Site pages

Current course

Participants

General

Topic 1

Topic 2

Topic 3

Topic 4

Topic 5

Topic 6

Topic 7

Topic 8

Topic 9

Topic 10

Topic 11

Topic 12

Topic 13

Topic 14

Topic 15

Lesson 22. Sowing methods and practices, functions and constructional features of a seeding/ planting machine

SEEDING AND PLANTING MECHANISMS

Crop Planting:

Crop planting operations may involve placing of seeds or tubers in the soil at

Pre-determined depth

Random scattering or dropping of seeds on field surface (broadcasting)

Setting plants in the soil.

So, seeding or sowing is an art of placing seeds in the soil to have good germination in the field. A perfect seeding gives:

a) Correct amount of seed per unit area

b) Correct depth at which seed is placed in the soil

c) Correct spacing between row to row and plant to plant.

Methods of Sowing:

a) Broadcasting: It is the process of random scattering of seeds on the surface of seed bed. It can be done manually or mechanically. When broadcasting is manual uniformity of seed depends upon skill of man. It requires high seed rate. While in mechanical broadcasting seed rate may be controlled. Machine used is called mechanical broadcaster.

b) Dibbling: Process of placing seeds in holes made in seed bed and covering them. In this method seeds are placed in holes made at definite depth at fixed spacing. Equipment used is called dibbler. It is a conical instrument used to make proper holes in the fields. Small hand dibblers are made with several conical projections made in a frame. Time consuming process, specially used for vegetable sowing.

c) Drilling: Process of dropping the seeds in furrows in a continuous flow and covering them with soil. Seed metering may be done either manually or mechanically. The number of rows planted may be one or more. This method is very helpful in achieving proper depth, proper spacing and proper amount of seed to be sown in the field.

Drilling can be done by:

Sowing behind the plow

Bullock drawn seed drill

Tractor drawn seed drill

d) Seed dropping behind the plow: It is very common method used in villages. It is used for seeds like maize, gram, peas, wheat and barley. A man drops seeds in the furrows behind the plow with a device called malobansa. It consists of a bamboo tube provided with a funnel shaped mouth. A man drops seeds through the funnel and other man handles the plow and bullocks. This is slow and laborious method.

e) Hill Dropping: In this method seeds are dropped at fixed spacing and not in continuous stream. Spacing between plant to plant in a row is constant. In case of drills seeds are dropped in a continuous stream and spacing between plant to plant in a row is not constant.

f) Check Row Planting: In this row to row and plant to plant distance is uniform. Seeds are placed precisely along straight parallel furrows. The rows are always in two perpendicular directions. Machine used is called check-row planter.

g) Transplanting: It consists of preparing seedlings in nursery and then planting these seedlings in the prepared field. Commonly used for paddy, vegetables and flowers. It is time consuming operation and equipment used is called transplanter.

h) Row-Crop Planting: If rows/planting beds are far enough apart to permit the operation of machinery between them for inter tilling/other cultural operations, it is called row crop planting. It is done by any method discussed other than broadcasting. In row crop planting system planting may be done on:

Flat surface of seed bed

In furrows or on beds

i) Furrow Planting: (Or lister planting) is widely practiced under semi-arid conditions for row crops as corn, cotton and grain sorghum. This system places the seed down into the moist soil and protects young plants from wind and blowing soil.

Furrow planting provides a flat plateau perhaps 7.5 cm high and 25 cm wide in the bottom of furrow.For furrow planting small furrows beside the plateau keep water from standing on the row or washing soil into the row if a heavy rain occurs.

j) Flat Planting: It is practiced under natural moisture conditions.

k) Bed Planting: It is practiced in high rainfall areas to improve surface drainage.

Bed planting is common for certain types of row crops in irrigated areas with close-spaced row crops such as sugar beet, lettuce and certain other vegetable crops.

Two or more rows are planted close together on a single bed, thereby leaving more width in the spaces between beds for the operation of equipment.

Beds can be on 102 or 107 cm centers with two rows 30 to 40 cm apart on each bed.

l) Combination Bed-Shaping and Planting Units: These are used for vegetables like sugar-beet and other similar crops in irrigated areas.

A unit simultaneously pulverizes the seed bed strip with rotary tiller, incorporates pesticides, form the bed to a firm, flat top shape, applies fertilizers and plants the seeds. Sled runners between beds guide and support the implement while it is in operation, thus minimizing height variations.

It results in precise operation in which the seeds and chemicals are accurately placed at specific locations with respect to each other and w.r.t. top and sides of each bed.

If relationships have been properly selected, results should be better and more uniform than from separate operations.

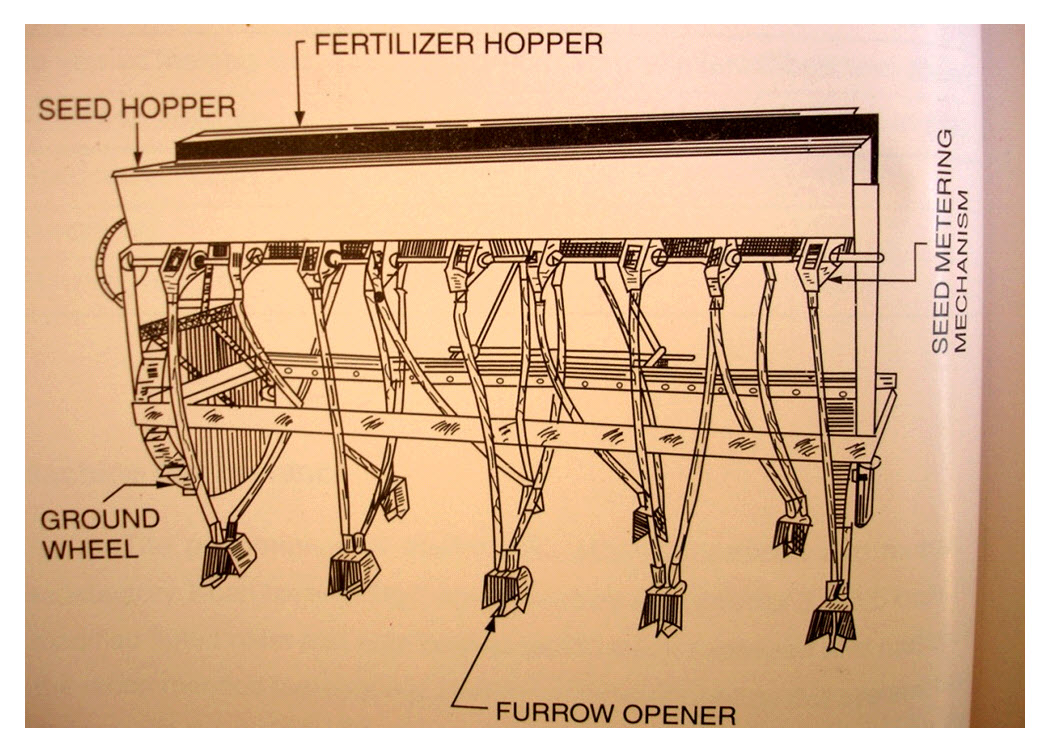

Seed Drill:

Seed drill is a machine for placing seeds in a continuous flow in the furrows at uniform rate and at controlled depth with or without the arrangement of covering them with soil.

Seed Drill

Functions of Seed Drill

1) To carry the seeds

2) To open the furrow to an uniform depth

3) To meter the seeds

4) To place the seed in furrows in an acceptable pattern

5) To cover the seeds and compact the soil around the seed.

Seed-cum-Fertilizer Drill

Seed drills fitted with fertilizer dropping attachment distribute fertilizer uniformly on ground is called seed-cum-fertilizer drill.

Seed drills may be classified as:

Bullock Drawn and Tractor drawn

Components of Seed Drill:

A seed drill with mechanical seed metering device mainly consists of:

1) Frame: The frame is usually made of angle iron with suitable braces and brackets. The frame is strong enough to withstand all types of loads in working conditions.

2) Seed Box: It is made of mild steel or galvanized iron with suitable cover. A small agitator is sometimes provided to prevent clogging of seeds.

3) Covering Devices: It is a device to refill a furrow after seed has been placed in it. Covering of seeds are usually done by patta, chains, and drags, packers, rollers or press wheels designed in various sizes and shapes.

4) Transport Wheel: There are two wheels fitted on main axle. Some drills have a pneumatic wheel. The wheels have suitable attachments to transmit power to operate seed dropping mechanisms.

Seed Metering Mechanisms:

The mechanism of seed drill which delivers seeds from hoper at selected rates is called seed metering mechanism. These are of various types:

a) Fluted Feed Type: It is a seed metering device with an adjustable fluted roller to collect and deliver the seeds into the seed tube. It consists of a fluted wheel, feed roller, feed cut-off and adjustable gate for different size of grains. The feed roller and feed cut-off devices are mounted on a shaft, running through feed cups. The roller carries groves throughout its periphery. It rotates with the axle over which it is mounted and throws the grains out on the adjustable gate from where it falls into seed tube. Fluted rollers which are mounted at bottom of seed box, receive seeds into longitudinal groves and pass on to the seed tube through the holes provided for this purpose. By shifting the fluted wheel sideways, length of the groves exposed to seed can be increased or decreased and thus the amount of seed is controlled. Thus number of selections is available between closed position and full exposure of fluted wheel. This method is more positive in its metering action than internal double run type.

Fluted roller type

b) Internal Double Run Type: It is a seed metering device in which feed wheel is provided with fine and coarse ribbed flanges. It consists of discs, mounted on a

spindle and housed in a casing fitted below the seed box. It has a double faced wheel, one face has a larger opening for longer seeds and other face has smaller opening for smaller seeds. A gate is provided in the bottom of the box to cover the opening not in use. The rate of seeding is varied by adjusting speed of the spindle which carries the discs.

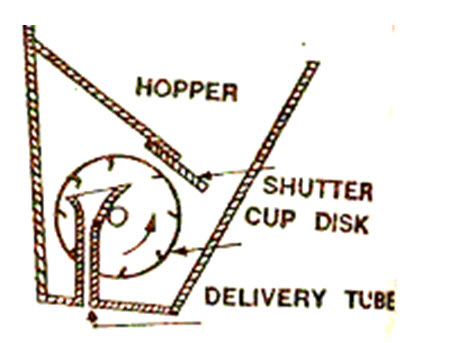

c) Cup Feed Mechanism: It is a mechanism consisting of cups or spoons on the periphery of a vertical rotating disc which picks up the seeds from the hopper and delivers them into seed tube. It consists of seed hoper which has two parts, upper one is called grain box and lower one is called feed box. Shuttles are provided to connect these boxes. The seed delivery mechanism consists of a spindle, carrying number of discs with a ring of cups attached to the periphery of each disc. The spindle with its frame and attachment is called seed barrel. When spindle rotates, one disc with its set of cups rotates and picks up few seeds and drops them into small hoppers. The cups have two faces, one for larger seeds and other for smaller seeds. The seed rate is controlled by size of cups and rate at which seed barrel revolves. This type of mechanism is common on British seed drill.

grain box and lower one is called feed box. Shuttles are provided to connect these boxes. The seed delivery mechanism consists of a spindle, carrying number of discs with a ring of cups attached to the periphery of each disc. The spindle with its frame and attachment is called seed barrel. When spindle rotates, one disc with its set of cups rotates and picks up few seeds and drops them into small hoppers. The cups have two faces, one for larger seeds and other for smaller seeds. The seed rate is controlled by size of cups and rate at which seed barrel revolves. This type of mechanism is common on British seed drill.

d) Cell Feed Mechanism: It is a mechanism in which seeds are collected and delivered by a series of equally spaced cells on periphery of a circular plate or wheel.

e) Brush Feed Mechanism: It is a mechanism in which rotating brush regulates the flow of seed from hopper. A number of bullock drawn planters have this mechanism.

f) Anger Food Mechanism: It is distributing mechanism, consisting of an auger which causes a substance to flow evenly in the field, through an aperture at the base or on the side of the hopper, e.g. fertilizer drills.

g) Picker Wheel Mechanism: It is a mechanism in which a vertical plate is provides with radially projected arms, which drop the large seeds like potato in furrows with the help of suitable jaws.

h) Star Wheel Mechanism: It is feed mechanism which consists of a toothed wheel, rotating in a horizontal plane and conveying the fertilizer through a feed gate below the star wheel.

Furrow Openers:

Furrow openers are provided in a seed drill for opening the furrows before dropping the seeds. It may be called a part of seed drill for opening the furrow. The seed tube shifts seeds from feed mechanism into the boot from where they fall into the furrow.

Types of Furrow Openers:

There are various types of furrow openers. These can be chosen and their choice can be influenced by:

The optimum depth of planting which varies widely with different crops.

Soil type

Soil moisture content

Soil temperature and time of year

Some seeds are sensitive to environmental conditions and require care for planting depth.

a) Hoe Type: They are equipped with spring tips and suitable for stony or root-infested soils. They are similar to shovel type and also used for deep placement of seeds if soil is relatively free of trash.

b) Full or Curved Runner: It is a simple device that works well at medium depths in mellow soil free of trash and weeds. It is suitable for average conditions encountered by corn and cotton planters. Horizontal plate type depth gages may be attached to the runner for soft soil.

c) Stub Runner: It is used in rough and trashy ground on corn planters.

d) Shovel Type: These openers are best suited for stony or root infested fields. These shovels are bolted to the flat iron shanks at point where boots are fitted which carry the end of seed tubes. In order to prevent shock loads due to obstructions, springs are provided. It is easy in construction, cheaper and easily repairable. It is very common with usual seed drill.

e) Disc Type: These openers are suitable for trashy or relatively hard grounds. In wet sticky soils they are more satisfactory than fixed openers because they can be kept reasonably clean with scrapers.

Single disc openers are more effective than double disc in regard to penetration and cutting of trash, used generally on grain drills. Single disc openers with mould board attachments are used for furrow planting of grain.

Double disc openers are well adapted to medium or shallow seeding of row crops that are critical in regard to planting depth because depth can be controlled with removable depth bands.

The furrow openers consist of following parts:

Tine: Like cultivator tine.

Shovel: Made of carbon steel having carbon content of 0.5% and minimum thickness of 4.0 mm.

Seed Tube: It is a tube which carries seeds from the metering device to the boot. Seed tubes are provided at lower end of feed cups. They conduct seeds from feed cups to lower lines through suitable boots and furrow openers.

Boot: It conveys seeds from delivery tube to the furrow. It is bolted or welded to the tine. It is a hallow casing into which lower end of seed tube is inserted and to which furrow openers are attached.

Covering Devices:

Various covering devices are drag chains, drag bars, scraper blades, steel press wheels, rubber covered or zero pressure pneumatic wheels, disc hillers etc.

The function of covering device is to place the moist soil in contact with the seed, press the soil firmly around the seeds, cover them to the proper depth and leave the soil directly above the row loose enough to minimize crusting and promoting easy emergence. Thus for grain drills simple drag chains are used which merely cover the seeds with loose soil where there is ample moisture.

In loose sandy soils or for furrow drilling of grains in heavy residues narrow press-wheels with steel or rubber rims are used behind the openers. These wheels increase the crop stand and yield in areas where moisture is a limiting factor.

Open center, concave, steel press-wheels are common for corn and other larger seed crops.

Zero-pressure pneumatic press-wheels are used for vegetable crops. These are continual flexing which make them self cleaning.