Site pages

Current course

Participants

General

Module 1. Role of mechanization and its relationsh...

Module 2. Performance and power analysis

Module 3. Cost analysis of machinery- fixed cost a...

Module 4. Selection of optimum machinery and repla...

Module 5. Break-even point and its analysis, relia...

Module 6. Mechanization planning

Module 7. Case studies and agricultural mechanizat...

Topic 8

Topic 9

Topic 10

Lesson 2. Farm Power Availability and Productivity in India

Mechanization in agriculture holds the key for sustainable development in the terms of increasing the production by timely farm operations, reducing losses, reducing the cost of operations by ensuring better management of costly inputs and enhancing the productivity of natural resources besides it helps in reducing drudgery in farm operations. Mechanized agricultural practices and operations have been adopted by the farming community at varying level of adoption, which represents the varying scenario across different regions in the country. Farm Power is an essential input in agriculture for timely field operations for operating different types of farm equipment and for stationary jobs like operating irrigation equipment, threshers/ shellers/ cleaners/ graders and other post harvest equipment. The source of farm power includes human, animal, tractors, power tillers, diesel engine and electric motor. Information about the availability of these power sources under time-series is very essential in planning and prediction level of farm mechanization as this directly and indirectly provides vast potential for manufacturers, entrepreneurs, sales and repair etc. During last 50 years the average farm power availability in India has increased from about 0.30 kW/ha in 1960-61 to about 1.78 kW/ha in 2011-12. Over the years the shift has been towards the use of mechanical and electrical sources of power, While in 1960-61 about 92.31% farm power was coming from animate sources, in 2009-10 the contribution of animate sources of power reduced to about 13.00% and that of mechanical and electrical sources of power increased from 7.70% in 1960-61 to about 87% in 2009-10. Food grains productivity is positively associated with unit power availability. It is visualized that the additional requirement of food grains in future will be met, to a great extent from the demand of tractors, power tillers and other machinery.

The country witnessed unprecedented growth in agriculture that helped country to graduate from hunger to self-sufficiency in food grains by increasing the food grain productivity from 0.636 t/ha in year 1965-66 to 1.798 t/ha in 2009-10, resulting for export with surplus. This growth is mainly due to the agricultural technology during green revolution period which is back-up by agricultural scientists including agricultural engineering, supported by positive policy support, liberal public funding for agricultural research and development and un-tired work of farmers. Power is needed on the farm for operating different tools, implements and during various farm operations. While mobile power is used for doing different field jobs, the stationary power is used for lifting water and operating irrigation equipment; operating threshers, shellers/decorticators, cleaners, graders and for other post harvest operations. The mobile farm power comes from human, draught animals, power tillers, tractors and self-propelled machines; whereas the stationary power is obtained from oil engines (diesel, petrol, kerosene) and electric motors. Availability of adequate farm power is very crucial for timely farm operations for increasing production and productivity and handling the crop produce to reduce losses. With the increase in intensity of cropping the turnaround time is drastically reduced and it is not possible to harvest and thresh the standing crop, on one hand, and prepare seed bed and do timely sowing operations of subsequent crop, on the other hand, in the limited time available, unless adequate farm power is available. Similarly for precision farming, increasing area under irrigation, conservation tillage, straw management and diversification in agriculture, more power is required. There has been close nexus between farm power availability and increased productivity. Those states where availability of farm power is more have, in general, higher productivity as compared to other States.

The key factor in farm mechanization is the introduction of mobile mechanical power, i.e., tractor, power tiller and associated machinery. As know that Sardar Joginder Singh (1897-1946), then Agriculture Minister in the Punjab Government (1926-37), introduced the steam tractors in India in 1914 for reclamation of wasteland and eradication of ‘Kans’. Demand of tractors in the country was met through import until 1961 when Eicher Tractors Ltd. and Tractors and Farm Equipment Ltd started manufacturing tractors with foreign collaborations. To meet the additional domestic demand, importation continued up to 1977. Meanwhile many other industries started manufacturing tractors with foreign know how such as Gujarat Tractors Ltd (1963), Escorts Ltd (1966), International Tractors (India) Ltd. (1966), and Hindustan Machine Tools Ltd (1977). Punjab Tractors Ltd. started their production with indigenous technology in 1974. Many more industries started manufacturing tractors since then with indigenous and foreign know how.

Sources of power: The different sources of power available on the farm for doing various mobile and stationary operations are as under:

Mobile Power

Human (men, women, children)

Draught animals (bullocks, buffaloes, camels, horses and ponies, mules and donkeys)

Tractors

Power tillers

Self propelled machines (combines, dozers, reapers, sprayers etc.)

Stationary Power

Diesel/oil engines (for pump sets, threshers, sprayers and other stationary operations)

Electric motors (for pump sets, threshers, sprayers and other stationary operations)

Human Power: Agriculture has been the main occupation of the rural people and largely dependent on use of animate power sources. Human energy is predominantly used for all operations in agriculture. Before green revolution, animate energy had been widely used for various farm operations like seedbed preparation, sowing, inter-cultivation, harvesting, threshing and transportation to and from the field. Wider job opportunities in urban areas have set in a trend of rural youth preferring to take up other profession than cultivation. However, in specific situations as hill agriculture, shifting cultivation, tal and diara land cultivation, human energy would continue to serve as principal source of energy. Even in specialized operations as rice transplanting, harvesting of cotton, horticultural and plantation crops, human power is the only source of energy in agriculture.

The labour/land ratio has been steadily increasing over time and thus technological changes through mechanization process have been land-saving in nature with focus on increasing land productivity. Mechanization process in India thus did not follow the process of creating surplus labour from agricultural sector for consumption in the industrial sector, as had been in the cases of countries like USA and Japan.

While the population of agricultural workers as percentage of rural population has gone down from about 69.4% in 1951 to about 55% but in absolute terms, due to increase in overall population, the number of agricultural workers available in rural areas has increased from 116 million numbers in 1960-61 to 243 million numbers in 2009-10 and thereby registered an annual compound growth rate of about 1.5% during the last 50 years. These agricultural workers are engaged in different farm operations and depend on agriculture for their livelihood, even when they are not fully employed throughout the year. Due to too much involvement of labour in different farm operations, the cost of production of most of the crops in our country is quite high as compared to developed countries.

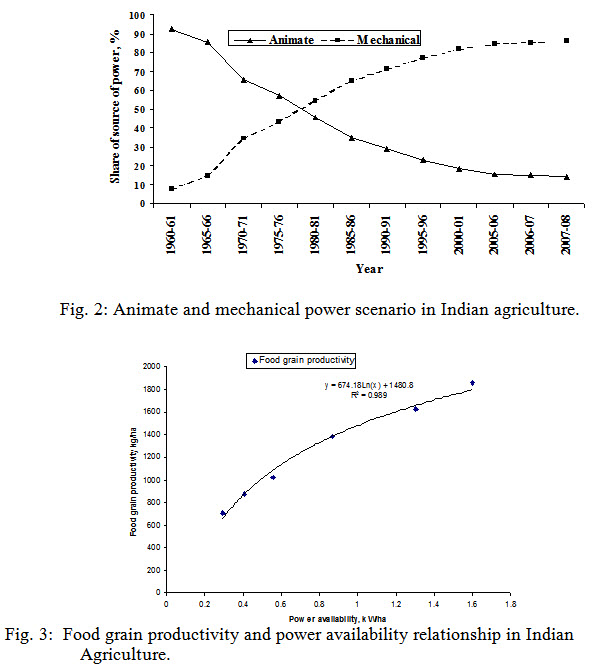

Human power availability for agriculture had been 0.043 kW/ha in 1960 and reached 0.162 kW/ha in 2000 at an annual compound growth rate of 3.37 per cent. The growth rate decreased to –1.4 per cent between 2000 and 2009 with a reduced power availability of 0.145 kW/ha in 2009-10 (Fig. 1).

Draught Animal Power (DAP): Draught animal power, available mainly as progenies of milch animals, has long remained an important source of tractive energy for production agriculture, rural agro-processing and transport in India and other developing countries of Asia, Africa and Latin America. Traditional agriculture in India largely depended upon this power source for farm operations like tillage, sowing, weeding, water lifting, threshing (by animal trampling), oil extraction, sugarcane crushing and transport. With modernization of agriculture production systems and use of mechanical power sources, draught animal use has drastically reduced in power intensive operations as water lifting, oil extraction and threshing. The choice of farm power to be used for an operation is largely decided by the available time period, alternatives available (including custom hiring services) and associated economics. In sloppy hill regions and on small farms machines like tractor or combine are difficult to operate, and thus draught animal use besides human is likely to continue as major power source. Increased cost of maintenance of animals has also brought in compulsions among the farmers to reduce draught animal ownership as far as practicable. Apart from the economic importance, livestock still continues to have symbiotic bond with rural people.

Draught animals, particularly bullocks, are still the predominant source of mobile power on about 60% of the cultivated area consisting of about 85 million ha. They are very versatile and dependable source of power and are used in sun and rain under muddy and rough field conditions. They are born and reared in the village system and maintained on the feed and fodder available locally. They are ideal for rural transport where proper roads are not available. They reduce dependence on mechanical sources of power and save scarce petroleum products. Their dung and urine are also used as indirect source of energy-farmyard manure, biogas. They also help in maintaining ecological balance. Under Indian conditions where majority of the people are vegetarian and even amongst non-vegetarians, majority of them don’t eat beef, draught animals as byproduct of milch animals, will continue to be available for draught purposes in future also. About 4-5 decades back most of the farm operations, water lifting, rural transport, oil extraction, sugarcane crushing, chaff cutting etc, were being done using draught animals only. But with the modernization of agriculture, development of pucca roads connecting village and availability of electricity in those villages, most of the jobs earlier being done using draught animals, except field operations, are now being done using other convenient and cheaper options. Over the years the annual use of draught animals is going down. While earlier a pair of animals was being used for about 1200-1800 hours annually, their average annual use has now come down to about 250-500 h only, that too for tillage, sowing, weeding and a little bit of rural transport on kuchha roads. The time series population of draught animals during 1960-61 to 2007-08 is given in Table 1, which shows that the population of draught animals during the last 20 years has been going down. This declining trend of draught power was more visible especially in those states where the demand of tractors and power tillers has gone high. It has been observed that on an average a tractor is replacing about 5 pairs and power tiller about 2 pairs of animals. Draught animal population, mainly derived from bovines, was 80.40 million in 1960-61 and reduced to 52.65 million numbers by 2009-10 during the same period. Although the bovine population in the country has been steadily increasing, the population of animals actually available for work has shown a different trend over the period of time.

With decreasing population of draught animal, and a very slow increase in net-cropped area in the beginning, draught animal power availability in India decreased from 0.229 to 0.224 kW/ha between 1960 and 1970. During the next decades, the power availability further reduced to 0. 200 kW/ha in 1980, 0.162 kW/ha in 2000 and 0.145 kW/ha in 2009 (Fig. 1).

Mobile Power from Tractors and Power Tillers: For meeting the increased demand of mobile power for timely farm operations and increased intensity of cropping, additional power is available mainly from tractors and power tillers. Self-propelled reapers and combines also provide mobile power specially for harvesting operations. In 1947 central and state tractor organizations were set up to develop and promote the supply and use of tractors in agriculture and up to 1960, the demand was met entirely through imports. There were 8,500 tractors in use in 1951, 20,000 in 1955 and 37,000 by 1960. Local production began in 1961 with five manufacturers producing a total of 880 units per year. By 1965 this had increased to over 5000 units per year and the total in use had risen to over 52,000. By 1970 annual production had exceeded 20,000 units with over 1,46,000 units working in the country. Five new manufacturers have started production since 1997. In 1998 Bajaj Tempo, already well established in the motor industry, began tractor production in Pune. In April of the same year New Holland Tractor (India) Ltd launched production of 70 hp tractors with matching equipment. Larsen and Toubro have established a joint venture with John Deere, USA for the manufacture of 35-65 hp tractors at a plant in Pune, Maharashtra and Greeves Ltd is producing Same tractors under similar arrangements with Same Deutz-Fahr of Italy.

India presently is the largest manufacturer of tractor in the world. There are more than 20 manufacturers of tractors in the country producing about 60 models of tractors in different hp ranges. Tractor population in India has grown from 0.037 million in 1960-61 to 3.464 million units in the year 2009-10 at an annual compound growth rate of about 10 per cent during the last 50 years. Farm power availability from tractors has consequently increased from 0.007 kW/ha in 1960 to 0.218 kW/ha in 1990 at an annual compound growth rate of about 12 per cent. The growth rate in the next decade decreased to 8 per cent. Farm power availability in the year 2000 was 0.47 kW/ha, reaching to 0.639 kW/ha in 2009 at an overall growth rate of 9.65 per cent during the last 49 years (Fig. 1).

Power tiller, or two-wheel tractor, came in India with import of two units from Japan in 1961.There are mainly 2 manufacturers of power tillers in the country producing about 6 models in the range of 5.97-8.95 kW (8-12 hp). In addition to them there are many others who are importing Chinese make of power tillers and selling in the country. The total sale of power tillers in the country during 2007-08 was 21106 units. The major sales of power tillers are in the States of West Bengal, Tamil Nadu, Karnataka, Assam, Kerala, Orissa and Maharashtra. Farm power availability from power tiller has consequently been meagre. It was 0.001 kW/ha in 1981, and rose to 0.05 kW/ha in 2000 and 0.008 kW/ha in 2009. Thus, it increased by about 8 times during the period of 1980 to 2009.

Stationary Power from Diesel Engines and Electric Motors: Stationary power sources in agriculture comprise of diesel engines and electric motors used for irrigation equipment, operating threshers and other stationary machines. Diesel engine and electric motor are widely used by the farmers mainly for lifting irrigation water, apart from operating stationary farm machines like threshers and chaff cutters. The populations of these prime movers have increased tremendously since the green revolution.

Diesel engine population in the country increased 34.35 times between 1960-61 and 2009-10. While the annual compound growth rate had been 11.86 per cent during the period 1960-61 to 1985-86, with increased availability of electricity it reduced to 7.65 per cent during the period of 1960-61 to 2009-10. Farm power from diesel engines increased from 0.009 kW/ha in 1960 to 0.246 kW/ha in 2000 and further to 0.312 kW/ha in 2009, registered an annual compound growth rate of 7.50 per cent during the last 49 years.

The rural electrification programme launched by the Government of India in the mid sixties undertaken through the Rural Electrification Corporation has helped in making available electricity to 18.5 per cent villages in 1970-71 and increased to almost 100 per cent villages by 2007-08. Preferential supply to rural sector at subsidized price has led to rapid increase in use of electric motors in the agricultural sector. Electric motor population thus increased 79 times between 1960-61 and 2007-08 at an impressive annual compound growth rate of 9.53 per cent. Farm power availability consequently increased exponentially from 0.006 kW/ha to 0.412 kW/ha between 1960 and 2009 with an annual compound growth rate of about 9 per cent during the last 49 years.

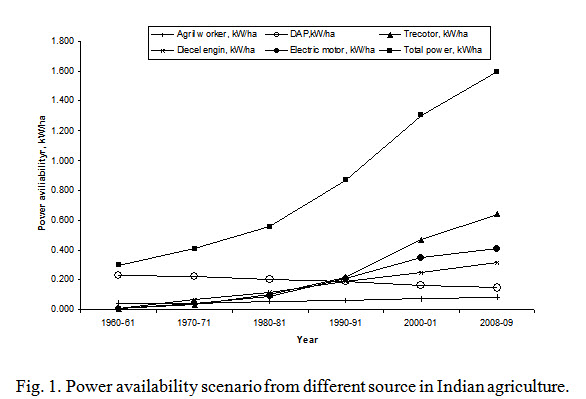

Animate and Mechanical Power Scenario: For adoption of higher level of technology to perform complex operations within time constraints and with comfort and dignity to the operators, mechanical power becomes essential. Thus, the extent of use of mechanical power serves as an indicator of acceptance of higher level of technology on farms. Over the years the shift has been towards the use of mechanical and electrical sources of power, while in 1960-61 about 92.31% farm power was coming from animate sources. In 2008-09 the contribution of animate sources of power reduced to about 14.20% and that of mechanical and electrical sources of power increased from 7.70% in 1960-61 to about 85.30% (Fig. 2).

Farm Power Availability and Food Grains Productivity Relationship: Food grains productivity in India has increased from 0.710 t/ha in 1960-61 to 1.856 t/ha in 2008.09, while farm power availability has increased from 0.296 kW/ha to 1.600 kW/ha during the same period. Thus, food grains productivity is positively associated with unit power availability in Indian agriculture (Fig. 3). The relationship between food grains productivity and unit farm power availability for the period 1960-61 to 2008-09 were estimated by log linear function, with highly significant value of coefficient of determination (R2) as following:

Yfgs = 674.18 Ln(Xps) + 1480.8

R2 = 0.989

Where,

Yfgs = food grains productivity of India, kg/ha, and

Xps = power availability in India, kW/ha

This indicates that productivity and unit power availability is associated linearly. It is also evident that farm power input has to be increased further to achieve higher food grains production, the composition of farm power from different sources to be properly balanced to meet its timely requirement for various farm operations.