Site pages

Current course

Participants

General

MODULE 1. Planning of Farmstead

MODULE 2. Physiological Reactions of Livestock

MODULE 3. BIS Standards

MODULE 4. Farm Structures

MODULE 5.

MODULE 6. Rural Living and Development

MODULE 7. Water Supply

Topic 8

Topic 9

Topic 10

LESSON 9. Machinery and Implements Shed

1.1 Introduction

Farm implements and machineries vary from to farm. Any a common storage shed for these are essential to protect them from weathering action. The sheds Need no enclosure no all sides. Hence angle iron posts or masonry pillars may be provided for supporting the corrugated sheet roofing. A lean to roof with a rear end enclosures or gabled roof with only end enclosures to support the Roof may also be adopted.

A raised ground itself serves serves as satisfactory flooring. But for cleanliness well packed gravel flooring will be sufficient. Ramps should be provided to allow movement of machineries over the floor. Where a separate workshop is not provided on a farm, necessary platforms, benches etc., may be provided in the machinery shed itself to facilitate cleaning. Servicing and repair works of the farm machineries.

Fig.6.1. implements shed for the smaller farm

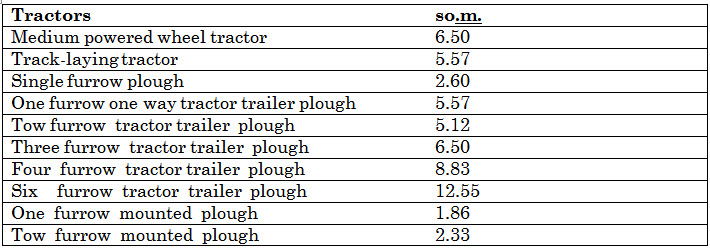

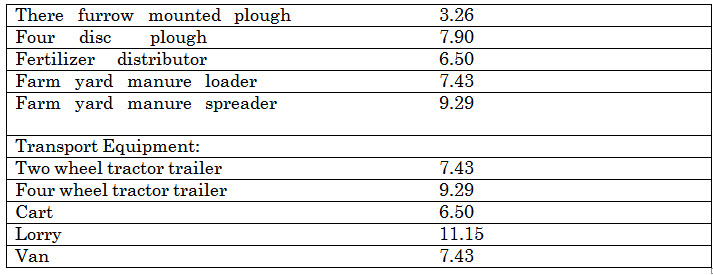

Table.6.1. average space requirements of farm implements and machinery.

HEIGHT REQUIREMENT OF LARGE TYPES IMPLEMENTS MACHINERIES AND TRACTORS:

Medium power wheel tractors 2.4 m (8 ft.) over exhaust and air intake pipe. Tract sugar beet equipment 2.1 m over exhaust and air intake pipe.

Complete harvester 3 m

Grass equipment In metres

Pick up baler 2.4

Stationary baler 3.0

Green crop loader 3.6

Elevator (folded) 2.4