Site pages

Current course

Participants

General

Topic 1

Topic 2

Topic 3

Topic 4

Topic 5

Topic 6

Topic 7

Topic 8

Topic 9

Topic 10

Topic 11

Topic 12

Topic 13

Topic 14

Topic 15

Lesson 8. Study of mould board plough: accessories, adjustments, operation and material of construction Mould Board Ploughs

Equipment used by the farmer to break and loosen the soil for a depth of 6 to 36 inches is called primary tillage equipment.

Why plowing is done?

1) To obtain a deep seed bed for good structure

2) To add more humus and fertility to the soil by covering, vegetation and minerals.

3) To destroy weeds.

4) To leave the soil in a condition to breath or allow the air to circulate freely.

5) To facilitate the introduction of seed in the soil with better contact.

6) To destroy insects and their eggs along with their breeding places.

7) To leave the surface in the condition to prevent erosion by wind

8) To get greater root protection.

When to plow?

1) Early plowing during rainy season reduces weeds. When buried in soil work it becomes manure and is of great importance.

2) In our country there are high winds which bring with them considerable amount of dust with particles of grass, leaves, crop residue like bhusa and all sort of vegetation which settle on ploughed, rough, cloddy surface of field which otherwise get blown off.

3) In a long period of dry and hot weather a good amount of nitrogen is built up in the air and this is caught by first rainfall and brought to the soil. In case the field is ploughed this rain water with nitrogen gets absorbed in loose soil hence works as fertilizer.

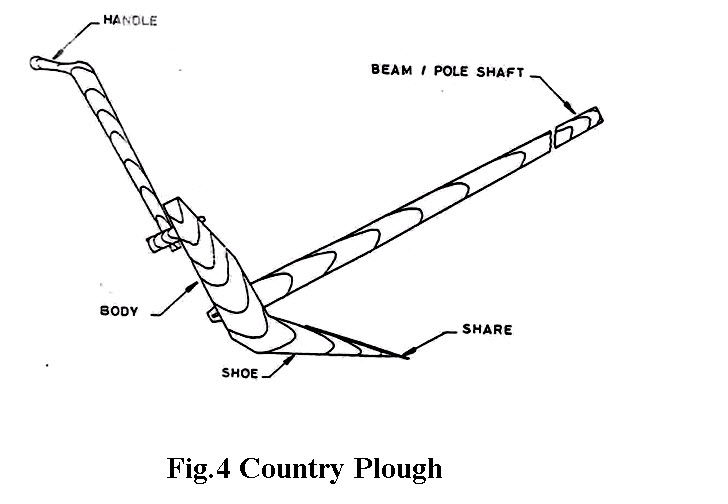

In olden days “Desi” wooden plows were popular throughout the world. In 14th century after introduction of steel, steel plows were popular throughout the world.

Mould board plows are:

One of the oldest of all agricultural implements

It is considered to be the most important tillage implement

It consumes more traction energy than any other operation

It cuts loose the furrow slice, inverts the furrow slice more or less in pulverized form

It is used for covering grass into soil immediately after rains

But its design largely depends upon cut and try methods.

Types of mould board plows:

1) Trailed: It is also known as pull type and it is complete unit in itself supported on two wheels.

The complete unit is hitched by the drawbar of the tractor.

It is available in 1-8 bottoms depending upon the capacity of the tractor.

Single bottom has one bottom. Two – Eight bottoms are called as gang mould board.

Sizes available are 36, 41 and 46 cm.

These are not easily maneuverable.

2) Semi-Mounted: These are more compact and more maneuverable than pull type.

Sizes and number of bottoms are same as that of pull type.

These are less expensive.

These put more vertical load on tractor rear wheels (there by improving tractive ability).

3) Mounted: These are called as direct mounted, tractor mounted or tractor carried plows.

These plows use tractor lift linkages which are controlled hydraulically.

It is available in 2-5 bottoms depending upon the capacity of tractor.

Sizes available are 30, 36 and 41 cm.

Increased size of mounted type plows cause tractor instability during transport.

Classification of mould board plows:

1) One way plow: It turns soil to the right hand side.

One way plow require laying out a field in lands, starting with back furrows and ending with dead furrows.

2) Two way plow: It turns soil to both right and left side.

Two sets of bottoms are mounted on a common frame that is rotated about a longitudinal axis to change from one set to other.

Mechanical or hydraulic cylinders are used for rotation

Gage wheels and rear wheels are automatically repositioned as the plow bottom frame rolls over, unless each set of bottoms has its own wheel (which is usually the case of mounted plows).

Two way plows eliminate the back furrow and dead furrow leaving the field more level for irrigation or drainage.

Two way plows are advantageous for terraced fields or contour ploughing and for small irregular shape fields.

Animal drawn two way plow is also called as turn- wrest plow.

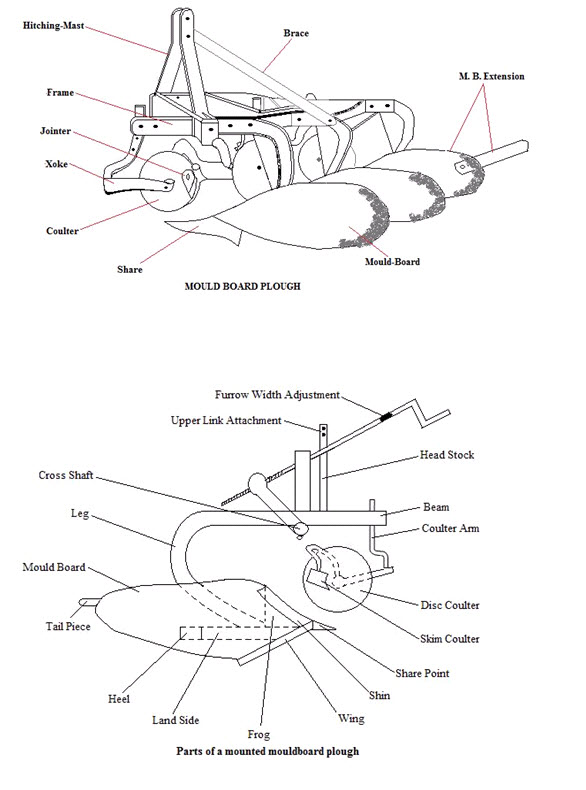

Parts of Plow:

1) Plow Bottom

2) Plow Frame

3) Attachments (Coulters & Jointers)

4) Wheels

5) Lifting Mechanism

6) Plow Hitch

7) Depth Adjusting Mechanism

1) Plow Bottom: It is the actual part of the plow.

It is three sided wedge.

There are three main parts i.e. mould board, landslide and share which are rigidly fastened to the frog.

Its main function is to cut the furrow slice, shatter the soil and invert the furrow slice to cover trash.

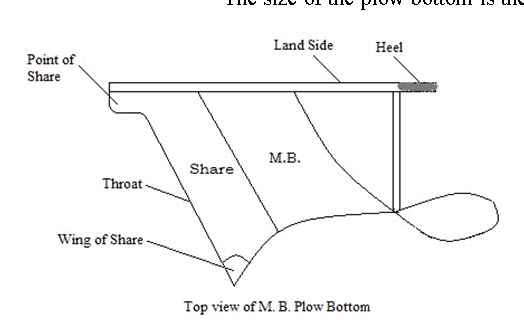

The size of the plow bottom is the width of furrow it is designed to cut.

a) Share: It is the part of plow bottom which actually penetrates into the soil and makes a horizontal cut below the surface.

b) Mould Board: It is the curved part which lifts and turns the slice.

c) Landslide: It is the flat plate which bears against and transmits the rear side lateral thrust of plow bottom to the furrow wall.

d) Frog: It is the base of the plow bottom to which other parts are attached.

e) Tail Piece: It is the extension of mould board which helps in turning the furrow slice.

Types of Mould Board:

Different soil conditions require plow bottoms of different shapes. The moisture in the soil and texture of soil determines whether it should pulverize thoroughly or merely turned over to be pulverized later on.

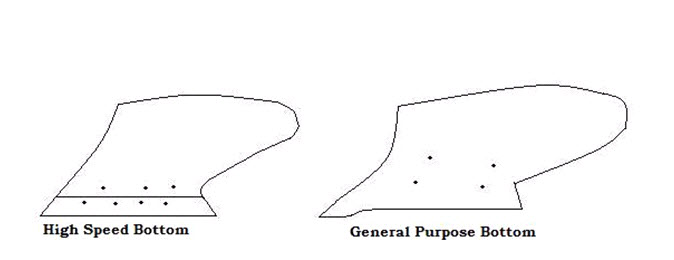

a) General Purpose and High Speed:

These are mostly used and suitable for wide range of conditions. It mostly meets the general demand of seedbed preparation.

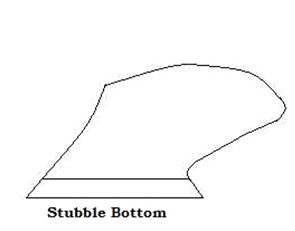

b) Stubble Bottom:

It is generally used for old ground where good pulverization is required. It has relatively short and broad mould board which is curved rather abruptly near the top, resulting in a greater degree of pulverization than with other types.

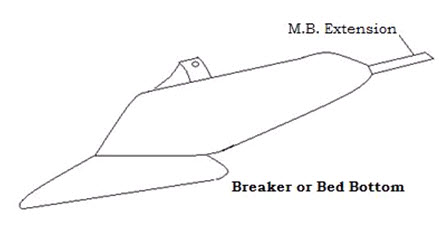

c) Sod or Breaker Bottom:

c) Sod or Breaker Bottom:

It is used in tough soil where furrow slices are completely turned over so that grass doesn’t grow. It has a long and low mould board with a gradual twist (spiral) that completely inverts the furrow slice with a minimum of breakup, thus covering vegetative matter thoroughly.

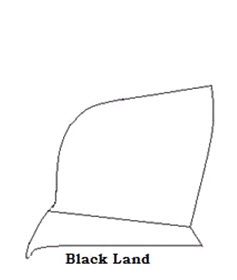

d) Black land Bottom:

It is used for plowing gumbo or buckshot soil where scouring (cleaning) is a problem. It has relatively small mould board area, and its shape tends to promote scouring soils.

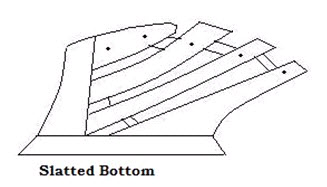

e) Slat Bottom:

It is the less common type. It is highly favorable in light and sticky soils where general purpose plow doesn’t scour. The slates fitted give high pressure between soil and mould board scours better.

Material Used for Mould Board:

General Purpose High Carbon Steel

Stubble Bottom -----do-----

Sod or Breaker -----do-----

Slat Bottom -----do-----

High Speed -----do-----

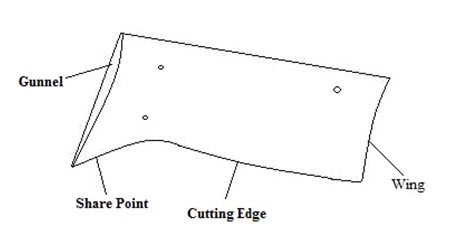

Parts of Share:

a) Share Point:

It is the forward end of the cutting edge, which actually penetrates in the soil.

b) Cutting Edge:

Front edge of the share, which makes horizontal cut in the soil.

c) Wing of Share:

Outer end of cutting edge of share. It supports the plow bottom.

d) Gunnels:

It is vertical face of share, which slides along the furrow wall. It takes side thrust of soil and supports the plow bottom against the furrow wall.

e) Cleavage Edge:

It is the edge of the share which forms joint between mould board and share on frog.

f) Wing Bearing:

Level portion of wing of the share providing a bearing for outer corners of plow bottom.

g) Throat:

Principle parts of the share i.e. share point, wing and cutting edge is also called as throat. Point is the first part to penetrate in the soil, the wing is the outside corner of the cutting edge. The cutting edge extending from the point to the wing is curved and forms the throat of the share.

Types of Shares:

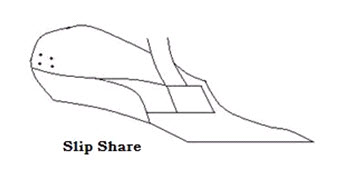

a) Slip Share:

One piece share with curved cutting edge, having no additional part.

Common type of share generally used by the farmers, as it is simple in design.

Disadvantage is that entire share has to be replaced if it is worn out due to constant use.

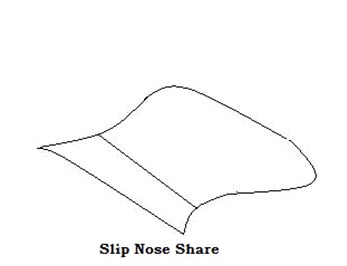

b) Slip-nose Share:

It is a share in which point of share is provided by a small detachable piece.

Advantage is that share point can be replaced as and when required. So it is economical.

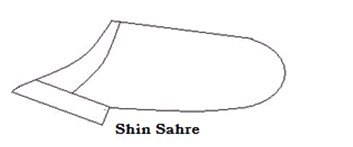

c) Shin Share:

It has a shin as an additional part.

It is similar to slip share with a difference that an extension is provided by side of the mould board.

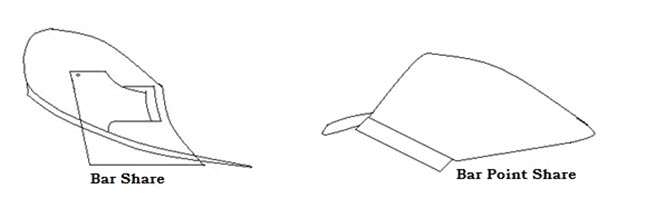

d) Bar Point Share:

It is the share in which point of share is provided by an adjustable and replaceable bar.

This bar serves the purpose of point of share and landslide of the plow.

Materials Used for Share:

Slip Share HCS, soft center steel, cast iron

Slip-nose Share Cast iron

Shin Share HCS

Bar Point Share HCS

1) Cast Iron Share:

These are made for cheap type of plow.

Require careful handling, as these are brittle and can break easily with sharp blow. If it is broken it has to be replaced. But if it is worn it can be sharpened with the help of grinding stone.

2) Chilled Cast Iron Shares:

These shares have comparatively longer life as these do not rust and do not wear quickly.

These are recommended for sandy and strong soils.

3) Soft Center Steel Shares:

These are used in the soils where soil doesn’t stick to the surface of share or mould board.

These have very hard surface and long life but are costly.

4) Solid Steel Share:

These are used where soil is not abrasive.

These are quite sturdy and can withstand shocks.

These are made out of high carbon steel by forging process.

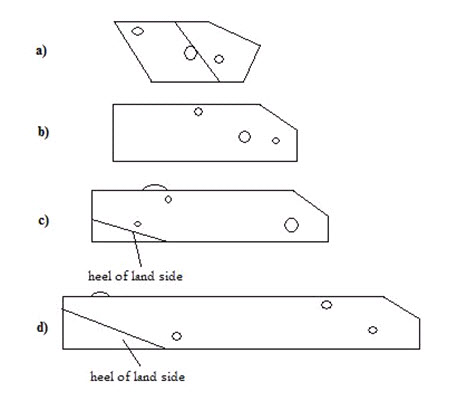

Types of Landslide:

a) This landslide is about 23 cm long and is used for plows where landslide pressure is not a factor.

b) This landslide is 28 cm long and is used for normal plowing conditions.

c) This landslide is 36 cm long and has landslide heel used for abrasive soils.

d) This landslide is 50 cm long and has a landslide heel. It is used in plows which don’t have rear furrow wheel, it gives support to plow bottom.

Material used for Landslide:

Soft center steel/ MS/ cast iron

Material used for Frog:

MS/ cast iron