Site pages

Current course

Participants

General

Module 1. Introduction about design and developmen...

Module 2. Study of special design features of trac...

Module 3. Study of basic design parameters for tra...

Module 4. Selection of different mechanical power ...

Module 5. Study of tractor steering and suspension...

Module 6. Design and analysis of tractor hitch sys...

Module 7. Design of a tractor hydraulic system

Module 8. Study of electrical, electronics and gui...

Module 9. Ergonomics, controls and safety features...

Module 10. Tractor testing

Module 11. General revision

Appendices & References

Lesson 28. Cost estimation and selection of tractor

Machinery and equipment especially tractors are major cost items in farm businesses. Larger machines, new technology, higher prices for parts and new machinery, and higher energy prices have all caused machinery and power costs to rise in recent years.

1. Cost estimation

Farm machinery/Tractor costs can be divided into two categories: annual ownership costs, which occur regardless of machine use, and operating costs, which vary directly with the amount of machine use.

The true value of these costs is not known until the machine is sold or worn out. But the costs can be estimated by making a few assumptions about machine life, annual use, fuel and labor prices.

Ownership costs (also called fixed costs) includes depreciation, interest (opportunity cost), taxes, insurance, and housing and maintenance facilities.

Operating costs (also called variable costs) include repairs and maintenance, fuel, lubrication and operator/labor cost.

a. Fixed Costs :

Depreciation

Depreciation is a cost resulting from wear, obsolescence, and age of a machine. The degree of mechanical wear may cause the value of a particular machine to be somewhat above or below the average value for similar machines when it is traded or sold. The introduction of new technology or a major design change may make an older machine suddenly obsolete, causing a sharp decline in its remaining value. But age and accumulated hours of use are usually the most important factors in determining the remaining value of a machine.

Before an estimate of annual depreciation is calculated, an economic life for the machine and a salvage value at the end of the economic life need to be specified. The economic life of a machine is the number of years for which costs are to be estimated. It is often less than the machine’s service life because most farmers trade a machine for a different one before it is completely worn out. A good rule of thumb is to use an economic life of 10 to 12 years for most farm machines and a 15-year life for tractors, unless it’s known that machine will be traded sooner.

Salvage value is an estimate of the sale value of the machine at the end of its economic life. It is the amount expected to receive as a trade-in allowance, an estimate of the used market value if expected to sell the machine outright, or zero if plan is to keep the machine until it is worn out.

Note that for tractors, combines and forage harvesters the number of hours of annual use is also considered when estimating the remaining value. The factors were developed from published reports of used equipment auction values, and are estimates of the average “as-is” value of a class of machines in average mechanical condition at the farm. Actual market value will vary from these values depending on the condition of the machine, the current market for new machines, and local preferences or dislikes for certain models. There are many four methods for calculating the depreciation of any machinery

Straight Line Method: The annual depreciation charge is given by following relationship, Alternative method. Depreciated value after n-years may be expressed as:

![]()

Where,

P= Purchase price, Rs

S= salvage Value, Rs

L= Economic machine life, years

This method is the simplest, as it change on easily calculated, constant amount each year.

Declining-Balance Method: An uniform rate is applied each year to the remaining value (includes salvage value) of the machine at the beginning of the year. The depreciation amount is different for each year of the machines life. It is given by following relationship,

D= Vn –Vn-+1

![]()

Where,

D= The amount of depreciation charged for year (n+1)

N= The number representing the age of the machine in years at the beginning of the year in question

V= The remaining value at any time

x= The ratio of the depreciation rate used to that of the straight line methods. The value of x may be any number between 1 and 2.

Alternate Method: Depreciated value after n-years may be expressed as

![]()

And solvage value may be expressed as

S = (1-r)L *P

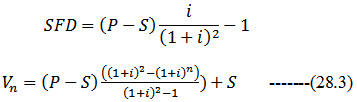

Sinking Fund Method: This method is generally used by engineering economist. This method considers the problem of the depreciation as one of establishing a fund which will draw compound interest uniformly annual payments to this fund are such a size that by the end of life of machine the funds their interest have accumulated to an amount which will purchase another equivalent machine.

Sinking fund annual payment (SFP) and the value at the end of year n are,

If x= 2, the method is called a double declining balance method permitted by IRS. For used machines the maximum rate is x= 1.5

Sum of the years-Digits Methods. It is given by following relationship,

![]()

Where, YD = The sum of years digits, (1+2+3+….+L)

N= The age of the machine is years at the beginning of the year.

An example problem will be used throughout this chapter to illustrate the calculations. The example is a 50-PTO horsepower diesel tractor with a list price of Rs. 600000. An economic life of 15 years and an interest rate of 8 % is assumed. The tractor is expected to be used 400 hours per year.

For the 50-hp (37.3 kW) tractor with 400 hours of annual use in the example, the salvage value after 15 years is estimated as 23 % of the new list price:

Salvage value = current list price x remaining value factor =600000 x 23%

= 138000

Total depreciation = purchase price - salvage value =600000 – 138000

=462000

Annual Depreciation (considering 15 years life of the tractor = Rs. 30800

Interest:

If money is borrowed to buy a machine, the lender will determine the interest rate to charge. But if you use your own capital, the rate to charge will depend on the opportunity cost for that capital elsewhere in your farm business. If only part of the money is borrowed, an average of the two rates should be used. For the example we will assume an average interest rate of 8%.

Interest is calculated on the average investment of the machine taking into consideration the value of the machine in first and last year. It is given by following relationship,

![]()

Where, i= % rate of the interest

H = working hours per year, h

Annual Interest paid = 738000/2 x 8% = Rs. 295200

Taxes, insurance, and housing (TIH):

These three costs are usually much smaller than depreciation and interest, but they need to be considered. There is no taxes on ownership of farm machinery but recently taxes are put on tractor. Insurance should be carried on farm machinery to allow for replacement in case of a disaster such as a fire or accident. If insurance is not carried, the risk is assumed by the rest of the farm business. There is a tremendous variation in housing provided for farm machinery. Providing shelter, tools, and maintenance equipment for machinery will result in fewer repairs in the field and less deterioration of mechanical parts and appearance from weathering. That should produce greater reliability in the field and a higher trade-in value. An estimated charge of 1.0 % of the purchase price is suggested for taxes, insurance and housing costs.

Annual TIH = 0.01 x purchase price

For our tractor example, these three costs would be: TIH = 600000x 1% =6000

Total ownership cost

The estimated costs of depreciation, interest, taxes, insurance and housing are added together to find the total ownership cost. This is almost 10 %t of the original cost of the tractor.

Total ownership cost = 30800 + 29520 + 6000

=Rs. 66320 per year

If the tractor is used 400 hours per year, the total ownership per hour is:

Ownership cost per hour = 66320 / 400 hours

= Rs. 166 per hour

b. Operating Cost

Fuel

Fuel costs can be estimated in two ways. One method is that how many drums of diesel are consumed in a year. The total numbers of litres can be divided by 400 hours and per hour diesel consumption of tractor can be calculated. If fuel meter is attached with the tractor fuel line then exactly for each operation, fuel consumed per hour can be measured.

Average fuel consumption (in gallons per hour) for farm tractors on a year-round basis without reference to any specific implement can also be estimated with these equations:

0.14 x maximum PTO horsepower for diesel engines

For our 50-horsepower diesel tractor example: Average diesel fuel consumption = 0.14 x50 horsepower = 7 litres/hour

Average fuel cost per hour = 7 l/hour x Rs. 50/litre =Rs. 350/hour

Lubrication

Surveys indicate that total lubrication costs on most farms average about 15 % of fuel costs. Therefore, once the fuel cost per hour has been estimated, you can multiply it by 0.15 to estimate total lubrication costs.

For our tractor example, average fuel cost was Rs. 350 per hour, so average lubrication cost would be:

Lubrication cost = 0.15 x 350 = Rs.52.5/hour

Repairs and maintenance

Repair costs occur because of routine maintenance, wear and tear, and accidents. Repair costs for a particular type of machine vary widely from one geographic region to another because of soil type, rocks, terrain, climate and other conditions. Within a local area, repair costs vary from farm to farm because of different management policies and operator skill.

The best data for estimating repair costs are records of your own past repair expenses. Good records indicate whether a machine has had above or below average repair costs and when major overhauls may be needed. They will also provide information about your maintenance program and your mechanical ability. Without such data, though, repair costs must be estimated from average experience.

Because the tractor in the example will be used about 400 hours per year, it will have accumulated about 6,000 hours of operation by the end of its 15-year economic life. As an estimate that after 6,000 hours of use, total accumulated repair costs will be equal to about 25 percent of its new list price. So, total accumulated repairs can be estimated to be:

Accumulated repairs = 0.25 x 600000 = Rs. 150000

The average repair cost per hour can be calculated by dividing the total accumulated repair cost by the total accumulated hours: Repair cost/hour= 150000 / 6,000 hours = Rs. 25/hour

Labor

Because different size machines require different quantities of labor to accomplish such tasks as planting or harvesting, it is important to consider labor costs in machinery analysis. Labor cost is also an important consideration in comparing ownership to custom hiring.

Actual hours of labor usually exceed field machine time by 10 to 20 percent, because of travel to and from field and the time required to lubricate and service machines. Consequently, labor costs can be estimated by multiplying the labor wage rate times 1.1 or 1.2. Using a labor value of Rs. 25 per hour for our tractor example:

Labor cost = 25 x 1.1= Rs.27.5/r

Different wage rates can be used for operations requiring different levels of operator skill.

Total operating cost

Repair, fuel, lubrication and labor costs are added to calculate total operating cost. For the tractor example, total operating cost is:

Total operating cost = 350 +52.5 +25+27.5 = 455 per hour

Total cost

After all costs have been estimated, the total ownership cost per year can be added to the operating cost per hour to calculate total cost per hour to own and operate the machine. Total cost per hour for our example tractor was:

Total cost = 166 + 455=Rs.621 / per hour

Implement costs

Costs for implements or attachments that depend on tractor power are estimated in the same way as the example tractor, except that there are no fuel, lubrication or labor costs involved.

Used Machinery

Costs for used machinery can be estimated by using the same procedure shown for new machinery. However, the fixed costs will usually be lower because the original cost of the machine will be lower. And repair costs will usually be higher because of the greater hours of accumulated use. Therefore, the secret to successful used machinery economics is to balance higher hourly repair costs against lower hourly fixed costs. If you misjudge the condition of the machine such that your repair costs are higher than you anticipated, or if you pay too high a price for the machine so that your fixed costs are not as low as you anticipated, the total hourly costs of a used machine may be as high or higher than those of a new machine.

Total Costs per Operation

Tractor costs must be added to the implement costs to determine the combined total cost per hour of operating the machine. Total costs in the example are:

Total cost = Rs. 621 per hour

Finally, total cost per hour can be divided by the hourly work rate in acres per hour or tons per hour to calculate the total cost per acre or per ton.

The hourly work rate or field capacity of an implement or self-propelled machine can be estimated from the effective width of the machine (in meter), its speed across the field (in kms per hour), and its field efficiency. The field efficiency is a factor that adjusts for time lost due to turning at the end of the field, overlapping, making adjustments to the machine, and filling or emptying tanks and hoppers.

2. Tractor Selection

It is vital to select the right options and optimise the way the tractor is operated to reduce costs. There are many choices when purchasing a tractor, especially in the area of transmissions, tyres and ballast. In some hp sectors there is even a choice of tractor size and weight as well. The starting point is knowing what the tractor is used for. Crucial questions include which tasks the tractor will perform, the hours taken on each task, the speed required and the implements to be used with it. Technology is becoming available to assist this task in the form of telematic systems which will be able to monitor how the tractor is used including engine load levels, hours by application, idle time and detailed fuel usage but these are not yet widespread and the purchaser must make judgements.

a. Power:

A suggested procedure for determining the minimum horsepower needed is:

Step 1: Determine the most critical field operation requiring implements with a high draft Ex. Mixing of rice straw in field using rotavator

Step 2: From past experiences, estimate how many days are available to complete this critical field operation Ex. Sowing of wheat after rice harvesting in narrow window period of about 15 days. If you plan to run a double shift be realistic about maintenance of the machine and the operator's personal time.

Step 3: Calculate the capacity needed in acres per hour in order to get the job done within the time allotted.

Step 4: Determine the size of implement needed.

Step 5: Select a tractor of proper size to pull the implement. To do this:

1. Determine draft of implement

2. Determine drawbar horsepower needed to pull implement,

3. Determine PTO horsepower needed.

Obviously the most important decision is to determine the size of the largest tractor. Normally the size of the largest tractor should be based on getting the critical, high-power jobs done within a specified time period. It follows, then, that as much use as possible should be made of the same tractor for other operations. Keeping in mind, also, that large tractors should be matched with large, heavy duty equipment to withstand the heavy loads created by the tillage implements. By the same, overloading a tractor can lead to serious mechanical failure. This can lead to down time and when a tractor is down, all work associated with that tractor stops.

Several terms are used by manufacturers to describe the capacity of their tractors. The basic definitions are:

Brake Horsepower - - The maximum power the engine can deliver without alterations. This power is particularly useful in sizing stationary engines.

Power-Take-Off-Horsepower (PTO) - - The power as determined at the power-take-off shaft of the tractor.

Draft (Drawbar) Horsepower - - The power transmitted by the tractor to the implement. The Nebraska Tractor Tests indicate that maximum drawbar horsepower will average approximately 85 percent of the maximum PTO horsepower for most of the tractors.

b. Two wheel drive, Front wheel assisted or Four wheel drive tractors

Tractors can be divided into 3 categories:

(i) Two-wheel drive (2-WD)

(ii) Front-wheel assisted (FWA) or unequal 4-wheel drive

(iii) Equal 4-wheel drive tractors (4-WD).

Each one of these tractors has different tire configurations and different ballast requirements. Two-Wheel Drive Tractors (2WD) are most commonly used in dry or upland farming situations and for transportation. They need 80% of the weight distributed over the rear axle to maximize traction. The biggest advantages of this type of tractor over other 4-wheel tractors are smaller turning circle, simplicity of design, fewer mechanical parts and lower purchase price. However, a 2WD tractor does not work at all well in wet, hilly and muddy conditions.

Front Wheel Assist (FWA) is commonly known as 4-WD or unequal 4-wheel drive. It is the most popular 4-wheel tractor in many parts of the countries worldwide. These tractors range in size from 5 HP - 240 HP (3.73- 178.96 kW) and are capable of delivering between 50-55% of the rated power at the drawbar. Typically, between 75 and 85% of the rated engine HP is delivered to a rear PTO (Power Take-Off) on any diesel tractor.

On a FWA tractor the front drive tires are smaller than the rear tires. These tractors require 40% of the weight distributed over the front axle and 60% over the rear axle. The major advantage in using this type of tractor is that it can deliver 10% more power to the ground at all 4 tires for the same fuel consumption, and thus has much better traction and flotation capabilities than 2-wheel tractors of the same size. FWA tractors normally cost about 15-35% more than the same horsepower two wheel drive tractor.

Equal Four-Wheel Drive (4WD) tractors have all four tires of equal size and range in size from 35 HP - 600 HP (26.1 -447.42 kW). This tractor type has the greatest power to weight ratio and can deliver between 55-60% of power at the drawbar. It is challenging to maneuver and often the size and expense makes these tractors impractical.

c. Fuel consumption

This parameter plays very important role in selection of a tractor. Specific fuel consumption g/kWh. is the measure of the number of grams of fuel used to produce 1 kW for 1 hour and appears in official tests as it allows you to compare tractors of different horsepower. This is measured at the engine flywheel, the PTO or at the drawbar depending on the type of test. The main tests are according to OECD standards and notably carried out by Nebraska Test Laboratory and CFMTTI, Budni.

Fuel Efficiency litres/unit of production. This measurement tells you how much work you achieve from a litre of fuel. It could be litres/hectare or litres/tonne and is by far the most meaningful figure to use as it takes into account the work done for an amount of fuel. The detail regarding saving of fuel by optimising tractor field efficiency is discussed in next chapter.

d. Hydraulic System

There are two different hydraulic systems available today – open and closed systems, however hybrid systems between the systems are also available.

Open Centre: Oil flows continuously round the tractor through all the valves. So oil is pumped all day whether you are using hydraulic functions or not. As a result there is a fuel cost in pumping all this oil.

Closed Centre - Pressure compensated: This system is a hybrid. Although oil is pumped all the time, it does not have to travel round the whole hydraulic system. When no oil is required, this system goes into a short circuit saving energy. Oil only flows to the valves that operate functions when required.

Closed Centre - Pressure and flow compensated: These are the most efficient of the systems. When there is no requirement for oil, the pump shuts down and produces no flow. This saves energy and so saves fuel. Oil is only pumped when required at the flow rate and pressure demanded by the service that is in operation becoming widespread.

e. Transmissions

For many power ranges there may be a choice of transmissions and there is a need to evaluate the type and duration of tasks as well as the speed of operation. Generally the cost increases with the degree of sophistication but so does the task and fuel efficiency, and certainly the comfort, if correctly matched. Synchronised transmission is often fitted to smaller lower specification tractors and is ideal for loader work especially if fitted with a power reverser allowing clutch-less direction changes. It is good for applications at fixed speeds e.g. fertiliser spreading and spraying will carry out tillage work but work rate will be lower compared to tractors that can shift on the move. Partial and full Power shift transmissions are good for field work as the transmission can perform multiple shifts under load and can better optimise work rate. Eco Shift transmissions are available to allow the tractor to run at maximum speed on the road at reduced rpm with fuel savings. Infinitely Variable Transmissions are the most versatile of all the transmissions with the ability to continuously vary the ratio to the engine power available and as a result deliver the highest work rate. These transmissions have the ability to reduce engine rpm, so saving fuel if the load reduces and operations where full power is not required will automatically be carried out at reduced rpm.

f. Power Take Off (PTO)

PTOs are available on a number of speeds and shaft configurations. These are:

• 6 spline shaft, 34.9 mm (1 3/8 in) nominal speed 540 rpm

• 21 spline shaft, 34.9 mm (1 3/8 in) nominal speed 1000 rpm

• 20 spline shaft, 44.5 mm (1 ¾ in) nominal speed 1000 rpm

Typical speeds are 540, 540E, 1000 and 1000E. The economy speeds are provided for lighter applications that allow nominal pto speed to be reached at reduced engine rpm, saving fuel. The use of an economy pto vs full speed pto typically will result in an 18% fuel saving. So if you have pto applications for significant hours, economy speed pto’s should be specified and used if possible.

g. For custom hiring or self

Tractor is purchased for operation on custom hiring operation or purchased by the cooperative societies of the village, then tractor fitted with telemetry and GPRS will be more suitable. Signal of its operation and some engine parameters will be sent through SMS during the operation of tractor in remote areas. This data may be useful for better management of tractor fleet.

h. Clutch type

There are two types of clutch available – dry and oil cooled. Dry clutches suffer some wear every time they are disengaged and engaged. This means that a dry clutch will wear out eventually and require replacement but may be more economical for low hour usage. An oil cooled clutch virtually eliminates this wear so is better suited to applications that have frequent clutch use e.g. loader work.

i. Suspension and comfort options

As well as improving comfort and allowing greater productivity front axle suspensions can improve traction in the field effectively increasing usable power.

j. Selection of Tyres

The selection of tyres is one of the most important considerations. Even if you optimise the specification of your chosen tractor in all areas but get tyre selection wrong, you will not be able to apply power to the ground effectively. When selecting tyres, you must ensure they have adequate carrying capacity for the applications you carry out and the implements used. The only real way to determine this is to weigh the tractor with the implement and from that, you can determine the additional weight the implement adds to the tractor axles. The markings of load index and speed symbol are also shown on the side wall of the tyre and tell you how much weight the tyre will carry at what speed. The figures must be looked up in a tyre book.

Tyre choice should be made in the following order:-

1. Choose the tallest tyres that will fit the tractor. Taller tyres give a longer footprint and reduce rolling resistance in the field. The wall of soil that the tyre has to climb up stays the same width but the larger footprint reduces sinkage, so reduces rolling resistance. This improves efficiency.

2. Choose the widest tyres that are compatible with your applications. A wider tyre will have a larger footprint and reduce ground pressure. It does not necessarily reduce rolling resistance as taller tyres do. Although the height of the soil wall is reduced, it is also wider.

3. Choose tyres of adequate carrying capacity for your most demanding application. If cropping dictates you have to use a small narrow tyre, be aware that the tyre may not be capable of transmitting the full power available or carrying the full weight of the tractor plus any imposed load. So if you have a tyre that say fits your potato operation, it may not be adequate for general cultivation work, transport with heavy trailers and large mounted implements.

4. Choose a tyre that is adequate for the tractor hp and operate at proper pneumatic pressure according to the operation.