Site pages

Current course

Participants

General

MODULE 1. PRINCIPLES AND TYPES OF CUTTING MECHANISM

MODULE 2. CONSTRUCTION AND ADJUSTMENT OF SHEAR AND...

MODULE 3. CROP HARVESTING MACHINERY

MODULE 4. FORAGE HARVESTING, CHOPPING AND HANLING ...

MODULE 5. THRESHING MECHANICS, TYPES OF THRESHES, ...

MODULE 6. MAIZE HARVESTING AND SHELLING EQUIPMENT

MODULE 7. ROOT CROP HARVESTING EQUIPMENT

MODULE 8. COTTON PICKING AND SUGARCANE HARVESTING ...

MODULE 9. PRINCIPLES OF FRUIT HARVESTING TOOLS AND...

MODULE 10. HORTICULTURAL TOOLS AND GADGETS

MODULE 11. TESTING OF FARM MACHINES, RELATED TEST ...

MODULE 12. SELECTION AND MANAGEMENT OF FARM MACHIN...

LESSON 13. MAIZE HARVESTING EQUIPMENT, COMPONENTS, ADJUSTMENTS

Corn occupies the greatest area as a field crop and also acts as the important source of food. During 1920s mechanical corn pickers were developed with the adaptation of the tractor PTO to their operation. The first picker-Sheller was developed in middle 1930s. Then attempts were made to adapt the grain combine for harvesting the corn, which includes the feeding the entire corn plant into the machine. The early investigators concluded that corn can be shelled and cleaned with a combine but introduction of the stalks into the machine was the major problem. In 1950s rasp-bar cylinder was evaluated as the corn husker or the sheller, same problem of introduction of the stalks into the machine existed. The next step in the evolutionary process was to equip the combines with corn snapping units in order to leave the stalks in the field and introduce only the ears into the machine (Fig. 1). Following the development of acceptable corn heads, the popularity of grain combines for harvesting corn increased rapidly during 1960s. In 1970s approximately 70% of the corn produced in 5 of the principal corn-belt states in USA was harvested by combines equipped with corn heads.

The maize crop is harvested when the husk has turned yellow and the grains are hard enough having not more than 20 percent moisture. Ears are removed from the standing crop. Harvested ears are dried in the sun before shelling.

The corn picker is a single or two-row machine equipped with snapping rolls to remove the ears from standing stalks. It replaces the slow and hard hand method of harvesting. The chains guide the stalks into throat between the downwardly revolving snapping rolls, which pinch and snap the ears from stalk. The ears then moved to elevator, which conveys them to trailer drawn either beside or behind the machine. The ears can also be snapped, husked and shelled in a continuous operation. Maize harvesters (corn picker) may be classified as:

a) Snappers

b) Picker-huskers

c) Picker-shellers

d) Grain combines equipped with corn heads

Three different types of machines are available for harvesting corn. The simplest machine snaps the ears from stalks and does not remove husk called snapper. Picker-husker is one that snaps the ears from stalks and removes the husk also. The most recent development is a machine that snaps the ears from stalks and shells in the field. This type of machine is called picker-sheller. Tractor-mounted and self-propelled corn harvesters are available in different sizes i.e. 2-row, 4-row and 6-row.

Snappers consist of all basic components plus an elevating conveyor to deliver the ears (mostly not husked) into a trailing wagon. The addition of a husking bed to remove the husks from the ears identifies the machine as a corn picker. A picker-sheller has a shelling unit instead of a husking unit. Sometimes these units are interchangeable. The shelled corn may be delivered to a trailing wagon or to a tank on the machine. When a grain combine is to be used for corn, a corn head is installed in place of the grain header. A corn head has the basic gathering and snapping components listed above (similar to a corn snapper) plus a conveying system to deliver the ears to the combine cylinder for shelling.

Both mounted and pull type pickers and snappers are available. Mounted units are mostly 2-row machines, whereas 1-row, 2-row, and 3-row sizes are common with pull type machines. Picker shellers are usually two row machines. Most 2-row machines have snapping-unit center distances of about 102 cm, but a narrow row models for 76 cm row spacing are available. Differences of 56 to 80 cm between the row spacing and the snapping-unit center-line distances are tolerable in 2-row harvesters.

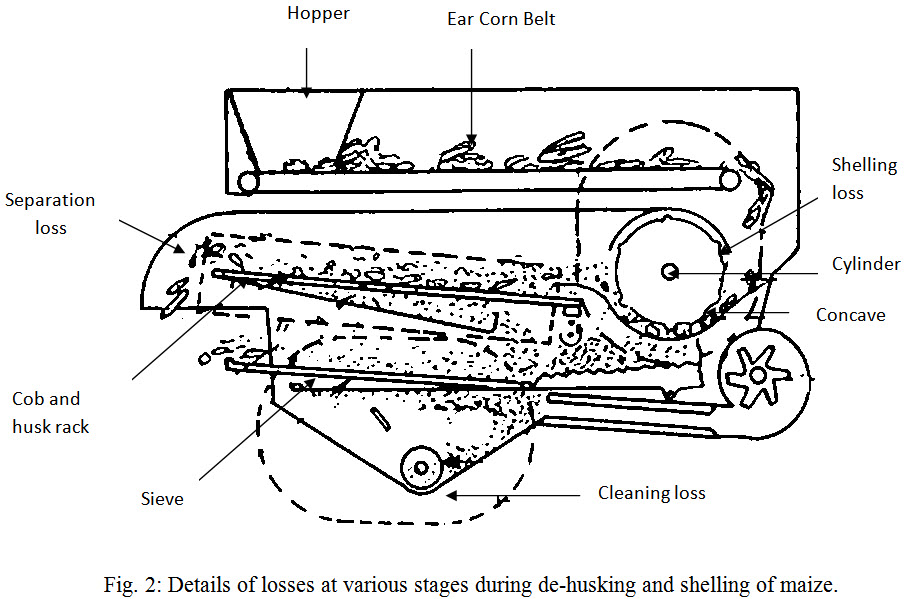

There are many factors that affect the performance of corn pickers. They are plant characteristics such as variety, condition of stalks, height of ears, toughness of ear shanks, size of ears and thick and tight husk; mechanical factors such as type of snapping roll surface, clearance between snapping rolls, rate of travel and timing of snapping rollers. Timeliness of harvesting, weather conditions, cleanliness of field, row length and row spacing also affect the performance of machine. Field losses in snapping ears from standing corn stalks are largely attributed to lodging of stalks, date of harvest and rate of travel of machine. Losses increase when picking is delayed and rate of travel is increased but decrease as the moisture content of cob decrease. Fig. 2 gives the details of losses at various stages during the de-husking and shelling of maize crop.

Shelling and cleaning in a picker-sheller

Although at least one model of picker-sheller has had a rasp-bar cylinder and concave as the shelling unit, most picker-shellers have axial-flow cage type shellers. A cage-type sheller has a rotating cylinder with lugs, spiral flutes, or paddles around the periphery. The cylinder operates within a stationary cage that is 1020 to 1420 mm long and 280 to 380 mm in diameter. The cage periphery is made of perforated metal or parallel round bars and has openings large enough to permit easy passage of shelled kernels but not the cobs. The cylinder is operated at 700 to 800 r/min and has a peripheral speed of 6.1 to 10.2 m/s.

Ears form snapping units are fed radially into an opening at one end of the cage and pass circumferentially and longitudinally along the cylinder during the shelling process. Shelling is accomplished primarily by rubbing and rolling of ears and cobs against each other and against the cage (concave) and the rotating cylinder. The length of time that the ears remain in the shelling unit can be varied, by means of an adjustable cob gate at the discharge end of the cage, to accommodate different crop conditions.

The shelled corn falls through the openings in the cage and is conveyed to the tank or wagon. Light trash is removed from the shelled corn by means of an air blast or with a suction-type fan. On some shelling units the material discharged from cage passes over a cleaning shoe for final separation of shelled corn from the cobs, husks, and other trash.

Functional components of corn harvester: The basic components for all types of maize harvester include a gathering unit to guide the stalks into the machine, snapping rolls to remove the ears from the stalks, and lugged gathering chains to assist in feeding the stalks into the rolls and moving the stalks and snapped ears rearward through the snapping zone.

Different units of maize harvester

a) Gathering units: It is relatively simple matter for gathering device control stalks and feed them into the snapping units when the stalks are standing. Unfortunately, many stalks become lodged (leaning or broken) during the season, due to adverse weather conditions, disease, and high plant populations. The gathering assembly must be able to lift lodged stalks and guide them into the snapping unit with a minimum number of ears lost during the process. This requires having pick up devices close to the ground and handling the stalks gently to avoid excessive accelerations and consequent detachment of ears.

b) Snapping units: Two general types of snapping rolls are employed. These may be described as spiral-ribbed or spiral-lugged rolls and straight-fluted rolls. Types have tapered, spiral-ribbed points to facilitate stalk entry, and both types pull the stalks downward between the two rolls. With spiral-ribbed rolls, the ears are snapped off of the stalk when the ears contact the closely spaced rolls. Straight-fluted rolls pull the stalks down between two stripper plates and the ears are snapped off when they contact the plates.

c) Trash removal: special trash rolls are often provided on corn pickers to remove trash and broken stalks not expelled by spiral-ribbed snapping rolls. Fluted sections may be incorporated on the upper ends of the snapping rolls. Transverse, fluted rolls are sometimes mounted at the discharge end of a snapper-ear conveyor. The principal function of the transverse rolls is to remove relatively long sections of stalk. Small blowers may also be used to assist in removing trash.

d) Husking units- The husking unit on a picker has pairs of rolls that grasp the husks and pull them downward between the rolls. Usually, all the husks are taken at once when one is caught. Most husking beds have either 2 or 3 pairs of rolls per corn row. The rolls may be in a separate husking bed at the discharge end of a conveyor from the snapping rolls and fed by snapping roll conveyor. With separate husking beds, there may be one per row or one per machine. Husking rolls are generally 64 to 76 mm in diameter and 760 to 1270 mm long. They operate at about 500 r/min.