Site pages

Current course

Participants

General

Module 1. Introduction to human engineering

Module 2. Human performance and responses

Module 3. Working environment and work space design

Module 4. Rehabilitation scheme and DMR Act

Topic 5

Topic 6

Topic 7

Topic 8

Topic 9

Topic 10

Lesson 1. HUMAN FACTORS IN SYSTEM DEVELOPMENT - CONCEPTS OF SYSTEM

1.1 Introduction

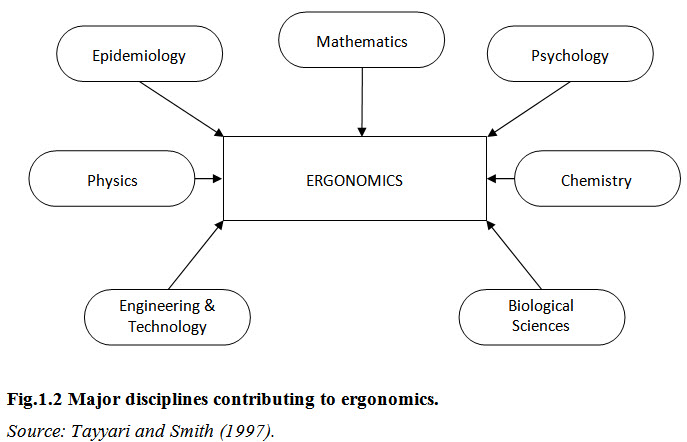

The word ERGONOMICS is derived from the two GREEK words: ERGO (means work) and NOMOS (means rules or laws). Thus; Ergonomics is the scientific discipline mainly concerned with understanding of the interaction of humans, and the scientific design profession that applies theory, principles, data and methods to design and improve the work system involving machine or job with human (i.e. operator) as an integral system.

Ergonomics is also sometime called as:

-

Man-Machine-Environment System, or

-

Human Factors Engineering, or

-

Human Engineering.

However; ERGONOMY it is not to be confused with AGRONOMY, which is related to Crop Sciences.

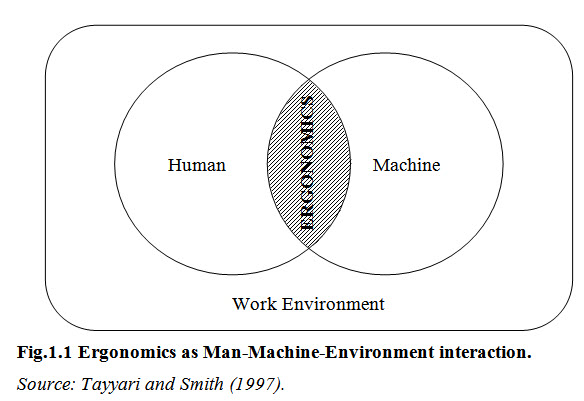

Ergonomics or Man-Machine-Environment System deals with the machine or job, its operator and working environment as a complete system affecting the intended work performance

The working environment may involve workspace, controls, ambient environment, noise, dust, vibrations, smoke and gases, light, safety concerns, etc. Ergonomics is an application of Medical and Engineering Sciences principles related to human factors in the task concerned

1.2 Definition of ergonomics

-

Human-factors engineering is the application of human factors information to the design of tools, machines, systems, tasks, jobs, and environments for safe, comfortable and effective human use (Chapanis, 1996).

-

Ergonomics is the scientific discipline concerned with the understanding of interactions among human and other elements of a system, and the profession that applies theory, principles, data and methods to design in order to optimize human well-being and overall performance (International Ergonomics Association, 2000).

-

Ergonomics is the design and engineering of human-machine systems for the purpose of enhancing human performance (Dempsey et al., 2000).

-

Human factor Ergonomics can be defined as the science of design, testing, evaluation and management of human system interaction according to the human-system compatibility requirements (Karwowski, 2005).

-

Human factors/ Ergonomics is the scientific discipline concerned with understanding interactions among humans and other elements of a system. It is also a profession that applies theory, principles, data and methods to design in order to optimize human well being and overall system performance (Zink, 2006)

1.3 The operator-machine-environment system approach

The human has a limiting capability as a power of source in comparison to the engine/ machine. However, it has a distinct advantage in terms of its intelligence and decision making as per need. The operator acts as a core of the system. Operator uses his sensory system to perceive the environment, takes decision based upon information available, and finally takes appropriate action for desired output. If the task is new and not well known to operator then the decision making process is very slow. For routine and well known task, decisions are very quick and accurate. Stress is one of the variables that affect operator perception, decision making, and response selection. Many factors including operator’s age, training, motivation, etc. affect the success of task performance.

The machine characteristics that are involved in the system are its features, controls, displays, power availability, speed of operation, seat, vibrations, noise, exhaust, visibility, safety features, etc. Workspace, controls layout and display arrangement affects the operator capability to a large extent. For example, a tractor seat is designed for comfort of operator and easy accessibility of controls like brake, steering, gears, clutch, etc.

In the Ergonomics application, “environment” is used to conceptualize the task as well as the context in which it is performed. The ambient environment is only one of the factors covered under this. Noise, vibrations, dust, smoke, field conditions, are some of the other major environmental factors that come into play, thereby affecting task performance.

1.3.1 Relative advantages of man and machine

Man and machine have their distinct comparative advantages over each other. In a system, these advantages can be utilized for their optimum use. Table 1 lists comparison of characteristics of man and machine.

Table 1.1 Relative advantages of men and machine

|

Characteristic |

Machine |

Man |

|

Speed |

Much faster |

Quickest reaction approx. 0.05 second |

|

Power |

Consistent at any level, large, constant standard forces. |

2.0 hp for about 10 seconds 0.5 hp for few minutes 0.2 hp for continuous work over a day |

|

Consistency |

Ideal for: routine; repetition; precision. |

Not reliable: should be monitored by machine. |

|

Complex activities |

Multi-channel |

Single-channel. |

|

Memory |

Best for literal reproduction and short term storage |

Large store, multiple access. Better for principles and strategies. |

|

Reasoning |

Good deductive |

Good inductive. |

|

Computation |

Fast, accurate, poor at error correction |

Slow subject to error. Good at error correction. |

|

Input sensitivity |

Some outside human senses, e.g., radioactivity

Can be designed to be insensitive to extraneous stimuli. |

Wide energy range (1012) and variety of stimuli dealt with by one unit: e.g. eve deals with relative location, movement and colour. Good at pattern detection. Can detect signals against high levels of background noise. Affected by heat, cold, noise and vibration (exceeding known limits) |

|

Overload reliability |

Sudden breakdown. |

Gradual degradation. |

|

Intelligence |

None. |

Can deal with unpredicted and unpredictable: can anticipate. |

|

Manipulative abilities |

Specific. |

Great versatility. |

Source: Zander (1973)

1.4 Importance of ergonomics

Ergonomics is the science of designing equipment, the workplace and even the job to fit the worker. Ergonomics is the study of designing equipment and devices that best suited the human body, its movements, and its cognitive abilities. It deals with the physical work environment, tools and technology design, workstation design, job demands and physiological and biomechanical loading on the body. Objective of ergonomics is not only to improve work performance but also to improve human comfort and safety. If ergonomic aspects are not considered, the performance of the system will be poor and the effective working time will be reduced. The goal of ergonomics is to design workplace to conform to the physiological, psychological, and behavioural capabilities of workers. Ergonomics can contribute to the solution of a large number of problems related to safety, health, comfort and efficiency.

1.4.1 Importance of ergonomics in agriculture

In developing countries like India, a large proportion of working population is dependent on agriculture. Also, human workers constitutes as one of the important source of farm power. Besides, human workers also operate animal drawn equipment, tractors, power tillers and other self-propelled machines. The ergonomic aspects during application in agricultural machinery are of great importance as the operator has to operate the machine mostly in field. The physiological as well as psychological fatigue affects performance of the operator. Therefore in agriculture, the application of ergonomics help in increasing the work performance, productivity, efficiency and work duration of farm workers with enhanced comfort and safety.

1.5 System Goals

The goal of ergonomics can be understood in terms of its five main principles, which are:

Productivity and performance

Comfort

Ease of use

Safety

Aesthetics

These principles can be broken down into three areas:

Physical ergonomics is concerned with the way the body interacts with the worker’s tools (anything from shovels to chairs to personal computers) and their effects on the body such as posture, musculoskeletal disorders, repetitive disorders, workplace layout and workplace health and safety.

Cognitive Ergonomics relates to the way the mind processes information it is presented with and associated motor functions, memory usage, decision-making and other mental workloads. Study of these factors and the interaction between humans and the data presentation can improve everything from the placement of signs, the visibility and recognition and retention of the data.

Organizational Ergonomics is concerned with optimizing the workplace, teamwork, performance assessment and quality management. It includes office design, shift (work hours) management, crew resource management, teamwork, virtual organizations, tele-work, addressing communication, and quality management in the workplace.

Suggested readings:

Chapanis A. 1996. Human Factors in System Engineering. John Wiley & Sons, New York.

Tayyari F. and Smith J. L. 1997. Occupational ergonomics–Principles and Applications. Chapman & Hall, London.

Dempsey, P.G., Wogalter, M.S. & Hancock, P.A. 2000. What’s in a name? Using terms from definitions to examine the fundamental foundation of human factors and ergonomics science. Theoretical Issues in Ergonomics Science.1, 1, 3-10.

Karwowski W. 2005. The Dicipline of Ergonomics and Human Factors. University of Louisville, Kentucky.

Zander J. 1973. Principles of Ergonomics. Agricultural University, Wageningen, Netherlands.

Zink K.J. 2006. Human factors, management and society. Theoretical issue in ergonomics science. Taylor and Francis, London.7, 437-445.