Site pages

Current course

Participants

General

Module 1. Classification of Farm Power Sources

Module 2. Classification of IC Engines & Therm...

Module 3. Performance Characteristics

Module 4. Engine Components

Module 5. Engine Operating System

Module 6.:Engine Fuel System

Module 7. Engine Governor

Module 8. Engine Cooling & Lubrication system

Module 9. Engine Ignition System

LESSON 12. Valve Timing

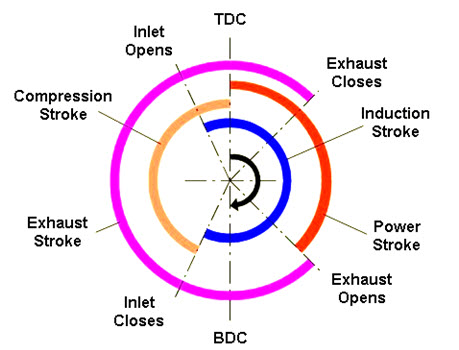

Opening and closing of inlet and exhaust valves is a process which are timed to achieve maximum engine efficiency by completing the various strokes engine cycle at predetermined time intervals. Theoretically both the valves, inlet and exhaust should open at TDC and BDC respectively. Similarly, the exhaust valve should remain open till the piston reaches to TDC during the exhaust stroke and it should be closed fully at TDC. But in practice, due to inertia the valves can not be opened and closed instantaneously and it is not desired even as the intake of air/air-fuel mixture and exhaust of burnt gases are required to be completed. The periodic opening and closing of inlet and exhaust valves is known as valve timing.

The inlet valves is generally opened before 100 of TDC which is known as valve lead and closes almost 460 after BDC which refers to valve lag. Similarly, the exhaust valve is opened before 460 of BDC and closed after 100 of TDC. The condition when both the inlet and exhaust valves are open simultaneously is called valve overlap. The valves are opened and closed according to the valve timing diagram. The cam shaft which is run through timing gears rotates at half of the number of rotations per minute of the crankshaft. The valve mechanism is generally classified by the method of valve arrangement as either side valve or over head valves. The overhead valve arrangement is the most commonly used arrangement these days.

The opening of inlet valve is advanced to use the depression made by the outgoing gases and hence the fresh air is taken inside the cylinder. But, if the inlet valves are opened very advanced, it may make some of the exhaust gases to re-enter in the cylinder through the inlet manifold. Similarly, the closer of the inlet valve is made later than the BDC when the piston has already stated moving up for the compression stroke, this is done to achieve the maximum volumetric efficiency.

Ideally, the exhaust valve should be opened after the piston reaches BDC on completion of the power stroke, but the exhaust valve starts opening well before the piston reaches BDC. This makes the exhaust gases to escape from the cylinder with its own energy and hence reduces the work to be done during the exhaust stroke. The closure exhaust valve is delayed to the piston reaches TDC making fully removal of burnt gases and creating partial vacuum inside. But, if the closure of exhaust valve is delayed more, it would result into loss of fresh air also through the exhaust valve. Thus the advantage of valve overlap is obtained to achieve maximum engine efficiency.