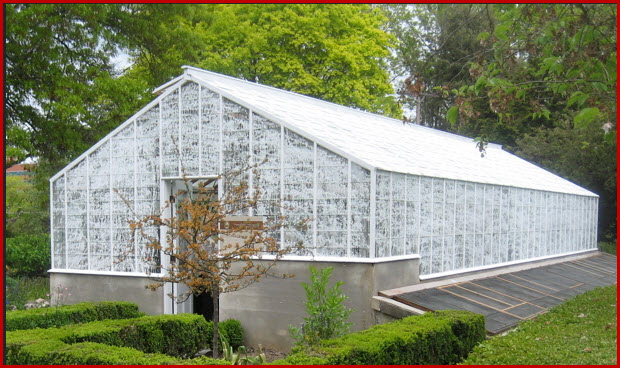

Natural ventilation (Figure 18.2.1) works based on two physical phenomena: thermal buoyancy (warm air is less dense and rises) and the so-called “wind effect” (wind blowing outside the greenhouse creates small pressure differences between the windward and leeward side of the greenhouse causing air to move towards the leeward side). All that is needed are (strategically located) inlet and outlet openings, vent window motors, and electricity to operate the motors. In some cases, the vent window positions are changed manually, eliminating the need for

motors and electricity, but increasing the amount of labour since frequent adjustments are necessary. Compared to mechanical ventilation systems, electrically operated natural ventilation systems use a lot less electricity and produce (some) noise only when the vent window position is changed. When using a natural ventilation system, additional cooling can be provided by a fog system.

Unfortunately, natural ventilation does not work very well on warm days when the

outside wind velocity is low (less than 200 feet per minute).

Keep in mind that whether using either system with no other cooling capabilities, the indoor temperature cannot be lowered below the outdoor temperature. Due to the long and narrow design of most free standing greenhouses, mechanical ventilation systems usually move the air along the length of the greenhouse (the exhaust fans and inlet openings are installed in opposite end walls), while natural ventilation systems provide crosswise ventilation (using side wall and roof vents; fig 18.2.2). In gutter-connected greenhouses, mechanical ventilation systems inlets and outlets can be installed in the side- or end walls, while natural ventilation systems usually consist of only roof vents. Extreme natural ventilation systems include the open-roof greenhouse design (fig 18.2.3), where the very large maximum ventilation opening does not allow the indoor temperature to exceed the outdoor temperature. This is often not attainable with mechanically ventilated greenhouses due to the very large amounts of air that such systems would have to move through the greenhouse to accomplish the same results. When insect screens are installed in ventilation openings, the additional resistance to airflow created by the screen material has to be taken into account to ensure proper ventilation rates. Often, the screen area is larger compared to the inlet area to allow sufficient amounts of air to enter the greenhouse. Whichever ventilation system is used, uniform air distribution inside the greenhouse is important because uniform crop production is only possible when every plant experiences the same environmental conditions. Therefore, horizontal airflow fans are frequently installed to ensure proper air mixing.

Fig 18.2.1 Natural Ventilation

(Source: Both A.J ,(2008) )

Fig 18.2.2 Natural ventilation providing crosswise ventilation

(Source: http://www.nexuscorp.com )

Fig 18.2.3 Open roof ventilation design

(Source: http://aesop.rutgers.edu )

18.3 COOLING

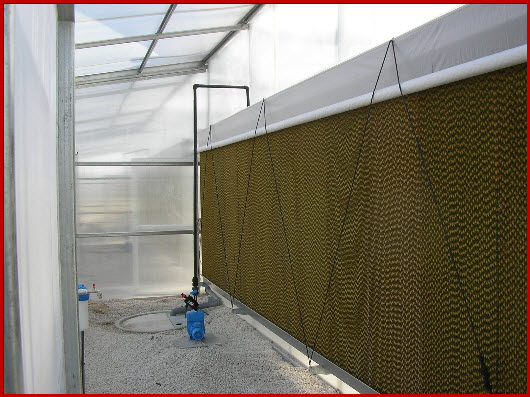

When the regular ventilation system is unable to provide sufficient cooling for greenhouse temperature control, additional cooling is needed. Two cooling systems, the fan and pad and the fog system, are commonly used in greenhouses and both make use of the cooling effect resulting from the evaporation of water (Figures 18.3.1 and 18.3.2). The process of evaporation requires heat that is removed from the air surrounding the evaporating water.

Fig 18.3.1 Evaporative cooling pad

Fig 18.3.2 Greenhouse misting system

18.3.1 Fan and pad evaporative cooling system

Fan and pad systems consist of exhaust fans at one end of the greenhouse and a pump circulating water through and over a porous pad (Figure 18.3.3) installed at the opposite end of the greenhouse

Fig 18.3.3 Pump circulating water through and over a porous pad

(Source: http://www.gildan.co.il )

If all vents and doors are closed when the fans operate, air is pulled through the wetted pads and water evaporates. As each gallon of water is evaporated, 8,100 BTUs of heat energy is absorbed from the air by the water during the change from liquid to vapour. Removing energy from the air lowers the temperature of the air being introduced into the greenhouse.

The air temperature reduces after passing through the pads. As the air moves across the house to the fans, it picks up heat from solar radiation, plants, and soil, and the temperature of air increases gradually. The resulting temperature increases as air moves down the greenhouse & produces a temperature gradient across the length of the greenhouse, with the pad side being coolest and the fan side warmest.

If the efficiency of the evaporative cooling system is known, the temperature of air exiting a cooling pad can be calculated by the following equation.

Tcool=Tout – (% efficiency) (Tout-Twb)

Where,

Tcool = temperature of air exiting cooling pad;

Tout = temperature of the outside air;

Twb= wet bulb temperature of the outside air.

A well designed, properly installed and operated evaporative cooling system may have an efficiency of up to 85 percent.

18.3.1.1 Factors influencing fan and pad evaporative cooling systems:

Operational Considerations: It is very important to keep the building as tight as possible so entering air will be forced through the pads. Make sure that all doors and other openings are kept closed except when in use and that any gap in the greenhouse coverings is sealed.

Greenhouse location and orientation: Orientation of the greenhouse relative to other buildings or structures and in relation to prevailing summer winds influence the efficiency of operation. Fan arrangements and locations of the fans and pads should be determined by greenhouse location and orientation.

Types of cooling pad: Compare costs, life expectancy claims, cooling efficiencies, and probability of maintenance problems before selecting the one that is best for your operation.

Cooling pad area: The amount of pad area needed depends upon several factors including the type of pad material used. The pads should be continuous along the entire length of the wall.

Water flow rate: To maximize operating efficiency, you must have adequate pad surface area and an adequate water supply and distribution system. The amount of water needed will vary with the type of system used, but, normally, complete pad surface wetting occurs when about 1/3 gallon of water per foot of pad length is recirculated.

Problems with cooling pads: Evaporative cooling pads have severe problems. They lose efficiency due to clogging from impurities in the water, algae growth and decay. If the pad material is clogged or decomposed its ability to function as designed is impaired.

Airflow through cooling pads: The required face velocity of the air will depend upon the pad material. Follow manufacturer's suggestions. This velocity will determine the number of square feet of pad area needed for a house of a given configuration.

Fans: Regardless of the type of pad material used, the fans should have the capacity to provide a minimum of one air change per minute in the greenhouse. Equip the fans with automatic shutters to eliminate back drafts when a fan is not operating (Figure 18.3.4).

Fig 18.3.4 Ventilation and cooling fans equipped with anti-back draft shutters.

(Source: http://www.digood.com )

18.3.1.2 Location of fan and cooling systems

The best distance between the pad and exhaust fans is a tradeoff between the optimum dimensions of the greenhouse (based on efficiency, function, and operation) and the tolerance of the crop to higher temperatures. The greater the range of the crop's temperature tolerance, the greater the distance between pad and fans can be. It is not practical to separate the pad and exhaust fans by more than 200 feet. A distance of 150 feet or less is preferred.

18.3.2 Fog Cooling System

The fog evaporative cooling system (Fig 18.3.5), introduced in green houses in 1980, operates on the same cooling principle as the fan and pad cooling system but uses quite different arrangement. A high pressure pumping apparatus generates fog containing water droplets with a mean size of less than 10 microns using suitable nozzles. These droplets are sufficiently small to stay suspended in air while they are evaporating. Fog is dispersed throughout the green house, cooling the air everywhere. As this system does not wet the foliage, there is less scope for disease and pest attack. The plants stay dry throughout the process. This system is equally useful for seed germination and propagation since it eliminates the need for a mist system. Both types of summer evaporative cooling system can reduce the greenhouse air temperature. The fan-and pad system can lower the temperature of incoming air by about 80% of the difference between the dry and wet bulb temperatures while the fog cooling system can lower the temperature by nearly 100 % difference. This is due to the fact that complete evaporation of the water does not take place in fad and pad system due to bigger droplet size, whereas in the fog cooling system, complete evaporation takes place because of the minute size of the water droplets. Thus lesser the dryness of the air, greater evaporative cooling is possible.

Fig 18.3.5 Fog evaporative cooling system

(Source: http://mistafog.com.au )

18.4 SHADING

Greenhouse shading is a procedure for cooling which attempts to reduce the amount of solar radiation which reaches the plants. By reducing the solar load on the greenhouse, the air temperature difference is smaller, making the absolute air temperatures inside the greenhouse closer to the outside temperatures.

Secondly, the leaf surface temperature can be significantly reduced. This may be the more important factor, since it affects the plant processes such as photorespiration, an unwanted process that consumes the stored energy reserves within the leaf.

When leaf temperature is not a limiting factor to net photosynthesis, shading may reduce the growth and development rate of the plants by limiting photosynthesis as a result of lowered light intensity. This could prolong the plant growth time needed to reach maturity or inhibit plant quality for certain crops.

Typically during the time of the year when shading is needed for the purpose of cooling, solar radiation is not a limiting growth factor. However a good control system could prevent most shade related problems. It can easily deploy an automated shade curtain only at desired times of the day. This control could be based on the measured solar radiation intensity or more simply on the time of the day.

The traditional way for shading is to apply a semi-permanent shading compound to the outer glazing of the greenhouse. In glasshouses and more recently polyethylene greenhouses, a white liquid is used which could easily be applied by spraying. (Fig 18.4.1)

Fig 18.4.1 Greenhouse shading with white paint

(Source: http://www.interiordesigninspiration.net )

Another procedure for shading consists of attaching a black polypropylene mesh screening on the outer glazing (Fig 18.4.2). The density of the mesh determines the amount of shading desired. Shading can be obtained from 30 to 92%. The material can be made in widths from 1.8 to 7.3 m (6 to 24 feet).

Fig 18.4.2 Greenhouse shading with black polypropylene mesh screening

(Source: http://www.harpstarps.com )

- Application and removal of either of these shading procedures is typically completed once for each season. They do not allow for a choice of shading on a day-to-day basis, should it be necessary.

- More recently, internal shading systems have been installed (Fig 18.4.3). They may be the same system which is utilized as the energy saving curtain in the night.

Fig 18.4.3 Internal shading system of greenhouse

(Source: http://www.gothicarchgreenhouses.com )

These are typically attached to mechanisms for deploying and retracting the curtain after sunset and prior to sunrise. However they can be utilized during the day for shading assuming that light transmission is not severely reduced. In some instances, a separate system for shading, in addition to the energy curtain is installed. Each would be used independently.

Retractable roof greenhouse designs (Fig 18.4.4) can be utilized as shade structures. Retractable roof greenhouses can be covered with translucent, water-impermeable plastic materials, and be completely opened to the outside environment, or closed to provide a traditional plastic greenhouse structure and environment. They may also be covered with a woven, water-porous, shade curtain material, and be completely opened to the outside, or closed to provide a traditional shade greenhouse environment.

Fig 18.4.4 retractable roof greenhouse

(Source: http://www.freshplaza.com )

The exciting feature in both of these designs is for protected plant growth, with the option for an open cover plant growth similar to outdoor production. The challenge to these structures is that they are open to insect pests.

REFERENCES

Both A.J, (2008) “Greenhouse Temperature Management”, New Jersey Agricultural Experiment Station

Gene A. Giacomelli (2003) “Cooling System : Natural Ventilation and shading” MS GH short course

Bucklin, R.A. (2013). “Fan and pad greenhouse evaporative cooling systems” Circular 1135, one of a series of the Department of Agricultural and Biological Engineering, Florida Cooperative Extension Service, Institute of Food and Agricultural Sciences, University of Florida.