Site pages

Current course

Participants

General

MODULE 1. PRINCIPLES AND TYPES OF CUTTING MECHANISM

MODULE 2. CONSTRUCTION AND ADJUSTMENT OF SHEAR AND...

MODULE 3. CROP HARVESTING MACHINERY

MODULE 4. FORAGE HARVESTING, CHOPPING AND HANLING ...

MODULE 5. THRESHING MECHANICS, TYPES OF THRESHES, ...

MODULE 6. MAIZE HARVESTING AND SHELLING EQUIPMENT

MODULE 7. ROOT CROP HARVESTING EQUIPMENT

MODULE 8. COTTON PICKING AND SUGARCANE HARVESTING ...

MODULE 9. PRINCIPLES OF FRUIT HARVESTING TOOLS AND...

MODULE 10. HORTICULTURAL TOOLS AND GADGETS

MODULE 11. TESTING OF FARM MACHINES, RELATED TEST ...

MODULE 12. SELECTION AND MANAGEMENT OF FARM MACHIN...

LESSON 28. INTRODUCTION TO FARM MACHINERY TESTING, TYPES OF TESTS, TESTING PARAMETERS

Protocol for Testing of Agricultural Machinery

Farm machinery testing involves the determination of:

-

Functional performance characteristics of machine

-

Power requirement of a particular component of whole machine

-

Durability

-

Wear testing of some of soil engaging tools

-

External forces such as soil forces acting on soil engaging tools, and

-

Stresses developed in different parts of machine due to static or dynamic loading.

Farm machinery manufacturers are very much concerned to know the above details about their products. Tests conducted by various state and central agencies and institutions involve the functional performance tests, power measurement, durability test, wear test and forces acting on tillage tools. Proper planning and careful execution of tests is extremely important. Wherever feasible, tests may be designed to permit statistical analysis of results to accelerate durability tests in the laboratory and functional tests in the field.

Testing of farm machines is useful to both buyers i.e. farmers as well as to the manufacturers. Testing encourages improvement in quality and functional suitability. Testing of machines helps farmers in proper selection of implement, suitable power source and required adjustments in machines. It helps manufacturers in commercial publicity of product, better design and sales promotion. Comparable data for similar machines is available to manufacturers, which help them in improving the design of their product.

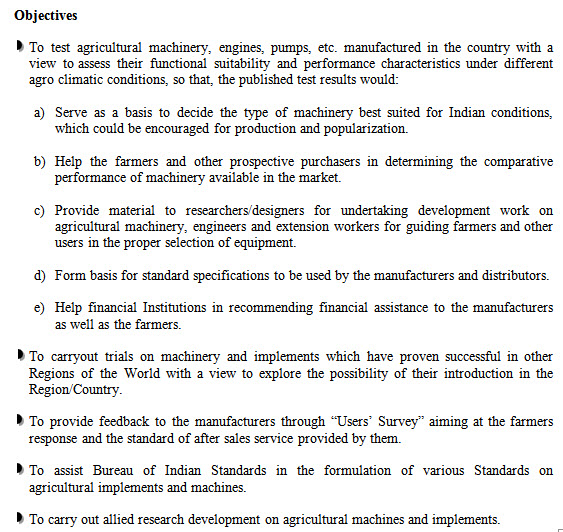

Different countries have established various organizations and institutions, which test the farm equipment, supplied by the manufacturers and submit the confidential reports. The foremost duties of such organizations are to first develop the standard test codes for different types of farm machines, which forms the basis for testing of the machines. Government of India has established Bureau of Indian Standards, which does the job of preparing standard test codes. Other countries in the world have also similar organizations; some of them are Nebraska Testing Center in USA, British Standards Institutions London, in U.K., Organization for the Economic Co-operation & Development (O.E.C.D.), Paris and International Organization for Standardization (ISO) etc.

Bureau of Indian Standards, Manak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi has develop standard codes for agricultural tractors and power tillers, agricultural produce processing equipment, crop production equipment, farm transport equipment, forestry and plantation crop machinery, harvesting and threshing equipment, horticultural equipment, soil working equipment and sowing, fertilizer and manure application equipment.

International Organization for Standardization (ISO) was formed in 1947 with headquarter at Geneva, Switzerland to promote the development of standardization and related activities with a view to facilitate international exchange of goods and services and to develop cooperation in the share of intellectual, scientific, technological and economic activities. The organization consists of Technical Committee (TC) and Technical Advisory Group (TAG). ISO comprises of National Standard Bodies of 91 countries including India, which is represented by the Bureau of Indian Standards (BIS). The tests are conducted by the Farm Machinery Training and Testing Institutes under the jurisdiction of Ministry of Agriculture, Government of India. Currently, there are four institutes located at Budni in Madhya Pradesh, Hissar in Haryana, Anantpur in Andhra Pradesh and Vishwananth Chariali in Assam. The development of International Standards on quality Management systems led to ISO 9000 series of standards in 1987. In all following six standards were issued:

ISO 8402 : Quality Management and Quality Assurance – Vocabulary

ISO 9000 : Quality Management and Quality Assurance – Guidelines for selection And usage

ISO 9001 : Quality System Model for quality assurance in design, development, Production, installation and servicing

ISO 9002 : Quality System Model for quality assurance in production, installation and servicing

ISO 9003 : Quality System Model for quality assurance in final inspection and test

ISO 9004 : Quality Management and quality system elements – guidelines