Site pages

Current course

Participants

General

Module 1. Classification of Farm Power Sources

Module 2. Classification of IC Engines & Therm...

Module 3. Performance Characteristics

Module 4. Engine Components

Module 5. Engine Operating System

Module 6.:Engine Fuel System

Module 7. Engine Governor

Module 8. Engine Cooling & Lubrication system

Module 9. Engine Ignition System

LESSON 17. Carburetor

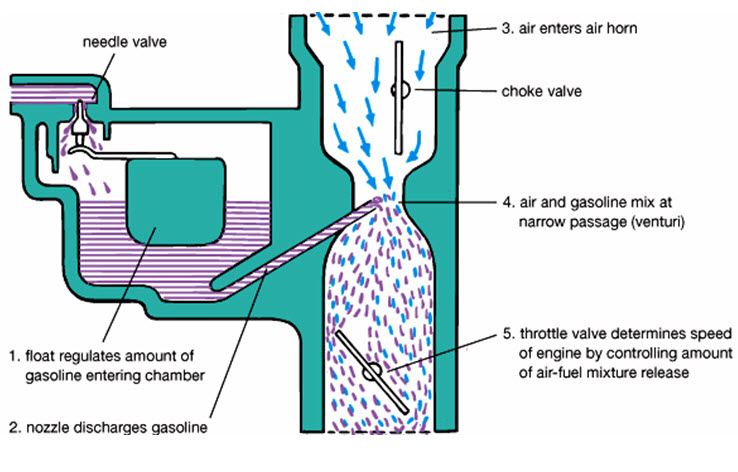

Carburetor is the device which works on Bernoulli’s Principle and is used in petrol engines to controls the amount of atomized fuel and air in the air fuel mixture to be supplied to engine combustion chamber. Carburetor is provided with the throat in which the air stream flows. The velocity of air is more in the throat as compared to velocity at the entrance and this high velocity reduces the pressure inside the throat which makes the fuel to enter in the throat due to pressure difference and gets mixed with the air stream. Under all conditions, the engine carburetor must perform the following:

-

Regulate the airflow in the engine

-

Supply the required amount of fuel to maintain the level of fuel/air mixture

-

Prepare the exact fuel and air mixture

Following are the components of carburetor :

- Float chamber and float

- Venturi

- Nozzle

- Throttle valve

- Fuel jet

- Choke

Float Chamber and float : Special purpose light weight brass metal is used in the float chamber to maintain the constant level fuel in the float chamber. The float is attached to the stopper like mechanism to allow and restrict the entry of fuel in the chamber as it moves down and up. The metallic floats have tendency to get damaged and leak from the joints. So to avoid this, plastic or rubber material is used for manufacturing float. The level of fuel in the float chamber is maintained lower than the nozzle outlet.

Venturi : The fuel from the nozzle flows into the venturi, which is simply a restriction in the air passage. Venturi is the area where this passage area in the direction of air flow is minimum. As the passage for area decreases, it increases the air velocity and hence decreases the air pressure. Due to this depression in the pressure, the fuel comes out from the nozzle and gets mixed with the air and converted into fuel vapours. Then, this air fuel mixture is entered into the engine cylinder through inlet manifold. The quantity of fuel entering into the engine cylinder depends upon the jet size, float level and venture vacuum.

Nozzle : It is used in the venturi to discharge the fuel and get mixed with the air stream. The nozzle outlet is place above the level fuel in the float chamber to avoid spilling of fuel from the nozzle when vehicle is running on slope and highly cambered roads.

Throttle valve : It is used to control the quantity of flow of air fuel mixture. Throttle valve is attached to the accelerator pedal through lever mechanism. Butterfly or cylindrical valves are used but butterfly type is most commonly used valve for controlling the air fuel mixture. Butterfly type is simply a disc type mechanism hinged at the centre. Although it is easy use and operate, but it restricts the flow even when it is fully opened. No suction is applied to the nozzle when the throttle valve is fully closed.

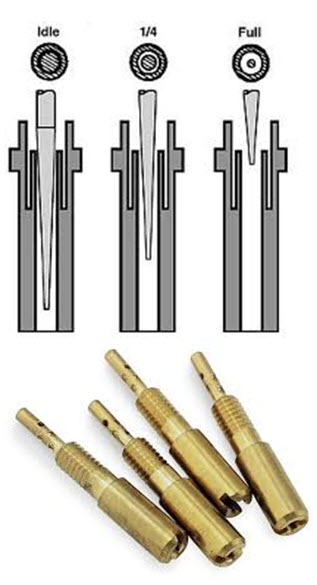

Fuel jet : The flow of fuel from the float chamber to the venture through the nozzle is metered by fuel jet. It regulates the fuel supply. Fuel jets are made of special brass material and should have anti corrosive material. The engine idle speed and corresponding idling mixture is adjusted with the help of stop screw provided on the top of jet. Idle speed of an engine is adjusted by stop screw at the point where engine runs smoothly on the slowest speed at no load. Main jet adjustments are done after the engine is warmed up and put on load. When engine runs at full throttle, the main jet is turned until the full power is regained and engine runs smoothly. The jet screw is rotated further (to almost half turn more) to avoid engine stalling due to load variations.

Choke : It is a butterfly valve operated by hand lever or sometimes automatic to restrict the air flow and hence increasing the proportion fuel in air fuel mixture. The choke is generally applied for initial starting purposes. The choke is to be opened immediately when the engine gets started otherwise the flooded fuel would result into engine stall. Carburetor can be of following three types on the basis of direction of air-fuel mixture is supplied :

i) Up-Drought

ii) Down-Drought

iii) Horizontal

Out of above mentioned types of carburetors, down-drought is the most commonly used type due to following advantages :

i) Fuel flows dues to gravity which helps the engine under load to run smoothly at lower speed

ii) Volumetric efficiency can be enhanced and it is easy to access