Site pages

Current course

Participants

General

Topic 1

Topic 2

Topic 3

Topic 4

Topic 5

Topic 6

Topic 7

Topic 8

Topic 9

Topic 10

Topic 11

Topic 12

Topic 13

Topic 14

Topic 15

Lesson 10. Disc plough: standard and vertical ; principle of operation, adjustments and accessories

Disc Plough:

As the name implies it is in the form of a disc.

Disc plows are designed to reduce friction by making a rolling plow bottom instead of sliding plow bottom.

It cut, inverts and in some cases breaks furrow slices by means of separately mounted large steel discs to one side.

Advantages over Mould Board Plough:

Disc plow can be forced to penetrate into soil, which is too hard and dry for working with a mould board plow.

It works well in sticky soil in which a mould board plow doesn’t scour.

It is more useful for deep plowing.

It can be used in stony and stumpy soil without much danger of breakage.

A disc plow works well even after a considerable part of disc is worn off in abrasive soil.

It works in loose soil without much clogging.

When scrapers are fitted it also inverts the soil.

If disc plow is used without scraper it has more mixing action rather than inversion.

The maintenance cost is low, as there are no shares to replace or sharpen as compared to mould board plows.

Disadvantages of Disc Plow:

Disc plow cannot be used at high speed since for cutting action at slow speed is necessary.

It is not suitable for covering surface trash and weeds as effectively as mould board plow.

It leaves field rough and cloddy than mould board plow.

It is heavier than mould board plow for equal capacities as penetration depends on weight rather than suction.

Types of Disc Plow:

Disc plows are divided into two main categories

1) Bullock drawn

a) Sulky type

b) Gang type: attached to universal frame which is mounted on two wheels.

2) Tractor drawn

a) Direct mounted

b) Semi-mounted

c) Trailed

3) According to mounting of Discs

a) Standard disc plow

b) Vertical disc plow or harrow plow or wheat land plow

c) Cylinder plow or disc tiller or tiller disc plow

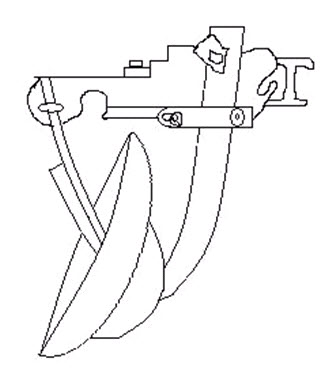

Standard Disc Plow:

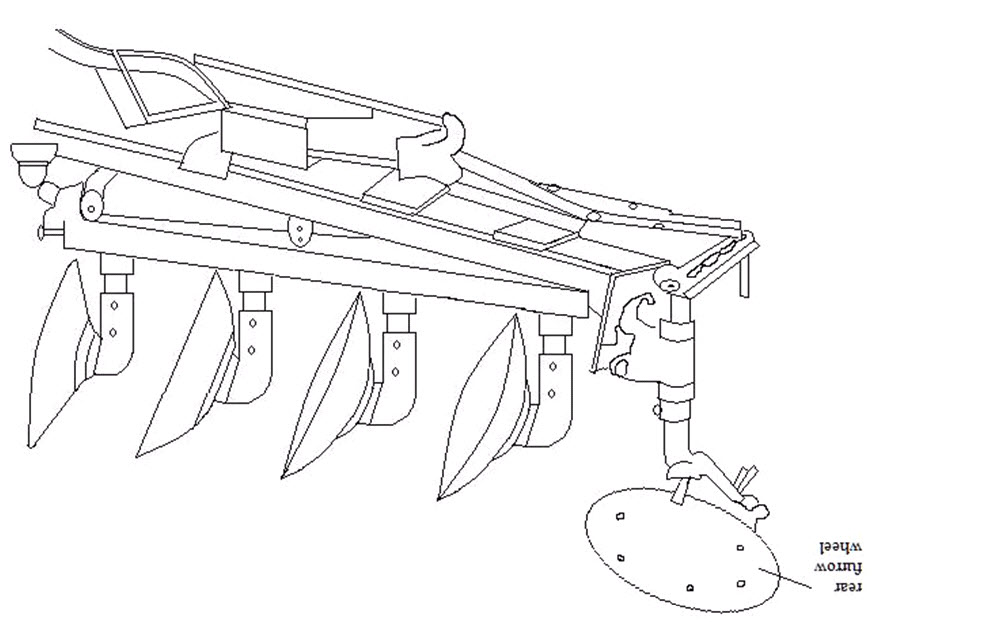

Three bottom mounted type standard disc plow, six bottom trail type standard disc plow, four bottom mounted type reversible standard disc plow.

A series of individually mounted inclined disc blades on a frame supported by wheel.

Usually have 3 to 6 disc blades spaced to cut 18 to 30 cm per disc.

Discs are tilted backward at an angle of 15 to 25 degree from vertical and disc angle of 42 to 45 degree from direction of travel.

Disc diameter ranges from 61 to 71 cm.

Scrapers are used for assisting discs in covering trash and prevent soil build up on disc in sticky soil conditions.

Reversible disc plow (usually mounted or semi-mounted) have an arrangement to reverse the disc angle at each end of field to permit one way plowing.

Used in hard and dry soil. Disc tools are forced into ground by effect of gravity upon its mass rather than suction.

Total mass of disc plow varies from 200 to 600 kg.

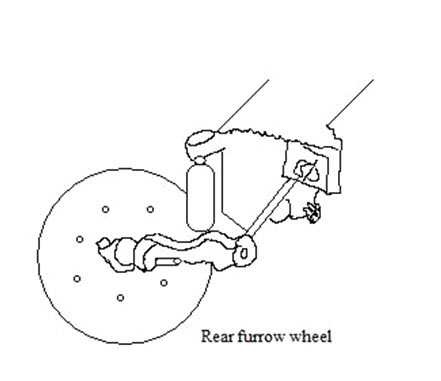

In mounted type, wheels of tractor take side thrust. Sometimes a rear wheel is fitted to take side thrust of plow to some extent.

In trailed type, furrow wheel bears the side thrust.

Disc is made of heat treated steel of 5 mm to 10 mm thickness.

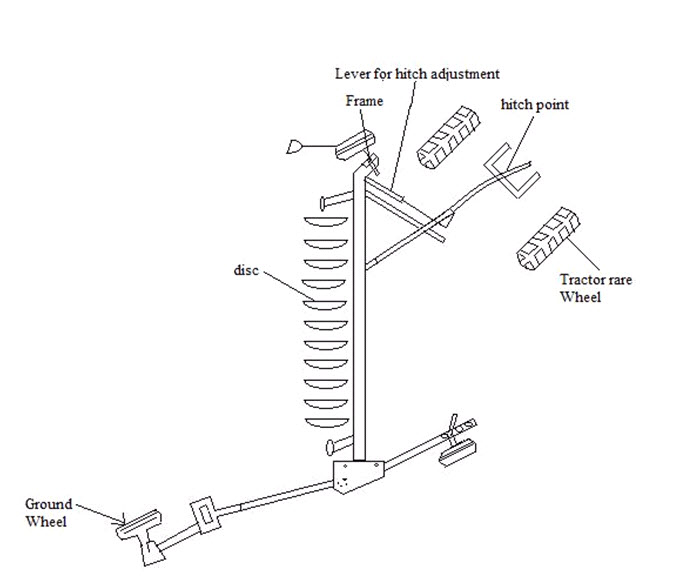

Vertical Disc Plow:

Also called as one-way disc plow, harrow plow and wheat land plow.

Similar to pull type and standard disc plow but discs are uniformly spaced along a common axle or gang bolt and clamped together through spacer spools so the entire gang rotates as a unit (as in disc harrow).

It is about halfway between the standard disc plow and disc harrow in its soil working action.

Generally used in plain areas and where shallow plowing and mixing of stubble with soil is required. Diameter of discs varies from 51 cm to 61 cm and spacing from 20 to 25 cm apart along the gang bolt. Width of cut per disc depends upon the angle between gang axis and direction of travel. Disc angle ranges from 35 to 60 degree and most common angle is 40 to 45 degrees.

Width of cut obtained from various sizes of vertical disc plow ranges from 2 to 6 m. weight of plow ranges from 50 to 100 kg.

Comparison between Standard Disc Plow and Vertical Disc Plow

|

S. No. |

Comparison |

Standard Disc Plough |

Vertical Disc Plough |

|

1. |

Mounting of disc |

Individual axis |

Common axis |

|

2. |

Number of discs |

1-6 |

5-24 |

|

3. |

Sizes of discs |

60-75 cm |

40-60 cm |

|

4. |

Spacing |

18-30 cm |

18-22 cm |

|

5. |

Concavity |

More |

Less |

|

6. |

Depth of cut |

30-40 cm |

8-10 cm |

|

7. |

Angle to direction of travel |

42-45 degree |

35-60 degree |

|

8. |

Tilt angle |

15-25 degree |

0 degree |

|

9. |

Weight/disc |

200-600 kg |

50-100 kg |

|

10. |

Draft requirement |

High |

Low |

In standard disc plow provisions are made for adjustments of disc angle and tilt angle.

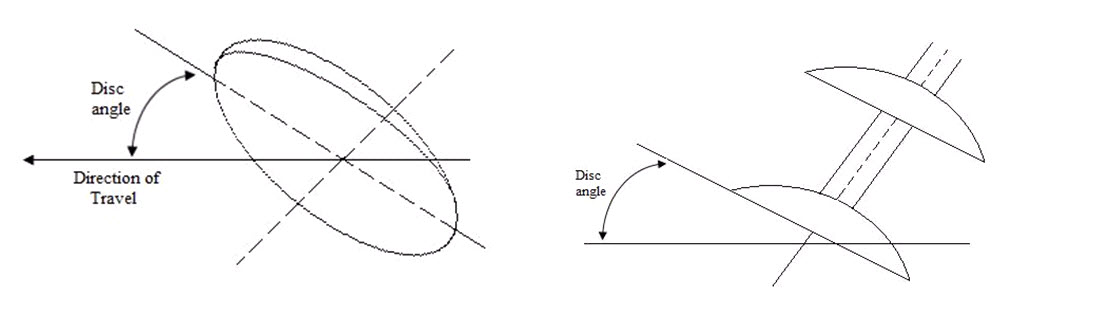

DISC ANGLE: The angle at which the plane of cutting edge of disc is inclined to direction of travel is called Disc Angle. It varies from 42 to 45 degree.

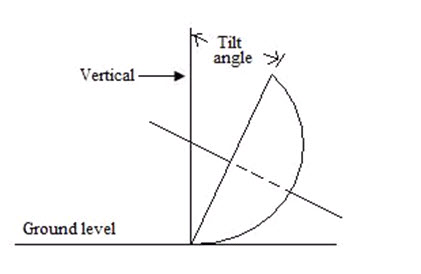

TILTANGLE: It is the angle at which the plane of cutting edge of disc is inclined to vertical line. Tilt angle varies from 15 to 25 degree.

Adjustment of tilt angle:

Shifting standard on the frame

By adjusting blocks

Changing grooves in bearing brackets

Parts of Disc Plough:

(1) Disc blade: Disc type blades are mounted for cutting of soil. Number of blades and diameter determine plough capacity. Concavity affects disc angle and soil turning. Shallow concavity depends on diameter of discs. Depth of cut depends on diameter of discs. About 1/3rd of blade diameter is the limit for depth. Width of cut depends on diameter of blade. Width of cut is normally 0.4 times of diameter of disc blade.

(2) Standard: Connects disc bearing and plough frame. Sometimes beam is bent for disc attachment for reducing the cost.

(3) Plough Frame: Standards are attached to the plough frame. It has provision for disc angle adjustment, adding or removing standard and discs.

(4) Rear Furrow Wheel: To stabilize the plough and take side thrust, rear furrow wheel is fixed at end.

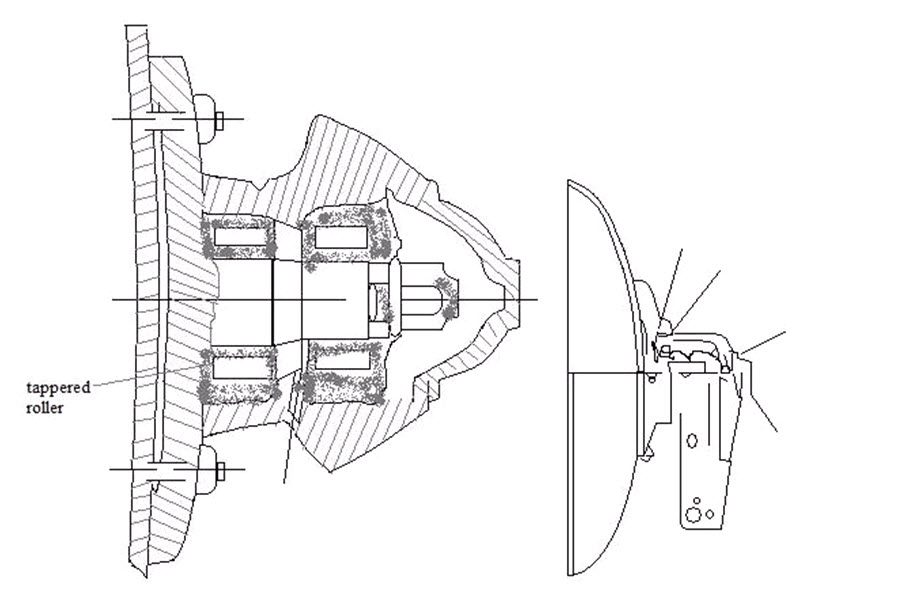

(5) Bearings: Disc blades are at an angle to the direction of travel so both radial and thrust forces are present. Radial forces push against an axle at right angle while thrust forces push along the axis. That is why taper roller bearings are used.

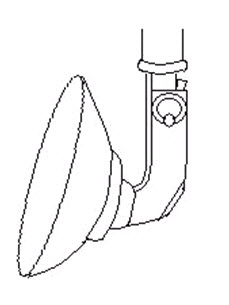

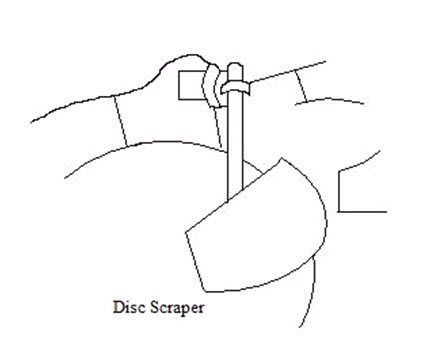

SCRAPER: Device to remove soil that tends to stick to working surface of a disc, for great pulverization to furrow slice, invert the furrow slice and cover the trash better.

Types of scrapers:

1) Disc scraper used in non-scouring soils

2) Mould board scraper used to turn over soil and trash

3) Hoe scraper used in sticky soils.

CONCAVITY: It is the depth measured at the center of disc by placing its concave side on flat surface.

DRAFT OF DISC PLOW: The disc plows is lighter in draft than the mould board plow, turning same volume of soil in similar conditions. In very hard soil some extra weight is added to the wheel which increases draft. The bearing and scrapers of disc plow also affect the draft.

- Different adjustments on disc plow affect depth of cut, width of cut and pulverization of soil as;

i) Penetration is improved by increasing disc angle.

ii) Penetration is improved by decreasing tilt angle on standard disc plow.

iii) Penetration is improved by adding additional weight on plow.

Depth of penetration ranges 3” - 15”. For better penetration discs should be sharpened.

- Width of Cut:

-It is adjusted by adjusting angle between land wheel axle and frame.

-Improved by increasing disc angle and decreasing tilt angle.

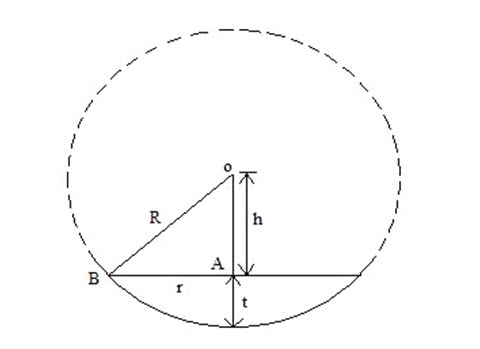

To Compute Radius of Curvature of Discs:

R – Radius of Curvature

r – Radius of disc

t - Depth or concavity

OAB

R2 = h2+r2

Also, h = R-t

h2 = (R-t)2

h2 = R2 - 2Rt + t2

R2 = R2 - 2Rt + t2 + r2

2Rt = t2 + r2

R = t2 + r2

2t 2t

R = t + (D/2)2

2 2t

R = t + D2

2 8t

Trouble Shooting

|

Defect |

Reasons |

Remedy |

|||

|

1. |

Low Penetration |

1. |

Blunt disc |

1 |

Sharpen the edge |

|

2. |

Plow too light |

2. |

Put additional load |

||

|

3. |

More tilt angle |

3 |

Set tilt angle |

||

|

|

|

|

|

|

|

|

2 |

Heavy draft |

1. |

Blunt disc |

1. |

Sharpen the edge |

|

|

|

2. |

Furrow too wide |

2. |

Reduce tilt angle |

|

|

|

|

|

|

|

|

3. |

Excessive Side Draft |

1. |

Improper hitching |

1. |

Hitch properly |

|

|

|

|

|

|

|

|

4. |

Less Scouring |

1. |

Defective Scraper |

1. |

Adjust the Scraper |

|

|

|

|

|

|

|

|

5. |

Uneven Furrows |

1. |

Disc angle not uniform |

1. |

Set disc angle |

|

|

|

2. |

Loose bearings |

2. |

Set bearings |

|

|

|

3. |

Hitching defective |

3. |

Set hitching |