Site pages

Current course

Participants

General

MODULE 1. Planning of Farmstead

MODULE 2. Physiological Reactions of Livestock

MODULE 3. BIS Standards

MODULE 4. Farm Structures

MODULE 5.

MODULE 6. Rural Living and Development

MODULE 7. Water Supply

Topic 8

Topic 9

Topic 10

LESSON 15. Cost Estimation, Repair and Maintenance of Roads

1. ROAD CONSTRUCTION

1.1 EARTHEN ROAD

The roadway after peg marking is first cleared of all the vegetations by removing the top, loose soil. The soil excavated nerby or brought from borrow pits in spread over uniformly to the required width in layers not exceeding 15 cm (6 inch) thick. All the clods and lumps should be crushed and spread. Red earth or clayey soil width sand mixed in a suitable proportion can be better adopted for earthen roads. The soil spread in layers is consolidated by rolling with a 6 ton roller, adding sufficient quantity of water. Excess water will make the surface slushy and the rolling difficult, since the wet soil will stick to the wheels and the consolidation will not be effective. A camber of 1 in 24 is given for earthen roads.

Soils which contain not more than 30 percent of sand and 70 percent of clay make a first class unmetalled road if properly maintained. Besides its cheapness, the road has got a better resilience than many of the roads. But the surface is easily disturbed by the downpour of rain and under iron tyred traffic. Hence the maintenance should be carried out often and the ruts and pot holes wherever formed should be attended to immediately by plugging and rolling them then and there.

1.2 GRAVEL ROAD:

Gravel road is an improved type of earthen road in which gravel is used instead of earth. The gravel used should be well graded and may vary from 5 cm to 2 cm. (2” to ¾”) in size. Gravel together with soil is useful for road making as the soil will act as a binding material.

On a prepared sub grade a uniform layer of gravel for 7.5 cm to 10.0 cm (3 inch to 4 inch) thickness is spread over to the full width and it is consolidated using a 3 to 5 to roller. A moderate sprinkling of water will be of help to aid compaction. If the thickness is to be increased another layer may be spread over the first one and consolidated in the same manner. The camber given for gravel road is 1 in 28 to 1 in 32.

A gravel road has got the following advantages over an earthen road.

A good gravel road is economical and suits all weather

The construction is easy

The surface is smooth and it easy for driving on the road and

It is suited even for heavy traffic when the thickness is suitably designed.

1.3 WATER BOUND MACADAM ROAD

The water bound macadam road of metalled road is the most common type of road in India. The rod way after being bared of the vegetations etc., is shaped to the designed sections to the full width giving side slope or fall on either side. On this a layer of sand for the designed thickness to a maximum of 10 cm (4 inch) is spread evenly and consolidated well. Over the sand blanket soling stones are laid. The soiling stones may be broken brick bats, boulders of granite, laterite and kunker and they should be round shaped. The stores shold be laid on their broad base with undulations upward. They are hand packed to the full width of road taking care to stagger the joints. A binding material such as gravel is spread over the sling stones and the dry surface is rolled with a roller. The road may be even opened for traffic for a short period.

When the sub grade itself is hard, the provision of soling stones may not be essential. The metalling (wearing) can be proceeded with straight away on the sub grade formed with sand or gravel.

METALLING

The broken metal generally of 3.75 cm to 2.0 cm (1.5” to ¾”) size is spread to the required thickness to the full width, with sufficient camber. The metal spread is hand packed so as to leave no hollow space. It is then rolled dry starting from the edges and proceeding towards the centre so that in each successive run, half the width of the previous rolling is again rolled. When the surface is compacted watering is done and it is again rolled to compaction. The rolling before and after addition of water shall be ordinarily 2 to 3 times.

Over the surface of the road, red earth or screened dust from the metal or gravel is spread to 1.25 cm (½ inch) thickness and it is rolled about 10 to 16 times or until a loaded country cart makes no impression on the surface. Gravel or red earth acts as a blining material and hence this is known as ‘blinding’. During the rolling, the surface in watered and the slurry comes to the surface and is evenly spread with brooms. The final top dressing layer of sand to 6 cm (¼ inch) thicknessis spread evenly and finished with a final rolling. The road surface thus finished is kept moist for about a fortnight after opening to traffic.

When compared to the earth and gravel roads, the water bound macadam roads are smooth and some what more resilient. The traction oven them is good. They afford better hold for wheels so that slipping or skidding of vehicles is avoided. They are not slippery even when they are wet.

1.4. POT HOLE REPAIRS

Wherever holes or ruts appear they shall be atonce repaised by cutting out to the full depth of the metal in a rectangular form and filling it with fresh material. The filling is similar to the new road construction. Where the pot holes are too many, it is better to relay the whole surface.

1.5. RELAYING OF WEARING COAT

While commencing the relaying, the first thing to be done is picking the old metalled surface to 5 cm to 10 cm (2 inch to 4 inch) depth. The picking is done to make the surface even and to have a proper bedding for the new materials. The relaying of metal in also similar to the construction of new metalled roads.

1.6. BITUMIN ROAD

Bitumin or tar roads having their top surface finished with broken metal binded by bitumen or tar. An old surface with a sufficiently strong crust of water bound macadam serves as an excellent foundation for the bitumen or tar surfacing.

The material used for bitumen roads are hard broken stone and bitumen. The broken stones should be durable, the size varying from 19 mm to 13 mm ( ¾” to ½”). The granite broken stones are best suited for bitumen roads. Bitumen is the binding material used to coat the aggregates and to provide adhesive property that is necessary to prevent disintegration and protecting the water contact.

CONSTRUCTION

All bituminous types of surface belong to either of the two groups depending on whether the binder is tar or bitumen

The water bound macadam road to be treated with bitumen or tar should be smooth, dry and free from pot holes or unevenness. Immediately proceeding the surface treatment, it should be swept clen and kept free from dust. Bituminous material is then applied to the cleaning surface from sprayers at the rate of 1 kg per 1 sq.m. (20 lit/100 sq. ft.) area. The careened, dust free, dry, hard broken stone is mixed with bituminous material at the rate of 124 kg per 1 cu.m. of stones (31/2 1b/1 cuft. of stone) in the mixture and placed on the surface and spread evenly so the specified thickness. The surface is then hadn picked to avoid.

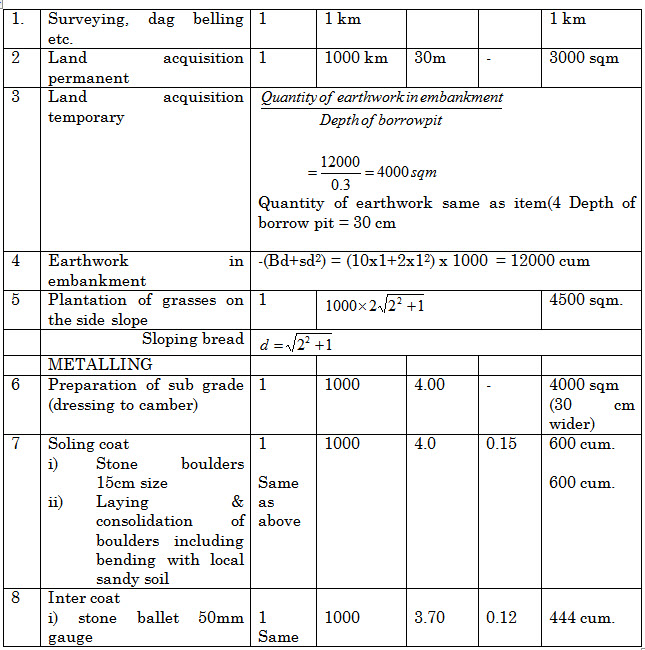

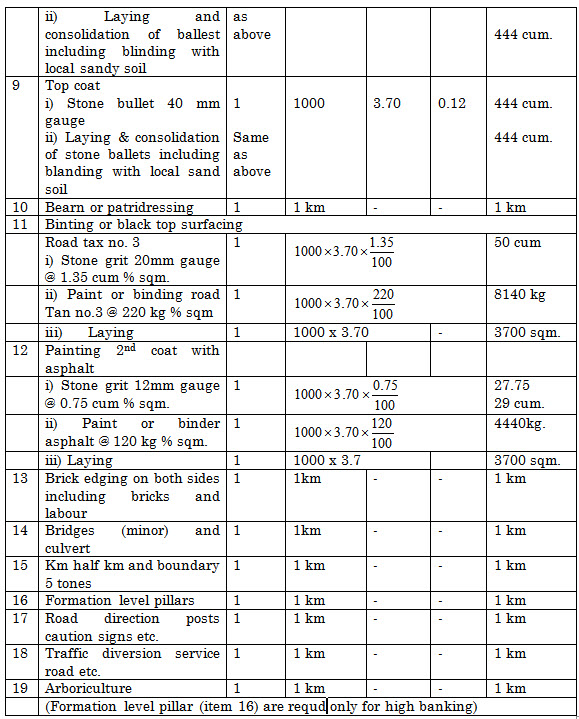

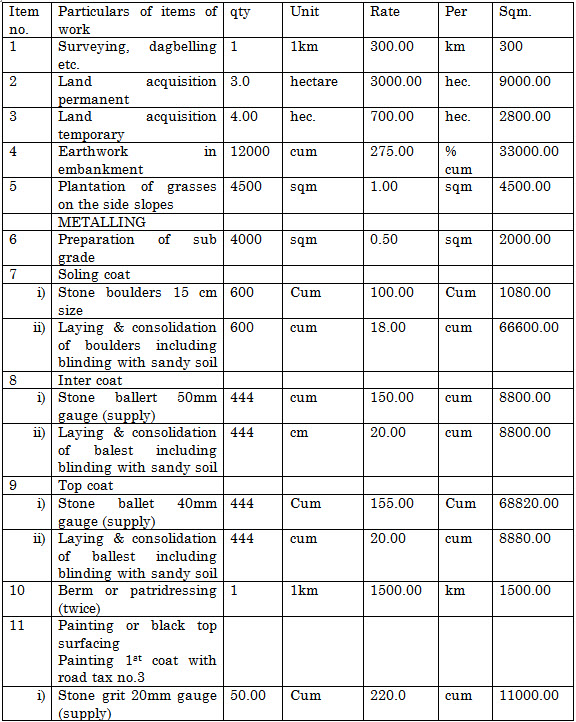

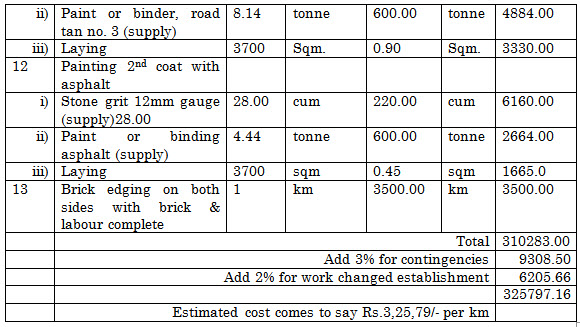

Prepare a detailed estimate for the construction of a view state Highway for 1km length. The formation width of road is 10m, average height of bank is 1 metre and side slope 2:1. The metalled width is 3.70m and three coats of metalling are to be provided as per c/s. The surface shall be finished with two coats of painting. Assume other data and suitable rates.

Details of measurements and calculations of quantities