Site pages

Current course

Participants

General

Module 1. Classification of Farm Power Sources

Module 2. Classification of IC Engines & Therm...

Module 3. Performance Characteristics

Module 4. Engine Components

Module 5. Engine Operating System

Module 6.:Engine Fuel System

Module 7. Engine Governor

Module 8. Engine Cooling & Lubrication system

Module 9. Engine Ignition System

LESSON 8. Components : Function & Material of Construction

Engine components: Every component has its own significance in the smooth and desired functioning of an engine. The various components are constructed and manufactured keeping in view the design and performance features of the engine.

Block: Body of engine containing the cylinders made of cast iron or aluminum. The engine block is machined with multiple tools (manually or CNCs, the computer numerically machines) to fix the other components. The block of water cooled engines includes a water jacket cast around the cylinders. In air cooled engines the exterior surface of the block has cooling fins.

Head: The component that closes the end of cylinders, usually containing part of the clearance volume of the combustion chamber is called head. The head is usually made up of cast iron or aluminum, and bolts to the engine block. The head contains spark plug in the SI engines, and the fuel injectors in CI engines and some SI engines. Most modern engines have the valves in the head and many have the camshafts also positioned there (overhead valves and over head cam).

Head gasket: It is the gasket that serves as a sealant between the engine block and the head where they bolt together to avoid any leakage and pressure loss. The gaskets are usually made in sandwich construction of metal and composite materials. Some engines use liquid head gaskets also.

Cylinders: The circular cylinders in the engine block in which the pistons reciprocate back and forth. The walls of the cylinder have highly polished hard surfaces. Cylinders may be machined directly in the engine block or hard metal (drawn steel) sleeve may be pressed into the softer metal block also known as liners. Sleeves may be dry sleeves, which do not contact the liquid in the water jacket or wet sleeves which form part of the water jacket. With the advancement of engines design and manufacturing techniques being used and also due to additional advantages, the replaceable liners are getting more popularity these days.

Piston: The cylindrically shaped mass that reciprocates back and forth in the cylinder, transmitting the pressure forces being generated by the fuel burnt in the combustion chamber for rotating the crankshaft is called piston. The top of the piston is called crown and the sides are called skirt. The face on the crown makes up one wall of the combustion chamber and may be a flat or highly contoured surface. Some pistons contain an indented bowl in the crown which makes up a large percent of clearance volume. Pistons are made of alloy steel. Pistons have lower thermal expansion which allows for higher tolerances. Aluminum pistons are lighter and have less mass inertia. Sometimes synthetic or composite materials are used for the body of the piston, with only the crown made of metal. Some pistons have a ceramic coating on the face.

Piston pin : Pin fastening the connecting rod to the piston is called piston pin and also called wrist pin.

Piston rings: These are the metal rings that fit into circumferential grooves around the piston and form a sliding surface against the cylinder walls. Near the top of the piston are usually two or more compression rings made with highly polished surfaces. The purpose of the rings is to form a seal between the piston and cylinder walls and to restrict the high pressure gases in the combustion chamber from leaking pass the piston into the crankcase (known as blow-by). Below the compression ring s on the piston is at least one oil ring, which assists in lubricating the cylinder walls and scrapes away excess oil to reduce oil consumption.

s on the piston is at least one oil ring, which assists in lubricating the cylinder walls and scrapes away excess oil to reduce oil consumption.

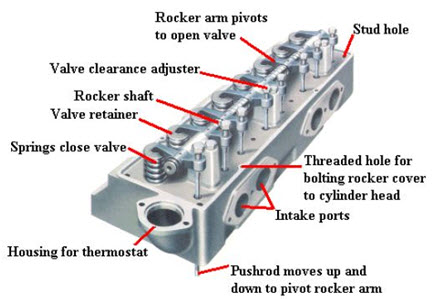

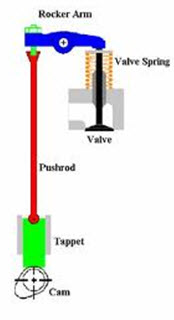

Valves : These are used to allow flow of air and fuel or its mixture into and burnt/exhaust gases out of the cylinder at the proper time in the four stroke cycle engines. Most engines used poppet valves which are spring loaded closed, and pushed/open by camshaft action. Valves are mostly made of forged steel. Surfaces against which valves close are called valves seats and are made of hardened steel or ceramic. Two stroke cycle engines have ports (slots) in the side of cylinder walls instead of mechanical valves.

Push rods: It is the mechanical linkage between the camshaft and valves on over head valves engines used to operate the valve mechanism. Push rods have oil passages through there length as part of a pressurized lubrication system.

Camshaft: Rotating shaft used to operate the valves (intake and exhaust) at the proper time in the engine cycle either directly or through mechanical or hydraulic linkage (push rods, rocker arms, and tappets) is know as camshaft. Mostly engines have camshafts in the crank case but modern automobile engines have one or more camshafts mounted in the engine head known as overhead cams. These are generally made of forget steel or cast iron and driven by means of a belt or chain (timing chain). To reduce weight, some cams are made from a hollow shaft with the cam lobes press-fit on. In four stroke cycle engines the camshaft rotates at half engine speed.

Crankshaft: The rotating shaft through which engine work output is supplied to external systems is called crankshaft. The crankshaft is connected to the engine block with the main bearings. It is rotated by the reciprocating pistons through connecting rods connected to the crankshaft, offset from the axis of rotation. This offset is sometimes called Crankthrow or crank radius. Most  crankshafts are made of forged steel, while some are made of cast iron.

crankshafts are made of forged steel, while some are made of cast iron.

Connecting rod: Linkage used for connecting the piston with rotating crankshaft is called connecting rod. It is usually made of steel alloy forging or aluminum. Connecting rod is fastened to crankshaft with the help of bearing.