Site pages

Current course

Participants

General

MODULE 1. PRINCIPLES AND TYPES OF CUTTING MECHANISM

MODULE 2. CONSTRUCTION AND ADJUSTMENT OF SHEAR AND...

MODULE 3. CROP HARVESTING MACHINERY

MODULE 4. FORAGE HARVESTING, CHOPPING AND HANLING ...

MODULE 5. THRESHING MECHANICS, TYPES OF THRESHES, ...

MODULE 6. MAIZE HARVESTING AND SHELLING EQUIPMENT

MODULE 7. ROOT CROP HARVESTING EQUIPMENT

MODULE 8. COTTON PICKING AND SUGARCANE HARVESTING ...

MODULE 9. PRINCIPLES OF FRUIT HARVESTING TOOLS AND...

MODULE 10. HORTICULTURAL TOOLS AND GADGETS

MODULE 11. TESTING OF FARM MACHINES, RELATED TEST ...

MODULE 12. SELECTION AND MANAGEMENT OF FARM MACHIN...

LESSON 24. HARVESTING OF FRUITS FROM TALL TREES

The Coconut Palm

The coconut palm grows luxuriantly in India. India ranks second in the world in production of coconuts with the Philippines ranking first. The coconut palms are grown in the coastal areas of Maharashtra, Karnatka, Tamil Nadu, Odisha, Andhra Pradesh and Kerala. Under suitable conditions the coconut palm yields more than 200 nuts annually throughout its life of about 80 years. Three-fourths of the production in India is consumed as tender nuts, particularly in summer months. While coconuts are harvested the year around, but there are seasons of higher yields such as in 1st quarter of year 30% of crop is harvested, in 2nd quarter of year about 40% and in 3rd and 4th quarter of year only 30% of crop is harvested. The coconut trees are very tall trees. Mostly harvesting of coconuts is done using long bamboo poles through which nuts fall on the ground and then they are collected manually. Mechanical harvesting of palm trees is still done using buckets. A lot of work is going on in improvements of mechanical harvesting, husking, shelling, shredding, and drying.

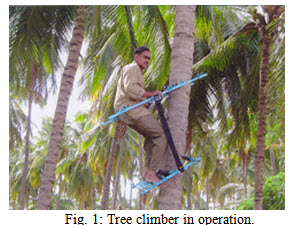

Tree climber

In order to harvest coconut and arecanut at faster rate with proper safety, TNAU, Coimbatore center has developed a tree climber. The developed tree climber is free from any accident risk during its operation.

Constructional Details: The climber made of M.S. square pipe consists of two components. Adjustable belts connect the components. The upper component is provided with a seating arrangement and lower component is having provision for holding the foot. The rubber cushioning is provided at the portion of frames, which comes in contact with tree to avoid any damage of tree.

Performance of machine: By standing on the lower component, the upper component can be moved up or down over the tree (Fig. 1). The operator can safely climb a tree of 10 m height in 1.5 min without any risk.

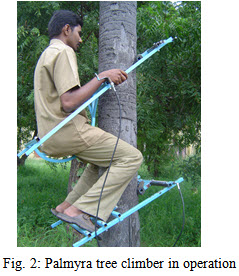

Manual climbing device for Palmyra

Harvesting of palmyra fruits and neera is done by trained labour who climb the 60 foot tree, which is an accident prone operation demanding a strenuous effort. Moreover skilled tree climbers are rarer nowadays because of the drudgery involved in this operation. A coconut tree climbing device was developed successfully at TNAU Coimbatore during 2006, which is a simple device facilitating any untrained person to safely climb the coconut trees and do the required operations. However unlike coconut trees, the variation in the girth of palmyra tree from base to top is considerable and hence the developed device was re-designed so as to adjust the frame width on-the-go to correspond with the girth of the tree at each height. To accommodate a wider girth range, the mechanism was improved by providing two number of sliding inclined bushes, which provide V shape to grip on the tree. Simple cranks and flexible shafts provided for easy adjustment (Fig. 2). Adjustment is now very easy, but the range of girth variation could not be accommodated yet. The average time taken for climbing up and down was about 6.30 min for a 40 feet tree with time for fixing and removing the device on the tree being 4 min.

Mechanized Harvesting of Palm Fruits

Mechanized harvesting of palm fruits not only reduces the working time of harvesting but also improves the quality of fruits and reduces harvesting loss. The machine improves the working condition of person engaged in harvesting of fruits in terms of safety and comfort. The machine requires two men one tractor driver and another platform operator. The machine consists of a crane, telescopic arm, chute for fruit, self lever along x and y-axis, harvest body, balancing axle, open and closed platforms, moving blade, fixed blade, displacement controls, working lever and working piston. The machine is brought near to the palm tree and platform is raised to the desired height. Fruits are cut using fixed and movable blades at the top of telescopic arm. Then, platform is lowered and machine is moved to next palm tree and fruits are harvested repeating the above steps. Once the container is filled with palm fruits, unload the container. The performance of machine can further be improved by suitable modification in the design. The oscillating axle device can be revised to reduce soil compaction and to reduce the angle of inclination when machine passes through depressed area, holes and other obstacles. The hydraulic system can be improved to reduce the time for lowering and raising the platform.

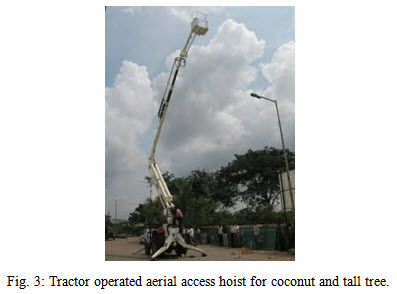

Aerial access hoist for coconut and tall tree crop management

All existing tools and devices involve the operator to climb up the tree for harvesting and carrying out other management practices at the crown. Farmers who own large areas are interested in having a system which can elevate a person up to the tree crown by a portable aerial access platform. The existing aerial access platforms are having the following limitations.

(i) The access is vertically upward and not in the side wards

(ii) The machines are designed to operate by resting on firm surface

(iii) Most machines have very wide stabilizing legs which cannot be operated under field conditions.

(iv) Require long time for setting up and operating

Keeping the above constraints in view and after a thorough study of the planting pattern and space requirements the following technical requirements of a tractor mounted aerial access hoist were formulated.

|

Lifting capacity |

120 kg |

|

Platform size |

1000 x 700 x 1000 mm |

|

Working height |

16 m |

|

Platform access height from the ground |

15 m |

|

Platform outreach |

6 m |

|

Rotation/slewing angle |

360 degrees |

|

Stabilizer |

Hydraulically operated 4 nos. to provide absolute stability |

|

Power |

PTO of tractor, with exclusive hydraulic system and controls |

The design of individual sub systems and structure were done by M/s Vanjax, Chennai in collaboration with TNAU Coimbatore. Since this is the first machine of its kind which was tractor mounted, the method of mounting the hoist to the tractor and the limitations of the PTO drive were taken into account during the design (Fig. 3). A full length chassis was extended from the front of the tractor to the rear and bolted to the tractor chassis. This forms the support for the hoist and provided for mounting of all stabilizers. The entire weight of the hoist and moments were transmitted through the chassis to the stabilizers without transferring to the tractor chassis. The following tests were conducted for confirming the performance.

(i) Reach test without load

(ii) Reach test with load

(iii) Preliminary field test

The results of preliminary field evaluation shows that the tractor mounted aerial access hoist can be taken into the coconut field and four trees can be accessed from a single position. The time required for locating unit and operating stabilizers was 1 min. The time required for positioning against a tree of 10 m height was 2 min. Suitable safety devices were incorporated to ensure stability of the hoist. The positioning of the operator platform can be done by the operator himself using electro hydraulic controls.

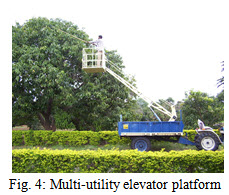

Multi-utility elevator platform

Close aerial access to the fruits provides better control on the harvesting operation thereby reducing the damage to fruits and tree branches. The tractor operated elevator attachment is a versatile and reliable worker-positioning platform from which the delicate fruits can be picked up or harvested very safely and efficiently from the trees (Fig. 4). The positioning is adjustable by the operator himself both vertically and horizontally. Hence selective picking of superior quality fruits with negligible fruit drop and higher capacity of harvesting fruits is achieved as compared to the traditional methods. Used for safe and efficient harvesting of fruits. Also used for efficient spraying, pruning, training of orchard crops.

Specifications

Capacity of fruit harvesting (kg/hr) : 70 -150

Maximum height of harvesting (cm) : 762

Load bearing capacity (kg) : 200

Power requirement : Hydraulic system of any tractor

Labor requirement : Two including tractor driver

Tractor mounted telescopic hoist

The tractor-mounted hoist can be used in orchards and plantation crops for trimming, pruning, plant protection and harvesting operations. It consists of two square aluminium ladders, each made of U-section as frames and round hollow pipes as cross members (Fig. 5). The U-sections of the outer ladder are inward facing while U-sections of the inner ladder face outward, sliding one over the other. Two wire ropes are provided, which are driven with a hydraulic motor. The motor, while running in clockwise direction helps in lifting the inner ladder and while running in anti clockwise direction, lowers the inner ladder down. A support frame fitted to the platform on the top end of the inner ladder helps as a safety frame. While transporting, the hoist can be folded and tilted to horizontal position over tractor canopy.

Specifications

Maximum height of platform (mm) : 9500

Minimum height of platform (mm) : 5500

Plant to plant spacing (m) : 10

Field capacity, min/tree : 30