Site pages

Current course

Participants

General

Module 1. Moisture content and its determination.

Module 2. EMC

Module 3. Drying Theory and Mechanism of drying

Module 4. Air pressure within the grain bed, Shred...

Module 6. Study of different types of dryers- perf...

Module 5. Different methods of drying including pu...

Module 7. Study of drying and dehydration of agric...

Module 8. Types and causes of spoilage in storage.

Module 9. Storage of perishable products, function...

Module 10. Calculation of refrigeration load.

Module 11. Conditions for modified atmospheric sto...

Module 12. Storage of grains: destructive agents, ...

Module 13. Storage of cereal grains and their prod...

Module 14. Storage condition for various fruits an...

Module 15. Economics aspect of storage

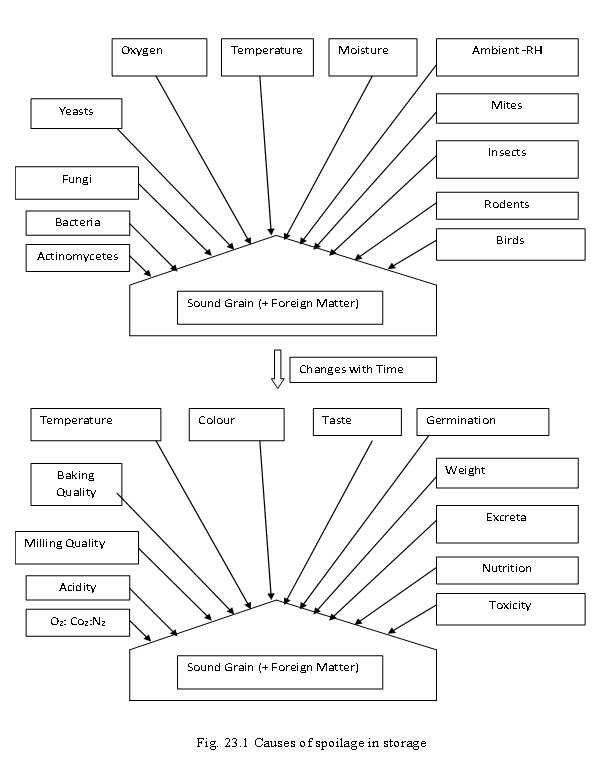

Lesson 23. Causes of spoilage in storage

Following are the various sources causing spoilage in the stored food and corrective measures are required to be exercised to minimize the effect to alleviate the effects.

23.1 Mechanical Damage

Causes

incorrect harvesting methods

Poor handling, threshing, shelling, cleaning, sorting or drying

Bad transport and loading practices (e.g. use of hooks)

Effects

Losses in weight

Losses in quality (germination power, nutritional value)

increased vulnerability to infestation from insect pests, fungi and rodents

Countermeasures

Pay attention to maximum temperatures when drying

Use safe techniques in harvesting, transport, processing and storage

Take care when handling bags

Repair or replace damaged bags

Do not use hooks to carry bags

Repair pallets (e.g. protruding nails!)

23.2 Heat

Causes

Unsuitable storage structures (false location, insufficient shade and ventilation facilities, lack of heat insulation)

Mass reproduction of storage pests and fungi

Lack of aeration of store

High moisture content of the grain

Effects

Losses in weight

Losses in quality (nutritional value, germination power)

Good conditions for pest development

Condensation with subsequent development of fungi

Countermeasures

Build suitable storage structures

Provide shade for stores or silos (e.g. by means of wide eaves or shading trees)

Keep temperatures as low as possible (aerate storage facility)

Conduct treatments for pest control

Store bags on pallets in order to improve aeration

Maintain spaces of 1 m around all bag stacks

23.3 Moisture

Causes

insufficient drying before storage

High relative humidity

Constructional faults and damage to the store (unsuitable materials, unsealed floor, walls and roof, holes, gaps, etc.)

imbalances in temperature (e.g. day/night) in storage facility with subsequent condensation

Produce stored on the floor or touching the walls

Mass reproduction of pests

Effects

Losses in quality

Losses in weight

Development of fungi and formation of mycotoxins

improved conditions for the development of pests

Swelling and germination of seeds

Damage to storage structures

Countermeasures

Dry produce sufficiently before storage

Repair and seal storage facility

Keep relative humidity as low as possible in storage facility (perform controlled ventilation)

Store bags on pallets

Maintain spaces of 1 m around all bag stacks

Conduct pest control treatments

Avoid temperature fluctuations (day/night) in store by means of shade and ventilation

23.4 Insect Pests

Causes of infestation

- introduction of infested lots

- Cross infestation from neighboring lots or stores

- Migration from waste or rubbish

- Hiding places in stores (cracks, fissures)

- Use of infested bags

Effects

Losses in weight

Losses in quality (impurities such as droppings, cocoons and parts of insects, reduction of nutritional value, reduction in germination power)

increase of temperature and moisture

Countermeasures

Harvest at the right time

Choose tolerant varieties

Keep means of transportation clean

Remove infested cobs, panicles or pods before storage

Ensure that produce is dry before storing

Prevent pest introduction by checking for infestation before storing

Clean the store daily

Keep the temperature and relative humidity as low as possible (perform controlled ventilation)

Prevent any pest infiltration by sealing the store (windows, doors, ventilation facilities; e.g. with the use of insect gauze)

Repair any damage to the store immediately

Store old and new lots separately

Clean empty bags thoroughly and treat them against insects if necessary

Perform pest control treatments

Rotate stocks: 'first in first out'

23.5 Microorganisms

Causes of infestation

High moisture content of stored produce

High relative humidity in store

Condensation

Humidity and moisture produced by insects

Effects

Loss of quality (smell, taste, colour, nutritional value, germination power)

Formation of mycotoxins

Slight loss of weight (mould)

Further increase in temperature and moisture

Further condensation

Countermeasures

Dry produce sufficiently before storage

Keep relative humidity as low as possible in storage facility (perform controlled ventilation)

Store bags on pallets

Maintain spaces of 1 m around all stacks

Conduct pest control treatments

23.6 Rodents

Causes of infestation

Penetration through badly closing doors, windows, ventilation openings, holes

Lack of barriers

Lack of hygiene in store and surrounding area (possible hiding and breeding places)

Effects

Loss of weight

High losses in quality due to contamination of produce with faeces and urine

Contamination of produce with pathogenic agents (typhoid, rabies, hepatitis, plague, etc.)

Damage of material and facilities (bags, doors, electric cables)

Countermeasures

Prevent entry of rodents by sealing store rat-proof

Keep store and surrounding area clean

Place traps

Carry out rodent control measures

23.7 Birds

Causes of infestation

- Open or broken doors, windows, ventilation openings or roofs

Effects

Losses in weight

Damage to bags

Contamination of stored produce with droppings and pathogenic agents

Countermeasures

Bird-proof stores (carry out repair work, fit grilles or nets)

Remove any nests of granivore birds from the store and surrounding area

23.8 References

-

A Text Book of Unit Operations Agricultural Processing by K.M Sahay and K.K.Singh.

-

FAO Corporate document Repository Produced by Agriculture and consumer Protection.

-

Sinha, R.N &Muir. Grain Storage: Part of a System. Avi Publisher.