Site pages

Current course

Participants

General

MODULE 1. PRINCIPLES AND TYPES OF CUTTING MECHANISM

MODULE 2. CONSTRUCTION AND ADJUSTMENT OF SHEAR AND...

MODULE 3. CROP HARVESTING MACHINERY

MODULE 4. FORAGE HARVESTING, CHOPPING AND HANLING ...

MODULE 5. THRESHING MECHANICS, TYPES OF THRESHES, ...

MODULE 6. MAIZE HARVESTING AND SHELLING EQUIPMENT

MODULE 7. ROOT CROP HARVESTING EQUIPMENT

MODULE 8. COTTON PICKING AND SUGARCANE HARVESTING ...

MODULE 9. PRINCIPLES OF FRUIT HARVESTING TOOLS AND...

MODULE 10. HORTICULTURAL TOOLS AND GADGETS

MODULE 11. TESTING OF FARM MACHINES, RELATED TEST ...

MODULE 12. SELECTION AND MANAGEMENT OF FARM MACHIN...

LESSON 26. VEGETABLE HARVESTING TOOLS AND EQUIPMENT

Potato harvesting machines are widely used in India and elsewhere also. Harvesting of green peas, beans etc. is widely accepted in countries like USA and Australia. Considerable progress has being made in developing harvesters for many other vegetable crops. But their acceptance rates are different and depend upon the problems involved and potential economic gain from mechanization.

Tomato Harvesting: Tomato is an important vegetable crop after the potato. Some of the tomato crop is needed for processing to make various products and other is used as fresh vegetable. Tomato harvesting machines are generally once over machines. Selective picking type of machines is not popular. In a once over machine, the following unit operations are involves.

(i) Uprooting or cutting of the plant stem at or just below the ground surface

(ii) Conveying the entire plants into the machine

(iii) Detaching the fruit from the plant by shaking

(iv) Cleaning the detached fruit with blowers

(v) Manual separation of ripe tomatoes from green ones, clods and other debris, and

(vi) Conveying sorted fruits into bins or a special trailer.

Usually vine is cut with the help of a pair of stationary knives or a special sickle-bar type of cutter bar. Two overlapping, counter rotating, powered disc blades can also cut it. Another arrangement has a rotating square bar that operates beneath the ground and uproots the plants. Conveying of plant is accomplished by either rubber covered rod-link chains employed as elevating conveyor or by using two draper-type elevating conveyors in series, with an arrangement between the conveyors that removes dirt and loose tomatoes onto special sorting belts.

Fruit detachment from plant is accomplished by shaking. In one arrangement the vines are carried on a chain and rod type conveyor that has sections oscillated either in a fore-and-aft direction or vertically. In another arrangement, shaking units have continuously moving chains spaced laterally a few centimetres apart with vertical fingers that move the vines towards the rear as the entire assembly is vibrated horizontally in a fore-and-aft direction. Since the tomatoes are quite susceptible to impact damage, the shakers and conveyors must be designed to minimize drop distances and impact force resulting from fruit inertia. It is very important to provide cushioning at all critical points to avoid fruit damage.

Other vegetable harvesting machines: Green pea harvesting machine cut the entire plant near the ground with an oscillating cutter bar and load them into trailer or truck pulled either behind or at side of the machine. The crop is then handled to a processing plant. Harvesting of beans has become easier with the development of varieties that mature a large percentage of the beans at one time. Due to this it is possible to harvest entire crop in one operation. These machines usually harvest 2 to 3 rows each time. The leaves and stems are grasped between rollers and the beans are separated from the plants.

A harvester which is mounted on a large trailer or tractor chassis harvests crops like cabbage and lettuce. It moves slowly through the field as the vegetables are cut by hand and placed onto the conveyor belts. The belts extend out on either side of the machine to bring the hand cut vegetables to a control location. They are finally loaded into trucks or trailers. A great difficulty is forced in harvesting this type of crop, because it has to handle wide range of head sizes and considerable variation in alignment of plants along the row. It causes variation in alignment of plants along the row. Therefore, obtaining a satisfactory cut is a problem.

Cucumber harvesting is done by machines, which have platform on which pickers are carried. Mechanical harvesters have been developed in the USA to harvest the cucumber crop. The machine gathers the cucumbers from the vine and leaves the vine practically undamaged. In order to harvest the crop with machines due care has to be taken during planting of crop, so that vine must be in condition for easy machine harvesting.

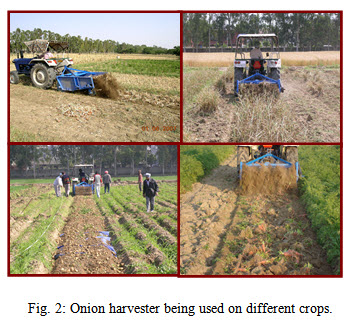

Bhindi plucker

It is used for plucking of bhindi (ladies finger) from plant. The tool is ergonomically designed. The plucker consists of two arms hinged together, cutting blades joined to open ends of arms and two rings joined to the arms (Fig. 1). The blades are made of medium carbon steel or low alloy steel, hardened and tempered to suitable hardness. Panicles are cut individually using this tool. The operator is spared of drudgery, discomfort and itching to skin of his hands, which are associated with conventional method of manual plucking without any aid. It fits in to the hand properly with the help of two rings, one over thumb and another over index finger. Force to cut the pedicle is exerted by pressing these two fingers against each other. Pedicle is sheared between two straight blades, one of which is notched for better grip.

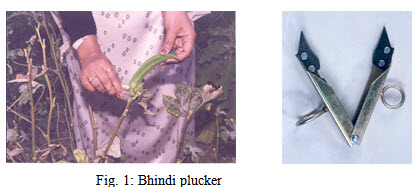

Onion Harvester: Onion is another important vegetable crop, which has a lot of consumption the world over. Mechanical harvesting of such crop is required for timely vacating of fields. The principal functions of mechanical onion harvester are digging, elevating, topping, and bagging or bulk handling. Onion harvesting can be successfully carried out with the help of modified potato harvesting machine. Some commercially available machines lift the onions with a modified potato harvester before they are topped. Toping is done with the help of pairs of parallel, counter rotating spiral rolls, which orients the onions and pulls the tops downward between the rolls. Rotating blades just below the rolls remove the tops leaving a short stem on each onion. The spiral rolls deliver the onions to an elevator. The onions are undercut with blade about three weeks prior to harvest to ensure that the tops get dry enough for the rolls to operate effectively.

Tractor mounted onion harvester-cum-elevator

Onion harvester-cum-elevator was developed for digging onion and other root crops. It consist of a digger blade made from high carbon wear resistant steel. The width and thickness of the blade is 1144 mm and 16 mm. The blade is mounted on the machine at an angle of 20o with the horizontal. An elevator chain conveyor has been attached behind the blade. The spacing between the MS rods used for the fabrication of the elevator conveyor is 20 mm. The slope of the elevator conveyor was kept at 18o. Two oval agitators were provided in the conveying system for separation of soil particles from the onion bulbs. The power to the elevator conveyor has been provided through a gear box (speed ratio 5:27). Two coulter discs are provided in front of the blade at the outer ends, which helps in easy slicing and lifting of soil by the blade. A vie of machine working of digging different crops is given in Fig. 2 and performance results in Table 1. The field capacity of the machine is 0.28, 0.24, 0.21 and 0.21 ha/h for digging carrot, potato, garlic and onion crop respectively when operated at a speed of 2.78, 2.41, 2.10 and 2.10 km/h whereas respective damage is 1.98, 1.92 1.22 and less than 1.0% respectively. The saving in labour ranged from 62 to 71%. The performance of the machine was highly satisfactory for digging these crops except excessive soil coming over the conveyor. Saving in cost of operation and labour for harvesting onion, carrot and, garlic was 52.28, 46.71, 52.28% and 69.05, 59.29 and 69.05% respectively as compared to manual harvesting. There was no saving in labour and cost in case of potato digging as compared to digging of potato using potato digger. However due to more use per year the overall cost of operation will reduce.

Table 1: Performance results of root crop digger cum elevator for digging carrot, onion, garlic and onion crops.

|

S. No. |

Parameter |

Onion harvester |

Farmer’s Practice |

||||

|

|

|

Onion |

Carrot |

Garlic |

Potato |

Onion |

|

|

Location of trials |

PAU Research Farm |

- |

|||||

|

Variety of crop |

Pb Red Round |

Doctor Seed Red |

Pb Garlic No.1 |

Kufri Pukhraj |

Harvesting of onion, carrot and garlic manual or using tillers and of potato using potato digger. So comparison is done with manual and of latter with digger. |

||

|

Age at time of harvesting, days |

142 |

100 |

160 |

90 |

|||

|

Operational speed of the machine, km/h |

2.11 |

2.78 |

2.05 |

2.41 |

|||

|

Machine capacity, ha/h |

0.21 |

0.28 |

0.21 |

0.24 |

|||

|

Effective digging width, cm |

105 |

105 |

105 |

105 |

|||

|

Percent of exposed bulbs |

99.0 |

97.3 |

97.6 |

96.4 |

|||

|

Percent of cut bulbs |

<1.0 |

1.95 |

1.22 |

1.92 |

|||

|

Field efficiency, % |

|

|

|

|

|||

|

Fuel consumption, l/h |

4.5-5.0 |

4.5-5.0 |

4.5-5.0 |

4.5-5.0 |

|||

|

Yield, q/ha |

126.7 |

356.0 |

190.0 |

316.2 |

|||

|

Labour requirement, (man-h/ha) a) For harvesting b) For collection c) Total |

4.80 150.0 154.8 |

3.59 200.0 203.6 |

4.86 150.0 154.9 |

4.13 220.0 224.2 |

500 |

||

|

Cost of operation, Rs./h |

1002.00 |

1419.80 |

1002.00 |

1428.00 |

- |

||

|

Cost of operation, Rs/ha |

4772.00 |

5328.00 |

4772.00 |

5950.00 |

10000.00 |

||

|

Saving in cost of operation,% |

52.28 |

46.71 |

52.28 |

0.00 |

|

||

|

Saving in labour, % |

69.05 |

59.29 |

69.05 |

0.00 |

|

||

|

Breakdown of equipment |

Nil |

||||||

|

Remarks of the farmers |

Machine in development stage |

||||||