Site pages

Current course

Participants

General

Module 1. Dairy Development in India

Module 2. Engineering, thermal and chemical proper...

Module 3. Unit operation of various dairy and food...

Module 4. Working principles of equipment for rece...

Module 5. Dairy plant design and layout, compositi...

Module 6. Deterioration in products and their cont...

Module 7. Physical, chemical and biological method...

Module 8. Changes undergone by the food components...

Module 9. Plant utilities requirement.

References

Lesson 6. Unit operation of various dairy and food processing systems-I

6. INTRODUCTION

The study of process engineering is an attempt to combine all forms of physical processing into a small number of basic operations, which are called unit operations. Food processes may seem bewildering in their diversity, but careful analysis will show that these complicated and differing processes can be broken down into a small number of unit operations. For example, heating, there are innumerable instances occur in every food industry. There are many reasons for heating and cooling - for example, pasteurization of milk, baking of bread, freezing of meat and frying of potato slices in oils. But in process engineering, the prime considerations shall be the extent of the heating or cooling that is required the conditions under which this must be accomplished. Thus, this physical process qualifies to be called a unit operation.

Various unit operations common to many food products include heating/cooling (heat exchange), materials handling, cleaning, concentrating, controlling, disintegrating, drying, evaporating, fermentation, forming, mixing, packaging, pumping and separating.

6.1 Material handling

Materials handling includes variety of operations such as mechanical harvesting on the farm, transportation of live cattle, refrigerated transportation of perishable produce and pneumatic conveying of flour from rail cargo to bakery storage bins.

Throughout such operations it is very important to minimize product losses, to maintain raw material quality (e.g., vitamin content and physical appearance), to maintain sanitary conditions, to minimize bacterial growth and to maintain timing of all transfers and deliveries so that holdup time can be minimized, which can be uneconomical as well as harmful to the quality of the product.

The movement of produce from farm to processing area may lead to change it into many different forms. For example, Grapes are transferred by tractor/ truck/ trailer to juice plants/ wineries, where they are graded, washed and further processed. There is a limit to the size the trucks/trailers may be and the length of time the fruit may be held since fruits and vegetables are alive, respire and can lead to rise in the temperature of a batch to the point where spoilage may occur.

Handling of sugar and flour is also a challenging work. When dry sugar reaches processing plants, via truck trailers or rail, it is moved to storage tanks via a pneumatic conveying system. The sugar has a tendency to cake if the storage time, temperature and humidity are not maintained. Improper movement of sugar may also lead to dusting and buildup of static electricity, which may cause an explosion, as the sugar particles are highly combustible. The same is the case with the flour industry. Proper method of material handling has the additional advantages of preventing loss of desirable volatile compounds from the spices, irritation to personnel and flavor exchange between different spices.

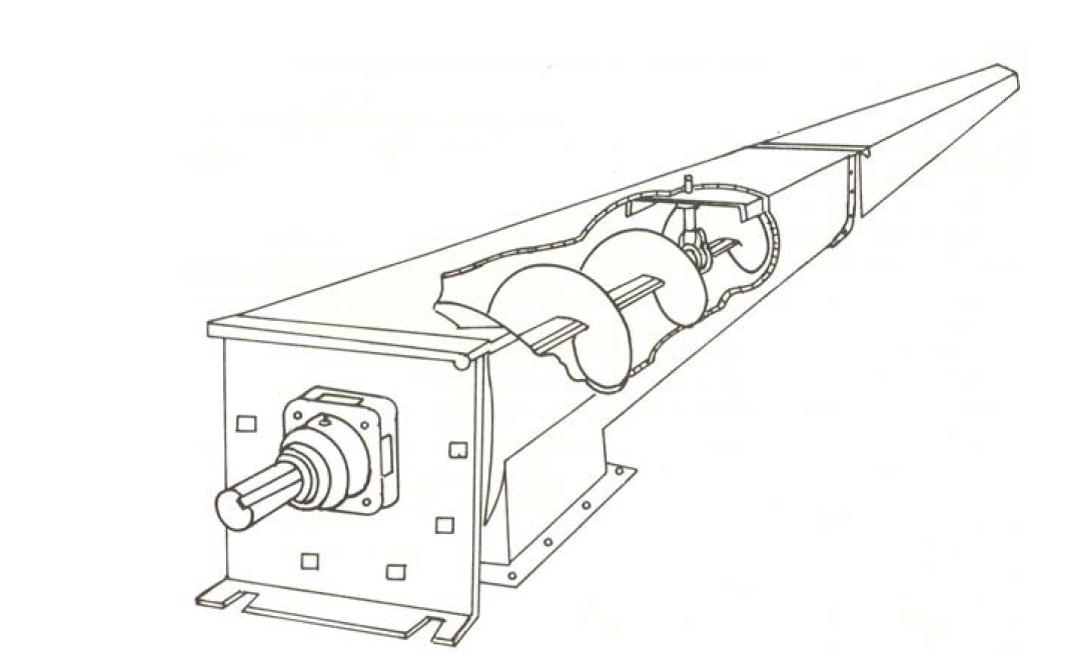

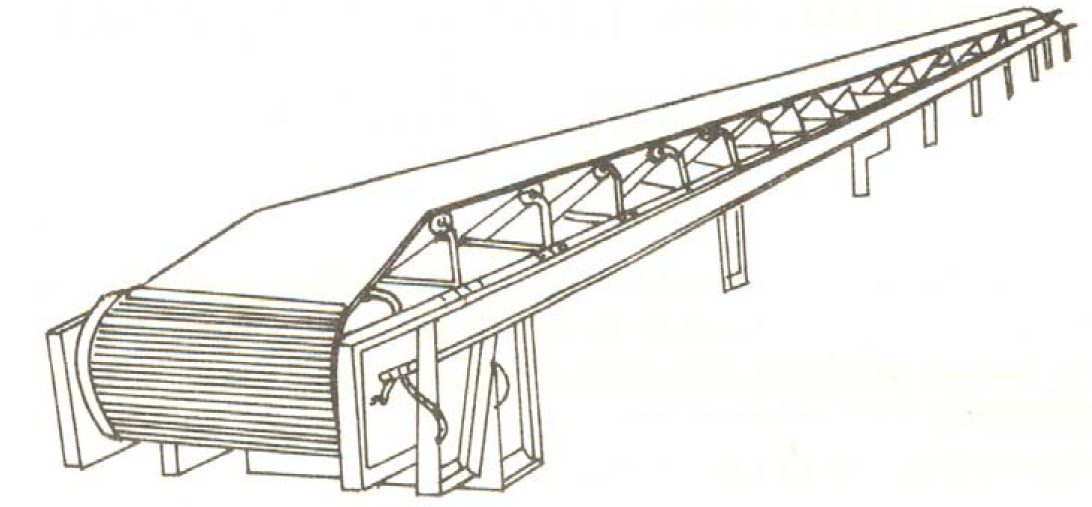

The wide variety of screw conveyors, bucket conveyors, belt conveyors and vibratory conveyors in food plants are required for conveying and handling of variety of food materials.

|

|

| Screw Conveyor | Belt Conveyor |

The material handling is intended to achieve following major objectives:

(1) Acceptable product quality

(2) Proper sanitation

(3) Minimum holding time

(4) Minimum loss of product and

(5) Minimum bacterial growth

6.2 Pumping

One of the most common unit operations in the food industry is the moving of liquids from one location or processing step to another by pumping. There are many kinds of pumps available depending upon the nature of the food to be pumped. One common type is a rotary gear pump, where the inner gears rotates and sucks food into the pump housing and subsequently squeezes food out of the pump housing. For motives of mechanical efficiency, with such pump, close clearances between the gears and housing are necessary. Although such pump is effective for moving liquids and pastes, it may crush the chunk-type foods, reducing them to purees. A single screw pump is best suitable for pumping food with large suspended pieces without disintegration. Such pumps are also known as progressing cavity pumps and can be selected for large clearances of the cavities between the rotating center rotor and the housing. The food is gently pushed from large clearance to large clearance by the screw like action of the turning rotor. Food pieces such as corn kernels, grapes and even small shrimp can easily be pumped without any physical damage that would have been ground up in the gear-type pump. Centrifugal pumps are generally used for moving the liquids to the plate heat exchangers to avoid excessive pressure buildup within plates.

An essential feature for all food pumps is ease of disassembly for thorough cleaning. Today's sanitary stainless steel pumps in many cases can be disassembled in minutes with a single tool.

6.3 Cleaning

All the foods are naturally available/ grown in open environment. This leads to compulsion in cleaning all foods before consumption. It may vary from simple removal of dirt from fruits and vegetables with an abrasive brush to the complex removal of bacteria from milk by microfiltration. Grains are also cleaned of stones by passing through screening with or without vibrations before they are used.

Cleaning can be done using water, steam, pressurized air, brushes, vacuum, magnetic attraction of metal contaminants, mechanical separation and other techniques, depending on the characteristic of the product and dust/dirt. The purity of water used in the soft drink bottling industry must exceed many of the standards found adequate for drinking water. If a high degree of carbonation is to be achieved, then the water used in making the drink must be remarkably free of dust particles, colloidal particles and certain inorganic salts, as these minimize carbon dioxide solubility and promote excessive escape of gas bubbles. To adequately purify this water treatment with controlled chemical flocculation of suspended matter, sand filtration, carbon purification, microfiltration and de-aeration may be employed. This is no longer the unit operation of cleaning but a total cleaning process.

Some cleaning methods are defined by surface characteristics of the product. For example, pineapples have an asymmetric surface, high-pressure water jets are used for removing the dirt from the grooves below the eyes of the fruit. Similarly, different food materials require special cleaning equipment and methods. For the cleaning of equipment, walls and floors of the plant, the chemical and physical properties of both the surface to be cleaned and the type of soil must be taken into consideration. Many types of soil can be removed with mild alkaline detergents, but strong alkali may be required for more tenacious deposits and heavy deposits of fats and oils or built up protein deposits. Some hard soils of salts, formed during heating, will require strong acids to efficiently clean the heating surface.

6.4 Mixing

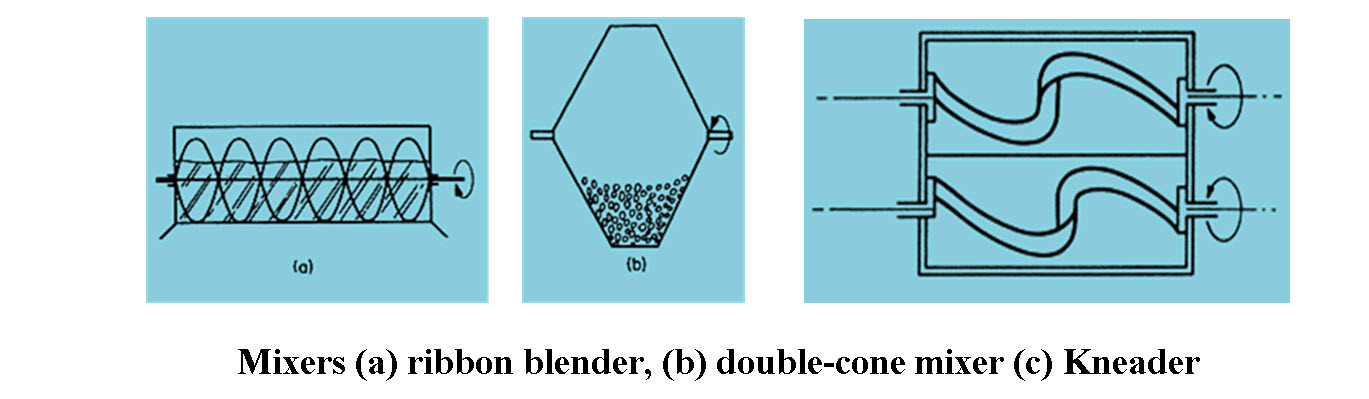

One may wish to mix solids with solids, liquids with liquids, liquids with solids, gases with liquids and so on. Like pumps, there are many kinds of mixers available depending on the materials to be mixed.

For simple mixing of dry ingredients such as the components that make up a baking powder, a conical blender is suitable. The tumbling action in the bowl continued for 10-20 min makes the mixture is homogenous. If we want to prepare a dry cake mix, we must cut the shortening into the flour, sugar and other dry ingredients in order to produce a fluffy homogeneous dry mix. We may use a ribbon blender, which is a horizontal trough with one of several types of mixing elements rotating within it. The efficiency of mixing depends on the choice of the mixing element. These types of ribbon like elements suitable for cutting in shortening. For mixing solids into liquids, a propeller mounted within a stainless steel vat is most desirable. There are many types of propellers, turbines and paddles available for such kind of mixing.

All types of mixers do almost similar work on the material being mixed and cause some elevation in temperature. It is generally desirable to control the temperature rise. However, to work on heavy viscous materials special mixers are also chosen. Such mixers may have arms that knead dough, or paddles and arms that work butter. These working mixers are designed with precise geometries to maximize efficiency and minimize energy requirements to achieve the optimum mixing/working operation. Some mixers are designed to beat air into a product while it is being mixed. The scraper-beater found in ice cream freezers is an example (Fig. ANIMATION TO BE DEVELOPED). During freezing of ice-cream mix in the freezer cylinder, the beating element, or dasher, turns within the bowl. It not only keeps on scraping the mix from the cylinder surface to speed up freezing and make product more uniform, but it also incorporates air into the mix being frozen to give the ice-cream with desired volume rise or overrun and smooth texture.

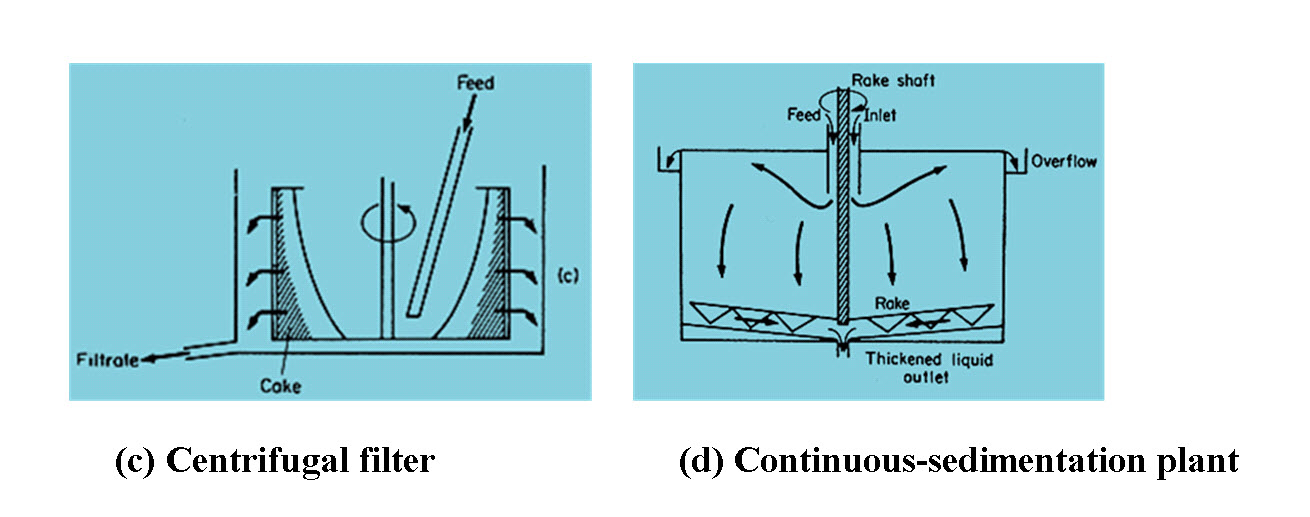

6.5 Separating

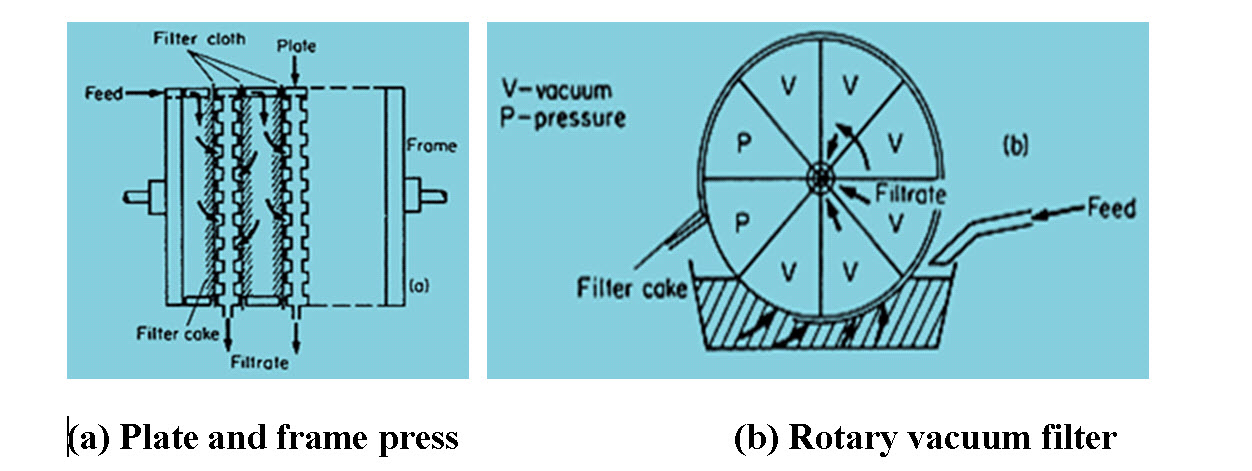

Separation can involve separating a solid from a solid, as in the peeling of potatoes or the shelling of nuts; separating a solid from a liquid, as in the many types of filtration; or a liquid from a solid, as in pressing juice from a fruit. It might involve the separation of a liquid from a liquid, as in centrifuging oil from water, or removing a gas from a solid or a liquid, as in vacuum removal of air from canned food in vacuum canning.

One of the most common forms of separating in the food industry is the hand sorting and grading of individual units as in case of vegetables and fruits. However, mechanical and electronic sorting devices have been developed because of the high cost of labor. Difference in color can be detected with a photocell and off-colored products are rejected. This can be done at massive speeds with automatic rejection of discolored or moldy nuts or kernels of grain that flow past the photocell. In case of manufacturing of peanut butter from peanuts, each peanut individually passes through a light beam that activates a jet of air due to change in reflection and blows off the discolored peanuts from the main stream. Light shining through eggs can detect blood spots and automatically reject such eggs. By passing fruits or vegetables over different size screens, holes or slits, automatic separation according to size is easily accomplished.

The skins of fruits and vegetables can be separated using a lye peeler. Fruits such as peaches, apricots etc. are passed through a heated lye solution where the skin of fruits is softened. Soft skin can be easily slipped from the fruit by gentle action of mechanical fingers or by jets of water. Density difference of the fruit and skin can then be used to float away the removed skin.

To extract corn oil from corn kernels, the germ portion of the corn first is separated from the rest of the kernel by milling; then the oil is separated from the germ by applying high pressure to the germ in an oil press. Similarly, pressure is used to squeeze oil out of peanuts, soybeans and cottonseeds. The traces of oil can be separated from the pressed cake by the use of fat solvents. The separation of the oil from the solvent can be achieved by distillation apparatus.

Salt from sea water or sugar from sugar cane juice can be separated by crystallization. Here, evaporation of some of the water makes the solution super saturated and forms crystals. Since crystals are quite pure, this may also be considered as purification process. The crystals are then separated from the suspending liquid by centrifugation. Newer methods of separation include several techniques involving manufactured membranes with porosities or permeabilities capable of fractionating the colloidal and macromolecular size level. Ultra filtration uses membranes of such porosity that water and low-molecular-weight salts, acids and bases pass through the membrane but larger protein and sugar molecules are retained. This selective permeation process may also be carried out at ambient temperatures to avoid the damage to heat sensitive food constituents that is common with water evaporation at high temperatures. Further, removal of acids and salts with the water prevents their concentration, which would otherwise be detrimental to sensitive retained solids.

6.6 Size Reduction

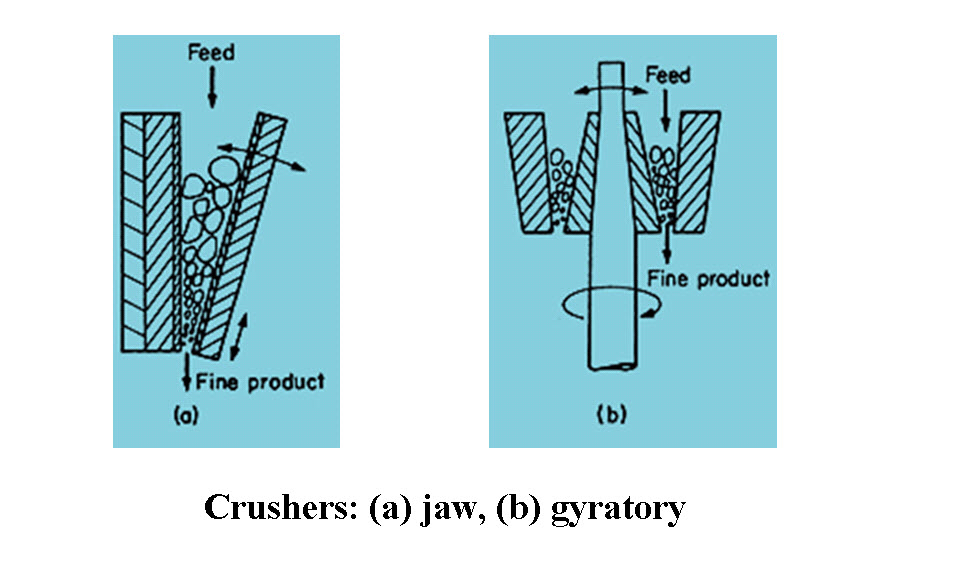

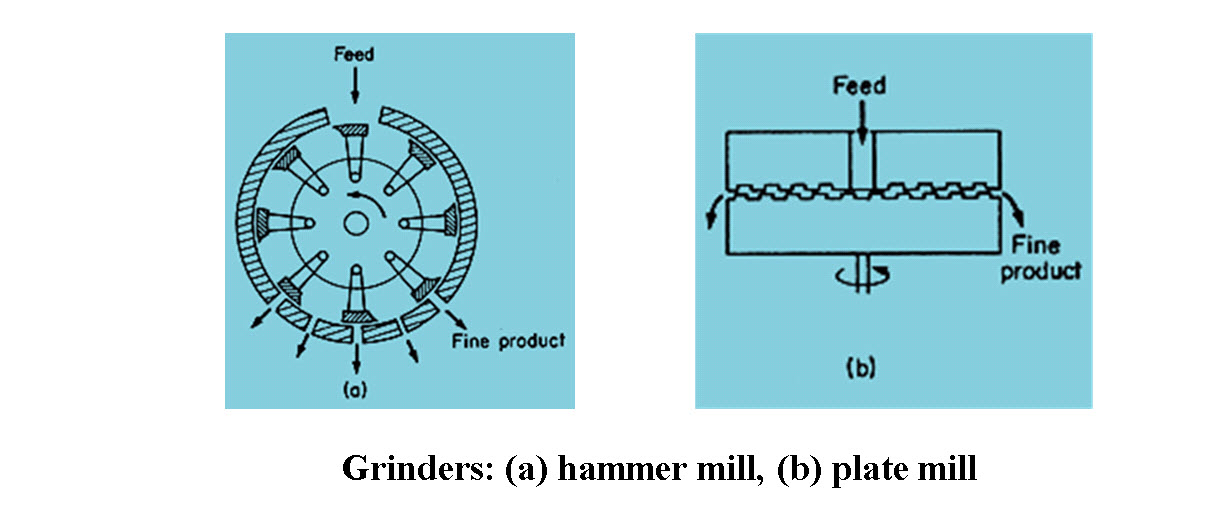

The term size reduction means particles of solids are cut or broken into smaller pieces. Throughout the process industries solids are reduced in size and shape by different methods for different purposes. Size reduction is carried out by mechanical means without any change in chemical properties of the materials. Here, the chunks of large particles are crushed or reduced to workable size. In this process uniformity in size and shape of the individual particles of the resultant product is desirable, but difficult to attain. Reduced size leads to increased reactivity of solids, helps separation of unwanted ingredients and reduces the bulk of fibrous materials for easier handling.

The equipment mostly used for size reduction of agricultural products are crushers and grinders. Usually the performance of any milling equipment is compared with respect to an ideal operation as standard. Amount of power required to create smaller particles and desired uniformity of size are the parameters for the efficient of operation. The ground product consists of a mixture of various particle sizes irrespective of uniformity of feed size. In some equipment there is a provision to control the magnitude of the largest particles like the hammer mill, but the fine size is beyond control. In some size reducing machine fines are minimized but they can’t be eliminated.

There are many methods of size reduction, but only four of them are commonly used: (1) compression, (2) impact, (3) attrition or rubbing and (4) cutting. A nutcracker, a hammer, a file and a pair of scissors exemplify these four types of action. In general, compression is used for coarse reduction of hard solids, to give relatively few fines; impact gives coarse, medium, or fine products; attrition yields very fine products from soft, nonabrasive materials. Cutting gives a definite particle size and sometimes a definite shape, with few or no fines.

6.6.1 Crushing

When an external force is applied on a material in excess of its strength, the material fails because of its rupture in many directions. The particles produced after crushing are irregular in shape and size. Food grain flour, grits and meal, ground feed for livestock are made by crushing process. Crushing is also used to extract oil from oilseeds and juice from sugarcane.

6.6.2 Impact

When a material is subjected to sudden blow of force in excess of its strength, it fails, like cracking of nut with the help of a hammer. Operation of hammer mill is an example of dynamic force application by impact method.

6.6.3 Cutting

In this method, size reduction is accomplished by forcing a knife through the material, where minimum deformation and rupture of the material is achieved. An ideal knife is of excellent sharpness and as thin as practicable. The size of vegetables and fruits are reduced by cutting by knives.

6.6.4 Shearing

It combines cutting and crushing and consist of units like a knife and a bar. In an ideal shearing unit the clearance between the bar and the knife should be as small as practicable and the knife as sharp and thin as possible.