Site pages

Current course

Participants

General

Module 1. Design and operational parameters

Module 2. Performance evaluation and maintenance a...

Module 3. Performance evaluation and maintenance a...

Module 4. Performance evaluation and maintenance a...

Module 5. Performance evaluation and maintenance a...

Module 6. Performance evaluation and maintenance a...

Module 7. Biodiesel utilization in CI engines

Lesson 26. Characteristic measurement of briquettes

The briquettes can be produced through densification process. After the preparation of briquettes, the quality of the product has to be assessed through characteristic measurement. The following methodologies are used to study the characteristics of briquettes.

Combustion properties determination

The combustion properties include percentage of volatile matter, fixed carbon, ash content and heating value. The percentage of volatile matter, fixed carbon and ash contents of four representative samples can be determined based on ASTM Standard E711-87 (2004). For percentage of volatile matter, 1g of the briquette is placed in a crucible of known weight and oven dried to constant weight after which it is heated in the furnace at temperature of 600oC for 10 minutes. The percentage of volatile matter is expressed as the percentage of loss in weight to the oven dried weight of the original sample. The percentage of ash content was measured by keeping the sample in the furnace for 3 hours in about 900°C. The ash content obtained after cooling in a dessicator is then expressed as percentage of the original sample.

Proximate Composition of fresh briquettes

|

S. No |

Briquette type |

Fixed carbon (%) |

Volatile matter (%) |

Moisture content (%) |

Ash Content (%) |

|

1 |

|

|

|

|

|

|

2 |

|

|

|

|

|

|

3 |

|

|

|

|

|

Bulk density

Bulk density of biomass briquettes is found by observing the weight of known volume of briquette.

Calorific values

Using bomb calorimeter, calorific value of briquettes can be measured.

|

Briquette types |

Powdered biomass (kCal/kg) |

Briquettes (kCal/kg) |

|

|

|

|

|

|

|

|

|

|

|

|

Characteristics of stored briquettes

Diameter study

The change in shape of briquette may be assessed by studying the diameter of the briquette before and after storage.

Measurement of strength and durability

The effectiveness of the briquettes produced during the densification process can be measured in terms of strength and durability. Procedures for measuring the compressive resistance, abrasive resistance, impact resistance and water resistance of the densified products are given below.

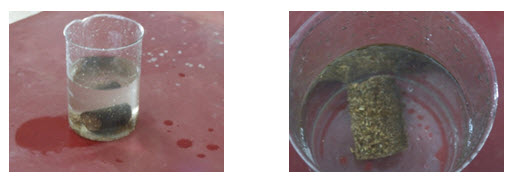

Water resistance

Short-term exposure to rain or high humidity conditions during transportation and storage could adversely affect the quality of the densified products. Each briquette is immersed in water at 27°C for one min. The swelling of briquette can be observed. Lower the swelling, better the quality.

Impact resistance

Impact resistance (or drop resistance or shattering resistance) test may simulate the forces encountered during emptying of densified products from trucks onto ground, or from chutes into bins. Briquettes may be dropped from about 1.5 m height onto a metal plate for 4-5 times. The weight retained as the percentage of the initial weight was taken as the briquette durability.

Shatter resistance

Briquettes are dropped onto a concrete surface from 1 m height for about 10 times. The percent loss indicates the shatter resistance of the briquettes. Lesser the loss better will be the resistance.

Water stability test

Water stability test

The sample piece of briquettes is dipped into the water. The time required for the briquette to become pieces may be measured. If the briquettes are stable for more than 15 min, the briquette is considered as good quality.

Thermogravimetric analysis

The thermogravimetric analysis of briquettes reveals the changes in physical and chemical properties as a function of increasing temperature or as a function of time.