Lesson 1. INTRODUCTION TO WORKSHOP PRACTICE, SAFETY, CARE AND PRECAUTION IN WORKSHOP

INTRODUCTION TO WORKSHOP PRACTICE, SAFETY, CARE AND PRECAUTION IN WORKSHOP

1.1 Introduction

Workshop practice is a very vast one and it is very difficult for anyone to claim a mastery over it. It provides the basic working knowledge of the production and properties of different materials used in the industry. It also explains the use of different tools, equipments, machinery and techniques of manufacturing, which ultimately facilitate shaping of these materials into various usable forms. In general, various mechanical workshops know by long training how to use workshop tools, machine tools and equipment. Trained and competent persons should be admitted to this type of mechanical works and permitted to operate equipment.

Processes:

1. Primary shaping processes

2. Machining processes

3. Joining processes

4. Surface finishing processes

5. Processes effecting change in properties.

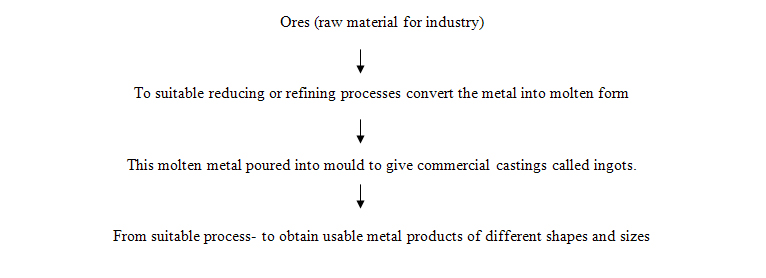

1.1.1 Primary shaping processes

Some of these finish the product to its usable form whereas others do not and it requires further working to finish the component to the desired shape and size.

Wire drawing lead to the directly usable articles, which do not need further processing before use.

Casting,forging, bending, rolling, drawing, power metal forging, etc

1.1.2 Machining processes

Large number of components need further processing after primary processes known as secondary operation to obtain desired shape and dimensional accuracy. These operations require the use of one or more machine tools, various types of cutting tools and cutters, job holding devices, marking and measuring instruments, testing devices and gauges etc.

Common machining operations are:

Turning,Threading. Drilling, Boring, Planning, Shaping, Sawing, Milling, Grinding,Slotting, etc.

1.1.3 Joining processes

These processes are used for joining metal parts and in general fabrication work. Such requirement usually occur when larger lengths of standard sections are required or several pieces are to be joined together to fabricate a desired structure.

Common processes are Welding, Soldering, Brazing, Riveting, Screwing, Pressing, etc.

1.1.4 Surface finishing processes

These processes should not be misunderstood as metal removing processes in any case as they are primarily intended to provide a good surface finish or a decorative and/or protective coating on to the metal surface, although a very negligible amount of metal removal or addition may take place. Thus, any appreciable variation in dimensions will not be effected by these processes. The common processes employed for obtaining desired surface finish are the following:

1. Buffing 2. Polishing

3. Lapping 4. Belt grinding

5. Metal spraying 6. Painting

1.1.5 Processes effecting change in properties

These processes are employed to impart certain specific properties to the metal parts so as to make them suitable for particular operations. Most physical properties like hardening, softening and grain refinement etc., call for particular heat treatment. Heat treatments not only effect the physical properties, but in most cases also make a marked change in the internal structure of the metal. So is the case with cold and hot working of metals.

1. Heat treatment 2. Cold working

3. Hot working

Workshop safety

The safety in Workshops has been written not only to provide appropriate safety procedures but also to assist trained workshop personnel with the provision of a reference document outlining the general principles of safe working practices relevant to the mechanical engineering aspects. It relates to specific are as where definite safety measures are required for workshop operations

Factories Act and Accident

Various acts relating to accidents are spelt out in workmen’s compensation Act-1923, The factories act-1948 and Fatal Accidents Act-1855. These acts describe the regulations for fencing and guarding the dangerous machinery, items and employer’s liabilities.

1.1.6 Concept of accident

It is very difficult to give a definition of the word‘Accident’. However, a generally accepted conception that an accident is a mishap, a disaster that results in some sort of injury, to men, machines or tools and equipments and in general loss to the organization.

The said injury or loss may be of minor or major nature and the accident is termed as non-reportable or reportable. For example, a small cut on the body will be reportable accident in a training workshop. It can be treated by first aid and does not involve any appreciable loss of time, and will not be considered a reportable accident in a production unit.

1.1.7 Causes of accidents

The 98% accidents could be easily avoided provided due precautions are taken well in time. A very familiar slogan goes on to say that accidents do not just happen but are caused due to the failure of one element or the other, and the most unfortunate factor is that the human element is the most pronounced of all which fail.

The common causes which lead to accidents are the following:

1. Unsafe working position.

2. Improper or defective tools or their improper use.

3. Improper acts- which result in violation of safety rules and non-observance of safety precautions.

1.1.8 Common sources of accidents

The large number of machines in use and an even larger number of parts. This can be regarded as sources of danger and require guarding for protection against accidents.

Some common sources of accident are listed below :

Projecting nips between sets of revolving parts, viz., gears, rolls and friction wheels, etc.

1. Projecting fasteners on revolving parts.

2. Revolving cutting tools, circular saw blades.

3. Revolving drums, crushers, spiked cylinder and armed mixers, etc.

4. Revolving shafts, spindles, bars and tools like drills,reamers, boring bars and chucks, etc.

5. Projecting sharp edges or nips of belt and chain drives viz., belt, pulleys, chains, sprockets and belt fasteners.

6. Reciprocating tools and dies of power presses, drop hammers, and revolving presses, etc.

7. Grinding wheels and stones.

8. Reciprocating knives and saw blades such as cutting and trimming machines and power hack-saws, etc.

9. Revolving drums and cylinders without casing, such as concrete and other mixers.

10. Intermittent feed mechanisms.

11. Projecting nips between various links and mechanisms, like cranks connecting rods, piston rods, rotating wheels and discs, etc.

1.2. Common Methods of Protection

The common methods of protection against accidents are the following:

1. Safety by position.

2. Safety by construction.

3. Safety by using interlock guards.

4. Safety by using fixed guards.

5. Safety by using automatic guards.

6. Safety by using distance guards.

1.2.1 Safety by construction

When a new machine is designed, it should be ensured that all its dangerous parts are either enclosed in suitable housings or provided with suitable safety guards. For example, the belt drive and motor in a lathe or milling machine are enclosed, the back gears in a lathe are either enclosed or provided with cast iron guards or covers. Lubricating points are provided on the outer surfaces so that the interior parts are not required to be opened every time.

1.2.2 Safety by position

The machine design is in such a way that the dangerous parts are located such that they are always beyond the reach of the operator. The dangerous parts of all the machines should invariably be guarded and undertaking should be made to make them enclosed in the body or housing of the machines.

1.2.3 Safety by using interlock guards

It is a very efficient and sound method of guarding in that the guard cannot be removed and dangerous parts exposed until and unless the machine is totally stopped. Similarly, the machine cannot be started to work unless the guard returns in position and protects the dangerous parts.

An interlocking guard may be mechanical,electrical or some sort of a combination of these. It is essential that it should:

1. Prevent the starting and operation of the machine in case the interlocking device fails.

2. Always acquire its position to guard the dangerous part before the machine can be started.

3. Remain closed in position until the dangerous part is completely at rest.

1.2.4 Safety by using fixed guards

These guards either for man integral part of the machine or are tightly secured to them. They should be made to have rigid construction and should be so placed that any access to the dangerous parts of the machine is totally prevented in the running condition of the machines.

Steel sheets can be advantageously used and they facilitate an easy fabrication of guards and are lighter in weight.

In some cases the fixed guards are made adjustable in order to accommodate different kinds of works or sets of tools. In some cases the fixed guards are provided at a distance from the danger point.

1.2.5 Safety by using distance guards

The principle of a distance guards is that a fencing, enough high, is made of bars,at a suitable distance from the machine such that even if the operative, by chance, extends his hands over it, his fingers, clothes or any part of the body does not reach within the area of dangerous parts. An additional measure of safety, some sort of tripping device is also usually incorporated to stop the machine quickly in case of an accident.

1.2.6 Safety by using automatic guards

The principle of an automatic guard is that its operation is actuated by some moving part of the machine.

It may linked that the part will automatically bring the guard in protecting position before the operation of the machine starts. The design of the guard is such that it automatically forces the operative away from the dangerous area of work before the operation starts and does not permit his access to the area again until and unless the machine stops. It may be noted that due to enough time being required for their operation, this type of guards are not suitable for quick-acting and fast-running machines. Their use is largely favoured for heavy and slow acting machines like heavy power presses.