Site pages

Current course

Participants

General

MODULE 1. Introduction to mechanics of tillage tools

MODULE 2. Engineering properties of soil, principl...

MODULE 3. Design of tillage tools, principles of s...

MODULE 4. Deign equation, Force analysis

MODULE 5. Application of dimensional analysis in s...

Module 6. Introduction to traction and mechanics, ...

Module 7. Traction model, traction improvement, tr...

Module 8.Soil compaction and plant growth, variabi...

LESSON 1. HISTORY OF TILLAGE

1.1. INTRODUCTION

Tillage means the preparation of the growth zone in the soil (about 10 to 90 cm of the top layer of soil) for plant development. As large areas of the surface of the earth are subject to tillage, man has tried to ease the cumbersome and time-critical work of tillage and developed machines which allow in most places of the world to perform this task with ease and efficiency.

1.2. GENERAL IMPORTANCE OF TILLAGE OPERATIONS

The task of tillage is to prepare soils for productive use. Usually tillage is limited to the arable layer of soil, which contains organic matter and where plant life actually can occur. Tillage has to be performed to clear virgin soils of plants and animals for agricultural use. Furthermore, it must be performed to bring the seedlings into the soil and procure for them a good environment for further development.

Another objective of tillage is to control weeds and animals living in the soil, such as mice or slugs. This is, compared to the use of chemical means, an energy and time consuming

way to control pests. Another important point is surface leveling because most operations in mechanized agriculture depend on level surfaces. Irregularities in the soil niveau may be caused by traffic on the soil, harvesting or climatic effects. Together with this goes the need to distribute clods and porosity according to plant need. The seeds should be covered by small clods for protection while around the seeds, fine soil should prevail. Under the seeds, porosity must not be too high, while smaller and larger clods should give structure to the soil. Producing this distribution of smaller and larger clods (stratified seedbed) is one of the main objectives of primary tillage.

Producing fine soils for the environment of the seedling and the structure of the seedbed is the main objective of secondary tillage and seedbed preparation. Warming up the soil and bringing air to deeper layers stimulates life in the soil. At the same time, loosening makes it easier for plant roots to penetrate into deeper soil layers. An optimum porosity will also facilitate the infiltration of air and water for the plant roots, and the ascention of water from deeper soil layers during dry periods. Loosening the subsoil may be necessary to break up a hardpan, which can be created by trafficking and smearing the bottom of the tillage zone as it happens with plowing or which may develop naturally as in sodopol soils. Finally, it can be necessary to undertake soil improvements such as bringing down organic matter into the sterile subsoil or bringing up sand/clay subsoil into arable layers containing too much sand/clay in their texture.

1.3. APPROPRIATE TILLAGE ACCORDING TO SOIL CONDITIONS

An important characteristic of agricultural soil is its texture. It is usual to divide the smallest mineral particles forming the soil matrix into the three diameter classes of sand (particles between 2 mm and 0.05 mm), silt (particles between 0.05 mm and 0.002 mm) and clay (particles smaller than 0.002 mm) [2]. Gravel and cobbles (over 2 mm) appear in agricultural soils but are usually unwanted because they make tillage hazardous and keep little organic matter. Sand-sized and larger particles can be fractionated by sieving. Silt or clay particles must be estimated by hydrometer or pipette analysis. Soils are classified into several types, according to the distribution of the three particle size classes.

1.4. SOCIO-ECONOMICAL ASPECTS OF TILLAGE

Research carried out in the United States showed that, as the amount of tillage decreases (from conventional tillage to reduced tillage or no-till), the size and the number of machines decreases and costs for machinery and labor decrease, too [3]. Major costs are affected by machinery and herbicides. For corn production, the results are summarized below:

Ridge-till and no-till are the most profitable systems in different soil types.

In all cases mulch-till systems (fall chisel, disk or field cultivator) are more profitable than fall plow but not as good as ridge-till and no-till.

In poorly drained soil, ridge-till is more profitable than no-till. Slopes higher than 4% favour no-till systems.

Time requirements can be reduced by 65% and 43% when replacing conventional tillage with zero tillage and reduced tillage, respectively. At the same time, energy requirements can be reduced from more than 90 kWh/ha for conventional tillage to about 60 and 10 kW¢ h/ha, respectively, for reduced and zero tillage system. The adoption of soil conservation tillage systems suffers from many constraints, particularly in developing areas:

Lack of financial means (difficult procedures to obtain credits and subsidies, high interest rates).

Climatic conditions impose more risks with the new tillage systems.

Low technical level of farmers due to lack of research and extension.

In developed countries, energy and labor saving and the protection of soil and water from pollution and degradation are the major aspects connected with tillage. The search for adapted systems assumes that the user’s technical level and the farmer’s financial funds are taken into account. A simulation based on data of an investigation carried out in Morocco shows that the cost of direct seeding is less than for other tillage systems if the annual planted surface is larger than 60 ha. There is an urgent need to introduce sustainable agriculture in fragile ecosystems, particularly in the developing countries where low-input farming increases the environmental degradation and perpetuates low yields and low revenue.

1.5. HISTORY OF TILLAGE

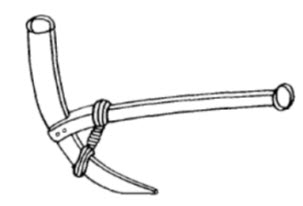

For thousands of years of recorded history, groups of human beings have been tilling the soil in order to increase the production of food. Early evidence indicates that simple light weight wooden ploughs, for instance, were employed extensively in the valleys of the Euphrates and Nile rivers by the year 3000 B.C. Animals in the form of oxen provided the traction necessary to pull the ploughs, preparing the soil for the seeding of barley, wheat and flax crops, (Encyclopedia Brittanica, 1979). The ploughs used during that period had no wheels or mould boards with which to invert the soil and prepare a true plough furrow. Nevertheless, they served to perform an initial breakup of the soil to a shallow depth and subsequently to cover the seeds of the crop. An example of an early Egyptian wooden plough is depicted in figure 1.

Fig 1. Early wooden plough, Thebes, Egypt, Cirea 3000

It was more than 200 years ago that the first iron ploughs were fabricated in Northern Honan, China. At first these were small hand-drawn tools having a flat V-shaped iron piece attached to a wooden blade and handles. During the first century B.C., water buffaloes were used to pull tillage implements. Subsequently, triple-shared ploughs, plough-and-sow instruments and harrows were developed.

Ploughs have been used also in India for thousands of years. Early implements had no wheels or mould board, being composed of wedge-shaped hard wood blocks, and pulled by bullock. The soil was broken into clods but not turned over, and this primary tillage was followed by the passage of a rectangular wooden beam, also drawn by bullock, for the breaking of clods and leveling of the seedbed.

Iron plough shares appeared on Roman ploughs about 200 years ago, as well as cutting coulters knives. Still no mould board was used to turn soil cover. These ploughs were pulled by teams of oxen, up to eight per team on a heavy soil with high strength. There were reports, but no solid evidence, that ploughs equipped with wheels appeared in Northern Italy around 100 A.D.

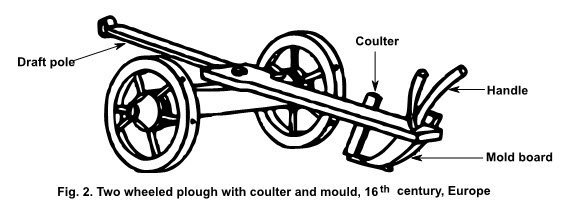

Wheels, cutting coulters and mould boards all were included on ploughs in Europe by the year 1500 A.D., as shown in figure 2. These implements could invert the soil and make true furrows and a true seed bed. High ridges of soil were left in the fields, some of which remain in evidence today. Rather than chest yokes for animals to pull tools, padded horse collars, apparently invented in China, were attached to horses. This innovation significantly improved the animal’s ability to provide draft force. Reams of two, four, eight and more horses or oxen were often used in primary soil cultivation, depending on the strength of the soil to be tilled.

Tillage implements very similar to those now in use began to appear with the introduction of the Rotherham plough in the Netherlands, England and Scotland by the early 1700’s. The principal design features of this implement remain virtually unchanged today. Also in the 18th century, Jethro Tull promoted the use of horse-drawn cultivating hoes in wide crop row spacing. The purpose of this technique was to destroy weeds competing with crops and to keep the soil in between the rows in a good crumbly and friable condition for water infiltration.

More than 100 years later, Robert Ransome patented a cast-iron plough share in 1785, and a self sharpening share in 1803. Later he introduced standard parts for tillage implements which could be replaced in the field, and a double shared plough. Around the same time, the practice of “mole” ploughing began in United Kingdom to provide subsurface drainage channels in wet fields. This technique is accomplished with deep soil cutting “leg” trailing a bullet-shaped mole at the base, which leaves continuous tube-like cavities in certain plastic soils, and greatly improves the internal drainage of wetlands.

On the American organic prairie soils, problems of satisfactory tillage induced John Deere, an Illinois blacksmith, to develop a steel plough with a one piece share and mould board in the 1830’s. Animal power for traction began to wane with the introduction of the steam powered tractor in the 1860’s, beginning with the larger farm operations. The first gasoline powered tractor appeared in the United States in 1892, and many manufacturers were producing these machines in Europe and America within a few years. The steel wheels on tractors began to be replaced by rubber tires in 1932, and by 1968 it was estimated that there were over 15 million tractors in the world.