Site pages

Current course

Participants

General

MODULE 1. PRINCIPLES AND TYPES OF CUTTING MECHANISM

MODULE 2. CONSTRUCTION AND ADJUSTMENT OF SHEAR AND...

MODULE 3. CROP HARVESTING MACHINERY

MODULE 4. FORAGE HARVESTING, CHOPPING AND HANLING ...

MODULE 5. THRESHING MECHANICS, TYPES OF THRESHES, ...

MODULE 6. MAIZE HARVESTING AND SHELLING EQUIPMENT

MODULE 7. ROOT CROP HARVESTING EQUIPMENT

MODULE 8. COTTON PICKING AND SUGARCANE HARVESTING ...

MODULE 9. PRINCIPLES OF FRUIT HARVESTING TOOLS AND...

MODULE 10. HORTICULTURAL TOOLS AND GADGETS

MODULE 11. TESTING OF FARM MACHINES, RELATED TEST ...

MODULE 12. SELECTION AND MANAGEMENT OF FARM MACHIN...

LESSON 16. POTATO AND GROUNDNUT DIGGERS

Potato-Digger

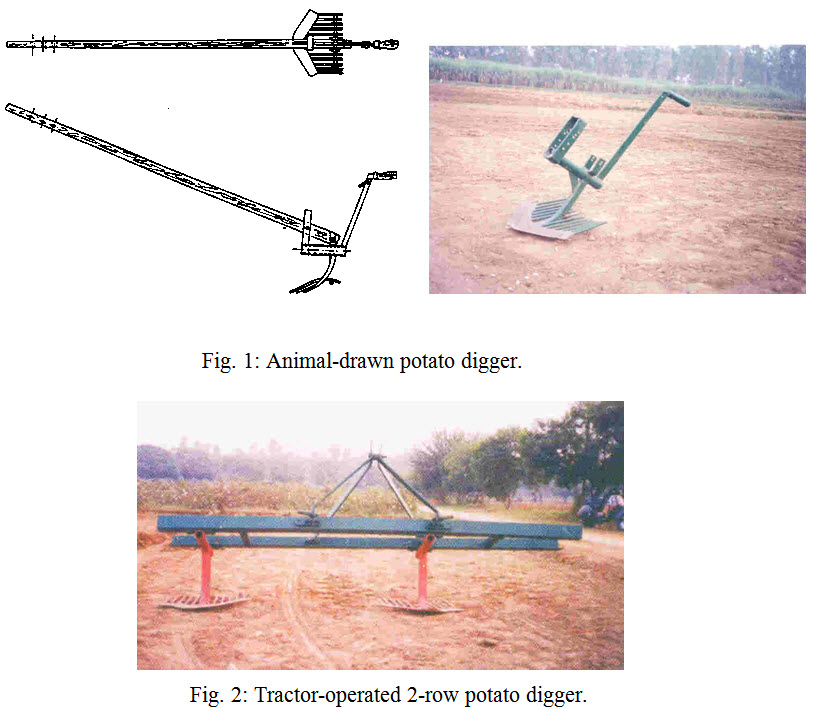

Potato cultivation, especially on large size farms, has got mechanized because; it was not possible to handle the labour intensive operations like sowing and harvesting. Manually harvesting of potatoes requires about 800 man-h/ha, which is quite a labour intensive job. However, potato-digging operation has been mechanized with the introduction of potato diggers. The machine may be manually operated or power operated such as animal-drawn potato digger (Fig. 1), tractor-drawn potato digger (Fig. 2), potato digger shaker and potato digger elevator (Fig. 3). The potato digger elevator consists of a shovel, rod chain conveyor, gearbox and two gauge wheels. The machine digs one or two ridges of potatoes at a time and picks up the soil-potato mass over the rod chain conveyor. Agitating sprocket, of this conveyor oscillates the rod chain and separates the soil. The tubers with no or very little soil drop out on the ground in a row behind the machine, which are later collected manually. These machines are commercially available and are used widely in the northern states of India. Most of these machines are 2 row machines, but 1-row and 2-row both types of diggers are also available. The machine can cover 1.5-3.0 ha/day at forward speed of 2.0-3.0 km/h. Potatoes are easily bruised or skinned but are less susceptible when fully mature than when immature.

Groundnut digger shaker

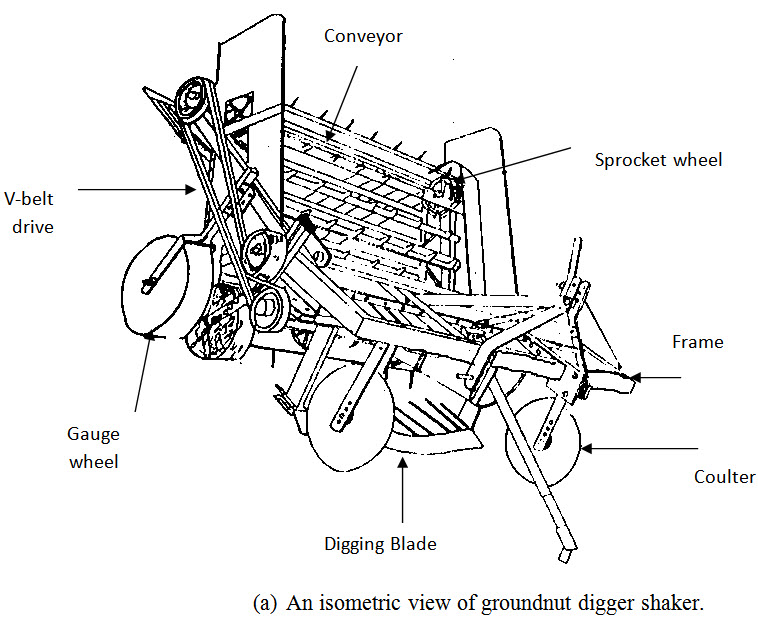

The combination digger shaker comprises of single piece curved blade with extension rods welded at the rear, two disc coulters and an endless chain type pick-up elevator-cum-shaker conveyor (rattler) having spiked rakes bolted to the chains. Power transmission of the digger consists of a gear box, a cross drive shaft, V-belt & pulleys and driving sprockets mounted on a shaft supported over members of the frame. Blade, shanks, coulter forks and gear box are all clamped to a rectangular tool bar to which are also welded two inclined side members on which the sprocket drive shaft is supported. Roller chains of the shaker conveyor are supported over two idler sprockets at the front end. Gauge wheels are also provided to adjust & maintain the desired working depth. Front portion of the shaker conveyor can be adjusted up or down with the help of a hand lower chain. The width of cut is 1.22 m.

Principle of operation: The blade digs the crop from a 1.2 meter wide strip. The vines are picked up and lifted by the shaker conveyor that follows blade. The soil adhering to the roots and pods is shaken off at the conveyor and the vines are dropped at the back in the form of a fluffy windrow. The vines are laid up-side down, thus exposing the pods effectively to the sun. After one or two days sun drying the vines are gathered manually and hauled to a central place for threshing. In foreign countries, a combine is used for these operations.

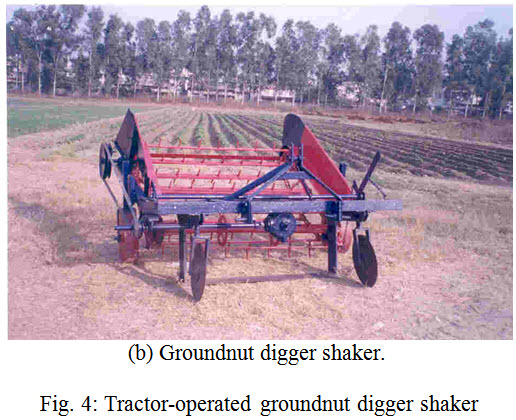

Tractor PTO operated groundnut digger shaker is quite popular in northern India far harvesting groundnut. The machine consists of a blade, elevator-cum-pick up reel, power transmission system, windrower attachment and fenders, gauge wheels and coulters (Fig. 4). The front end of pick up-cum-elevator reel is adjustable in accordance with depth of working of blade. It digs out the plant along with groundnut. The material is moved over the conveyor; the soil is loosened and removed. It has been designed to suit a tractor of 30 hp or more and is being operated by PTO shaft of the tractor. The digging shovel may be either of pointed type or conveying cutting edge type. The width of digging shovel ranges from 50-60 cm. This machine has an average output of 0.27 ha/h. The forward speed of digger is kept between 2.4-3.0 km/h. In order to pick and gather the tubers dropped in a windrow behind the digger, nearly 10-12 workers are required for continuous working of the digger.

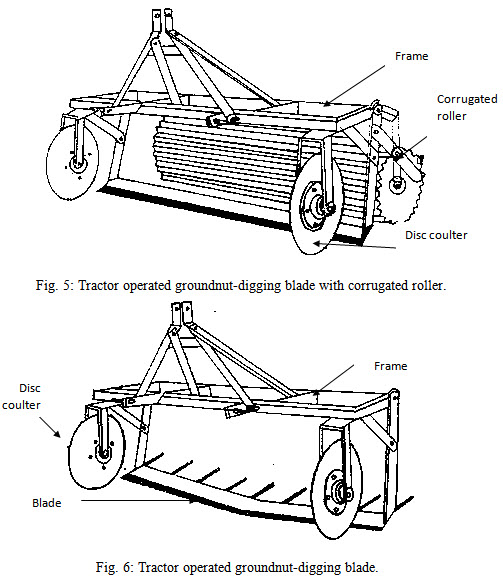

Groundnut digger blades with corrugated roller at rear (Fig. 5) are also used in medium and heavy soils where the corrugated roller helps in crushing the clods. This helps in easy picking of groundnut tubers. Another simple groundnut digger blade (Fig. 6) is also used in light soil where clod formation is not much. Loose soil falls through the extension rods behind the blade and groundnut tubers are left over the soil for easy picking and gathering.