Site pages

Current course

Participants

General

Module 1. Moisture content and its determination.

Module 2. EMC

Module 3. Drying Theory and Mechanism of drying

Module 4. Air pressure within the grain bed, Shred...

Module 6. Study of different types of dryers- perf...

Module 5. Different methods of drying including pu...

Module 7. Study of drying and dehydration of agric...

Module 8. Types and causes of spoilage in storage.

Module 9. Storage of perishable products, function...

Module 10. Calculation of refrigeration load.

Module 11. Conditions for modified atmospheric sto...

Module 12. Storage of grains: destructive agents, ...

Module 13. Storage of cereal grains and their prod...

Module 14. Storage condition for various fruits an...

Module 15. Economics aspect of storage

Lesson - 31. Respiration, Moisture and temperature changes in stored grains air movement inside the storage.

31.1 Respiration of Grains

Food grains get oxygen from the air and burn food from its endosperm. This process liberates heat, water vapours and carbon dioxide. This process in grains is called respiration. The respiration in grains, during the storage period, causes a dry matter loss of 1% or more.

Respiration is a process of slow combustion of carbohydrates in presence of oxygen in living system to produce the energy.

C6H12O6 + 6O2 → 6CO2 + 6H2O + Energy

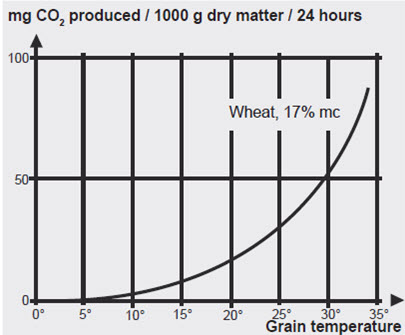

This process is affected by temperature and concentration of O2 and CO2. Decreasing the concentration of O2 and increasing concentration of CO2 reduces the rate of respiration. A decrease in temperature slows down the respiration rates in grains like many other foods.

Respiration has long been used to measure metabolic activity in stored produce. Its rate is governed by water availability, temperature, oxygen concentration, microbial contamination, mechanical damage, the conditions and period of previous storage and by mites and insect infestation. Microorganisms, especially fungi, are important causes of deterioration and grain also respires but the relative contributions of these two components to total respiration remain controversial. Some studies. using maize with 22-27% water content, have suggested that grain respiration greatly exceeds microbial respiration. While others have found relatively low and constant levels of respiration in mould-free wheat grain at 12-35% water content. Respiration rates may differ with the cultivar, age and quality of grain tested, between different methods of determining respiration, the quantity of grain used and the period of the experiment.

Dry matter loss results from the utilization of carbohydrate during respiration. Consequently, respiration data can also be used to measure dry matter loss. Estimates differ as to how much dry matter loss is allowable before grain is rejected. A loss of 0.5% dry matter, sometimes with no visible moulding, was sufficient to render maize grain unfit for use. Considered grain still to be fit for animal feed with dry matter losses up to 2% and decreased germinability, while for seed considered 0.5 % an aceptable or even a small dry matter loss. Dry matter loss up to 1 % over a period of 12 months is acceptable in grain for food use. However, measurement of such small losses directly by weighing is subject to errors because the weight of fungal mycelium on the grain needs to be subtracted from the total dry matter.

An innovative electrolytic respirometer, designed to monitor respiration in soil. Recently became available and has been used to study respiration in cereal grains. This enables the continuous monitoring of oxygen uptake and measurement of total carbon dioxide production during experiments with cereal grains at different water activities and temperatures.

31.2 Moisture and temperature changes in stored grains air movement inside the storage.

The migration of moisture in stored grain takes place due to change in temperature as per season i.e. winter and summer. One of the most important factors influencing storage life of the grain is moisture content. High moisture content and a warm climate promote mold growth, insect growth and increase rate of respiration of grains and due to this deterioration and losses of the stored grains takes place. Moisture migration takes place in stored bin even though the grains are stored at a desired moisture level i.e. safe for storage.

31.2.1 Air movement and migration of moisture inside storage bin in winter season

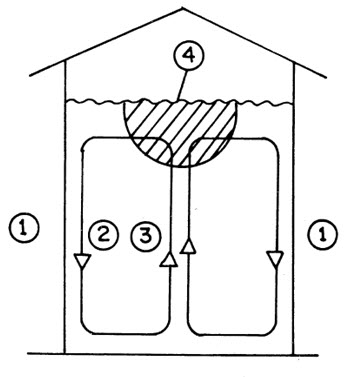

The grains after harvest in summer is stored in storage bin, grains become warm. When winter season comes, the atmospheric temperature is lowered down. The grain stored in summer is warmer than the atmospheric temperature. In this condition after passage of time the air at the surface of storage bin is cools because the outside temperature is lower than the temperature in the centre of bin due to the grains are warmer. The cool air at inside surface of bin moves down along the edge of the bin, across the bottom and then upward near the centre of the bin, where the air and grain are warm. The cool air moving through the centre of the bin picks up moisture from the grains and moves across the top of the sides. At this location the surface of the grain is cold and the moisture condenses on the grain at top surface and consequently the moisture content of grain at top surface is raised. Because of increased grain moisture, spoilage takes place at top of the bin. (Fig.31.2)

1. Atmospheric cool temperature 2. Cool grain at surface of bin

3. Warm grain at centre of bin 4. Moisture accumulation

Fig.31.2 Spoilage of food grains due to temperature changes in winter season

31.2.2 Air movement and migration of moisture inside storage bin in summer season

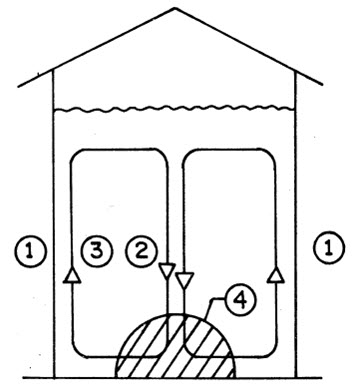

Winter season over and summer season starts, the atmospheric temperature is higher. The grain stored in winter is cooler than the atmospheric temperature. Such grain is stored, after sometime the temperature of air in the grain along the surface rises. The atmospheric temperature in spring and later on rises. As a result air currents move top to bottom through the centre of the bin because at top of the bin the grain is warmer due to higher atmospheric temperature. The hot air at inside top surface of bin moves down at the centre to the bottom of bin and then upward near the surface edge of the bin, where the air and grain are warm. The hot air moving through the centre of the bin picks up moisture from the cool grains and moves across the bottom of the bin. The moist air condenses due to cool grain and moisture accumulation at bottom. Because of increased grain moisture, spoilage takes place at bottom of the bin. (Fig. 31.3)

1. Atmospheric hot temperature 2. Cool grain at centre of bin

3. Warm grain at surface of bin 4. Moisture accumulation

Fig.31.3 Spoilage of food grains due to temperature changes in summer season

References:

-

Respiration and losses in stored wheat under different Environmental conditions by J. Lacey, A. Hamer and N. Magan

-

A Text Book Unit Operations of Agricultural Processing by K.M Sahay and K.K.Singh

-

http://www.los-seibos.com/teoria/GrainBiology.pdf