Site pages

Current course

Participants

General

Module 1. Moisture content and its determination.

Module 2. EMC

Module 3. Drying Theory and Mechanism of drying

Module 4. Air pressure within the grain bed, Shred...

Module 6. Study of different types of dryers- perf...

Module 5. Different methods of drying including pu...

Module 7. Study of drying and dehydration of agric...

Module 8. Types and causes of spoilage in storage.

Module 9. Storage of perishable products, function...

Module 10. Calculation of refrigeration load.

Module 11. Conditions for modified atmospheric sto...

Module 12. Storage of grains: destructive agents, ...

Module 13. Storage of cereal grains and their prod...

Module 14. Storage condition for various fruits an...

Module 15. Economics aspect of storage

Lesson 45. Cold Storage Of Fruits And Vegetables

45.1 Introduction

Deterioration of fruits and vegetables during storage depends largely on temperature. One way to slow down this change and so increase the length of time fruits and vegetables can be stored, is by lowering the temperature to an appropriate level. It must be remembered that if the temperature is too low the produce will be damaged and also that as soon as the produce leaves the cold store, deterioration starts again and often at a faster rate.

45.2 Harvesting

It is essential that fruits and vegetables are not damaged during harvest and that they are kept clean. Damaged and bruised produce have much shorter storage lives and very poor appearance after storage. Dirty produce can introduce pests and moulds into the store.

The produce should be harvested carefully using a sharp stainless steel knife. The fruits and vegetables should not be placed on the ground where they could pick up dirt. Either a clean harvesting basket or clean mats should be used.

It is essential that the fruits and vegetables are harvested at the correct harvesting time.

45.3 Handling

It is important that the produce does not get dirty or damaged during handling. Careful handling should be the rule. The best option is for the produce to be prepared for storage in the field and placed carefully in the storage containers used in the cold store. This considerably reduces the amount of handling and will keep damage to a minimum. It is essential that the produce is handled and placed in the store as quickly as possible as delays between harvesting and cooling can substantially reduce storage life.

45.4 Preparation

If the produce is dirty it should be cleaned before storage. The water used has to be kept clean or fungus spores will be spread throughout the produce. Some fruit and vegetables need their outer leaves removed before storage. However, usually it is better to leave the leaves on during storage to reduce moisture loss, and then remove them before sale.

45.5 Preliminary cooling (Pre-cooling)

Dipping the produce in cool water to remove field heat can reduce the energy requirements of the store. However, this can spread fungus spores throughout the produce. A suitable alternative is to pick the produce either early in the morning when it is cool or late in the evening and leave it overnight to cool down.

45.6 Storage conditions

45.6.1 Temperature

All fruits and vegetables have a 'critical temperature' below which undesirable and irreversible reactions or 'chill damage' takes place. Carrots for example blacken and become soft, and the cell structure of potatoes is destroyed. The storage temperature always has to be above this critical temperature. One has to be careful that even though the thermostat is set at a temperature above the critical temperature, the thermostatic oscillation in temperature does not result in storage temperature falling below the critical temperature. Even 0.5°C below the critical temperature can result in chill damage.

Table 1: Storage conditions for various fruits and vegetables

|

|

Temperature oC |

Relative Humidity % |

Maximum Storage time Reccomended (ASHARE handbook 1982)

|

Storage time in cold stores for vegetables in Tropical countries |

|

Apple |

0-4 |

90-95 |

2-6m |

|

|

Beetroot |

0 |

95-99 |

|

|

|

Cabbage |

0 |

95-99 |

5-6m |

2m |

|

Carrots |

0 |

98-99 |

5-9m |

2m |

|

Cauliflower |

0 |

95 |

2-4w |

1w |

|

Cucumber |

10-13 |

90-95 |

|

|

|

Eggplant |

8-10 |

90-95 |

|

|

|

Lettuce |

1 |

95-99 |

|

|

|

Leeks |

0 |

95 |

1-3m |

1m |

|

Oranges |

0-4 |

85-90 |

3-4m |

|

|

Pears |

0 |

90-95 |

2-5m |

|

|

Pumpkin |

10-13 |

70-75 |

|

|

|

Spinach |

0 |

95 |

1-2w |

1w |

|

Tomatoes |

13-21 |

85-90 |

|

|

It can be seen from the table that there are basically three groups of fruit and vegetables: those stored at 0 - 4°C; those stored at 4 - 8°C; and those that require a storage temperature above 8°C. It is often more convenient to concentrate on one of these groups.

45.6.2 Relative humidity

For most produce, a high but not saturated, relative humidity is required, eg 85 - 95%. Table1 shows specific relative humidities for fruits and vegetables. There is always some moisture loss during cold storage but excessive moisture loss is a problem. It is essential that the relative humidity is kept above 85%. This can be done by:

allowing the produce to reach storage temperature and then covering in plastic

sprinkling the produce with water, this should be done before storage since if the vegetables are sprinkled during storage condensation occurs at the refrigeration unit.

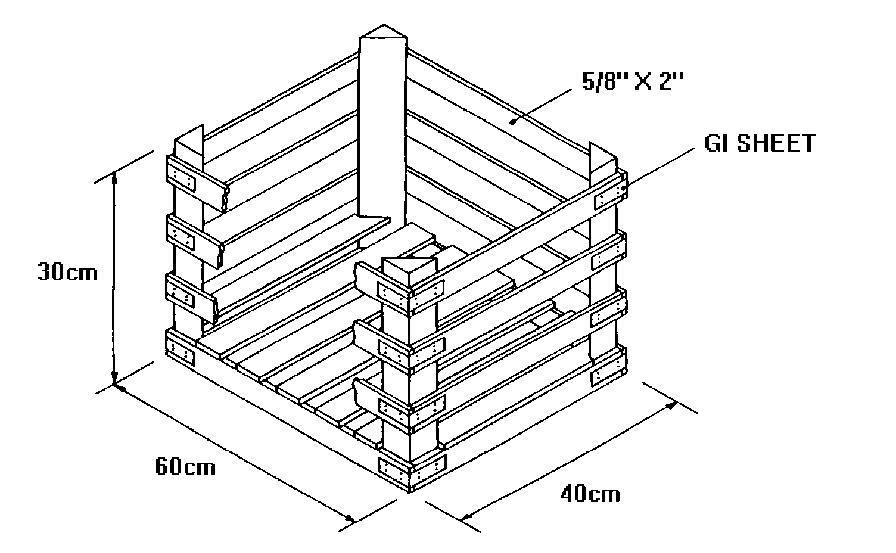

45.7 Packing system

A packing system is required so that the produce can be loaded and unloaded easily and safely. This can be a system using crates that can be stacked or a more complicated system using racks and trays. It is important that the crates are small enough to be moved easily when full of vegetables; are able to be easily and safely stacked; and are strong enough to hold the weight of the other crates. It is essential that the airflow is not restricted, therefore a two foot gap should be left between the walls and the crates and three foot gap left between the crates, the ceiling and refrigeration units. Figure 45.1 shows the design of a crate that is suitable for cold stores. For small-scale cold storage systems, stackable crates are the most appropriate packing system.

The layout plan for the crates needs to be simple and clear so that produce can be removed easily and quickly.

45.8 Length of storage

Table 1 gives the maximum storage times recommended by various organizations. These recommendations are based on figures from Europe and America and are often for too long for small-scale stores in tropical countries for the following reasons:

It is often difficult to prevent delays between harvest and storage.

The produce is often bruised during harvest and loading of the store.

Transport can be bumpy and result in damage.

The temperature of the retail outlets is far higher than for the retail outlets in Europe and America.

45.9 Incompatibility

If different produce is being stored in the same room there is a risk of transfer of odours or ethylene. Table 2 shows the more important incompatibilities.

Table 2: Compatibility of storage

|

Y = No cross action SR = Slight danger BR = Danger N = Cross action will take place

45.10 Operation of the cold store

The cold store should be kept very clean and the doors opened as little as possible.

45.11 Transport

Care needs to be taken during the unloading of the cold store and during transport. If the produce can be transported in the same crates they were stored in, handling and concomitant damage will be reduced.

45.12 Shelf life

The shelf life of the produce will not be as long as fresh produce but if the above recommendations are followed, the reduction in shelf life can be as little as 10%.

References:

-

Cold storage of Fruits and vegetables, Practical Action Technical Brief.

-

Cold Storage Design & Operation: Some Practical Suggestions, Cooper, Food and

-

Agriculture Organization of the United Nations, 1973.

-

Fruit and Vegetable Processing: FAO Agricultural Services Bulletin 119, Food and Agriculture.