Site pages

Current course

Participants

General

Module 1. Classification of Farm Power Sources

Module 2. Classification of IC Engines & Therm...

Module 3. Performance Characteristics

Module 4. Engine Components

Module 5. Engine Operating System

Module 6.:Engine Fuel System

Module 7. Engine Governor

Module 8. Engine Cooling & Lubrication system

Module 9. Engine Ignition System

LESSON 22. Need of Governor : Function and Working Principle

22.1 Need

In petrol engines, the carburetor controls both air and fuel delivery at various speed and load conditions. However, in diesel engines, governor is the device used to control the engine speed. Governor regulates the engine speed by varying the fuel flow as per the load conditions. Engine speed tends to overshoot to hazardous values on reduction of load and also to very low speed (almost on the stage of engine halt) on increase in sudden and unexpected load application. To avoid such conditions, the engine speed is controlled by regulating the fuel supply by using engine governor. All injection pumps operate in conjunction with the governor. Generally, when the engine speed increases, the air intake decreases and hence results in more injection of fuel. On the other hand, at idling speed (no load conditions) or when the engine speed is relatively low, the fuel supply is also minimum. A governor is, therefore, a necessity to control the fuel injected to ensure optimum conditions at all speeds and loads within the range specified. A governor capable of holding any speed between idling and maximum speed is called variable speed governor.

22.2 Working principle

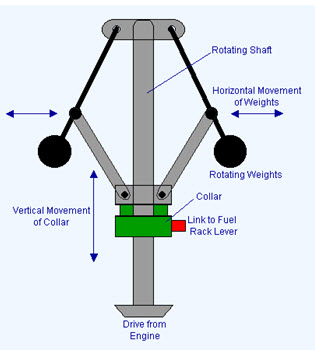

The basic principle of working of governor is that the governor spring and flyweights are so selected that at any designed engine speed centrifugal force and spring force are in equilibrium. If the speed increases, the increasing centrifugal force of the flyweights acts through the system of levers to reduce the delivery of fuel and when the speed decrease, the control rod moves to step up the fuel delivery rate to increase the speed to desired level. The governor maintains all speeds automatically including idling and minimum speed. Governors are often included in the design of the fuel injection pump. The diesel engine governors should have following certain qualities or characteristics.

Isochrones : It should maintain engine speed at constant value regardless of the load.

Stability : Governor should maintain the desired speed without variation. If the governor is not stable, the speed will swing back and forth around the desired value which is known as hunting. A governor with a high degree of precision or stability is known as a “dead deal” governor.

The speed variation from no load to full load is known as “steady state regulation” or speed drop or RPM (revolution per minute) drop.

Speed drop = (S1 – S2)/S2 * 100

Where, S1 = No load speed

S2 = Rated full load speed

Similarly, to determine the sensitivity of governor, the degree of unbalance is evaluated at maximum speed.

Percent of unbalance : (S1 – S2)/S3 * 100

Where, S3 = (S1+S2)/2